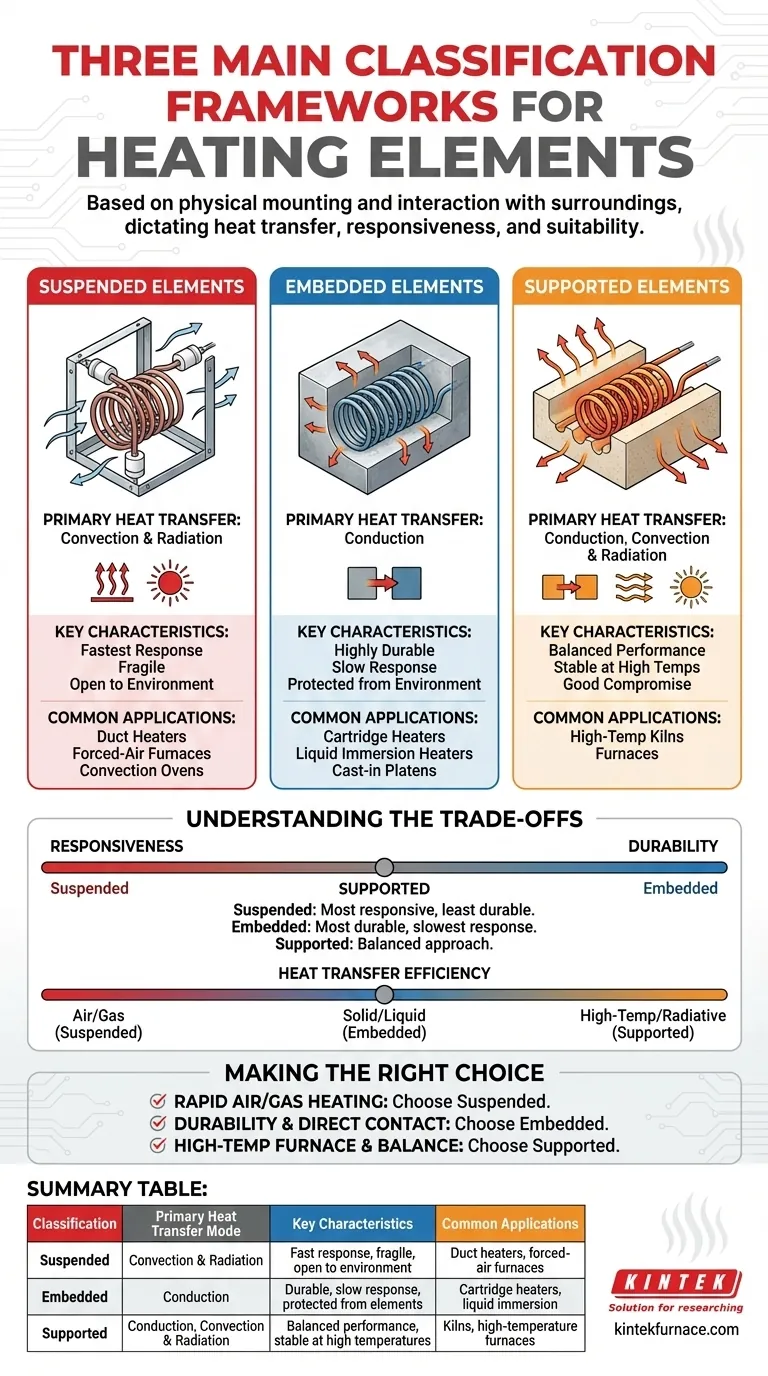

In industrial and commercial applications, heating elements are primarily categorized into three frameworks based on their physical mounting and interaction with their surroundings. These classifications are Suspended, Embedded, and Supported. Understanding the distinction is critical because it directly dictates the element's primary mode of heat transfer, its responsiveness, and its suitability for a given environment.

The classification of a heating element as Suspended, Embedded, or Supported is not just a physical description; it's a direct indicator of its dominant heat transfer mechanism. Mastering this concept is the key to selecting the right element for maximum efficiency, responsiveness, and longevity.

