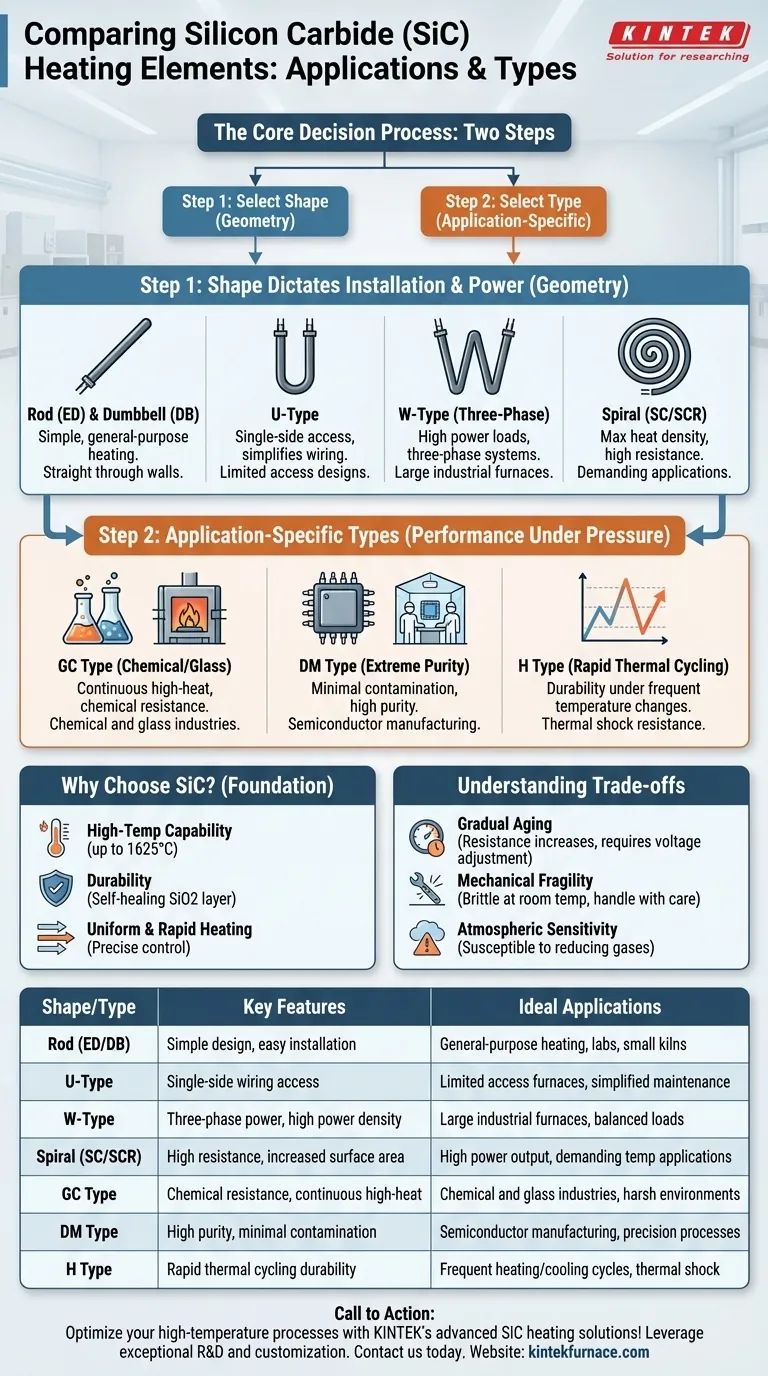

In essence, the choice of a silicon carbide (SiC) heating element depends on a combination of its physical shape and its specific material grade. The element's geometry—such as a simple rod, a U-shape, or a spiral—is chosen to fit the furnace design, power requirements, and wiring access. The material grade or type (like DM or GC) is then selected based on the specific demands of the thermal process, such as the need for extreme purity or resistance to chemical attack.

The core decision is a two-step process: first, select an element shape (Rod, U, W, Spiral) that matches your furnace's physical layout and power needs. Second, select a specialized type (GC, DM) only if your application involves unique environmental challenges like chemical exposure or the need for extreme purity.

The Foundation: Why Choose Silicon carbide?

Before comparing types, it's important to understand why SiC is a benchmark material for high-temperature heating. Its properties make it a reliable and efficient choice for demanding industrial and laboratory environments.

High-Temperature Capability

SiC elements operate effectively at temperatures where many metallic elements would fail, often reaching up to 1625°C (2957°F). This makes them ideal for processes like metal heat treating, sintering ceramics, and glass manufacturing.

Durability and Long Service Life

These elements form a protective glassy layer (silicon dioxide) during operation, which shields them from chemical attack and oxidation. This self-healing property contributes to a long, predictable service life even in harsh furnace atmospheres.

Uniform and Rapid Heating

SiC provides excellent thermal uniformity and can handle rapid heating and cooling cycles. This allows for precise temperature control and increased process throughput, which is critical in applications from laboratory testing to large-scale industrial production.

Decoding Element Geometry: Shape Dictates Installation and Power

The most immediate difference between SiC elements is their physical shape. This choice is primarily driven by the furnace's design, available space, and electrical requirements.

The Workhorse: Rod (ED) and Dumbbell (DB) Elements

These are the simplest forms—straight rods, often with thickened, lower-resistance ends (dumbbell style) for the terminals. They are installed straight through the furnace walls and are ideal for straightforward, general-purpose heating.

For Single-Side Access: U-Type Elements

A U-Type element is essentially two rods connected at the bottom, forming a "U" shape. Its key advantage is that both electrical connections are on the same side of the furnace. This dramatically simplifies wiring and is invaluable for designs where access is limited.

For High Power Loads: W-Type (Three-Phase) Elements

Shaped like a "W," this element consists of three SiC rods connected to a common bridge. It is designed specifically for three-phase electrical systems, providing a balanced load and higher power density. This makes it a common choice for larger industrial furnaces.

For Maximum Heat Density: Spiral (SC and SCR) Elements

Spiral elements feature grooves cut into the rod to form a spiral heating section. This increases the electrical resistance and surface area within the same length, allowing for significantly higher power output and operating temperatures. Double spiral (SCR or SGR) types