The Three Core Classifications of Heating Elements

The way an element is held in place determines how it sheds its thermal energy. Each classification favors different forms of heat transfer—conduction, convection, or radiation.

Suspended Elements: Maximizing Convection and Radiation

Suspended elements are held in place by ceramic insulators and are otherwise open to the surrounding environment, such as air or another gas.

Because they are unenclosed, they transfer heat very effectively through both convection (heating the surrounding air) and radiation (emitting infrared energy to objects in their line of sight).

This design is common in applications like duct heaters, forced-air furnaces, and convection ovens where rapidly heating a moving gas is the primary goal. Their low thermal mass allows for very fast heat-up and cool-down times.

Embedded Elements: Pure Conduction

Embedded elements are completely encased within an insulating and/or conductive material, such as magnesium oxide, mica, or cast into a metal part.

Their heat must first travel through this encasing material. This means their primary mode of heat transfer to the outside world is conduction. The element heats its sheath, which in turn conducts heat to whatever it is touching.

Examples include cartridge heaters inserted into metal blocks, tubular heaters immersed in liquids, or elements cast directly into aluminum platens. This configuration offers superior protection from moisture, contamination, and physical shock.

Supported Elements: The Hybrid Approach

Supported elements represent a middle ground. They physically rest on or are placed within grooves in a refractory or ceramic material but are not fully encased.

This arrangement allows for a combination of all three heat transfer modes. The element conducts heat to its support structure while its exposed surfaces transfer heat via convection and radiation.

This is a common design in high-temperature kilns and furnaces, where the ceramic structure provides necessary physical support at extreme temperatures while still allowing for efficient radiative heat transfer to the workload.

Understanding the Trade-offs

Choosing a heating element is an exercise in engineering trade-offs. The optimal choice depends entirely on the specific requirements of the application.

Responsiveness vs. Durability

Suspended elements are the most responsive, heating up almost instantly, but they are also the most fragile and susceptible to contamination.

Embedded elements are at the other end of the spectrum. They are extremely durable and protected but have a much slower thermal response due to the mass of the material they are embedded in. Supported elements offer a balance between the two.

Heat Transfer Efficiency

The efficiency of each type is application-dependent. A suspended element is highly efficient for heating air but would be inefficient for heating a solid metal plate.

An embedded cartridge heater is extremely efficient for heating that same metal plate through conduction but would be a poor choice for an open-air heater.

Operating Environment

The intended environment is a critical factor. Suspended elements cannot be used in wet, corrosive, or dirty environments where the element coil could be shorted or damaged.

Embedded elements excel in these harsh conditions, as their resistive coils are completely sealed and protected from the outside world.

Making the Right Choice for Your Application

Use the element's classification as a guide to match its heat transfer characteristics to your primary objective.

- If your primary focus is rapid air or gas heating: Suspended elements offer the fastest thermal response and most direct heat transfer for convective applications.

- If your primary focus is durability and heating a solid or liquid: Embedded elements provide superior protection and reliable conductive heat transfer for direct-contact heating.

- If your primary focus is high-temperature furnace heating with balanced performance: Supported elements provide a good compromise between physical stability and efficient radiative output.

By understanding these fundamental classifications, you can move beyond simple specifications and select an element architecture that truly solves your underlying heating challenge.

Summary Table:

| Classification | Primary Heat Transfer Mode | Key Characteristics | Common Applications |

|---|---|---|---|

| Suspended | Convection & Radiation | Fast response, fragile, open to environment | Duct heaters, forced-air furnaces |

| Embedded | Conduction | Durable, slow response, protected from elements | Cartridge heaters, liquid immersion |

| Supported | Conduction, Convection & Radiation | Balanced performance, stable at high temperatures | Kilns, high-temperature furnaces |

Struggling to select the right heating element for your lab's high-temperature needs? KINTEK specializes in advanced furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our exceptional R&D and in-house manufacturing, we offer deep customization to precisely match your unique experimental requirements. Contact us today to enhance your lab's efficiency and performance with tailored heating solutions!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing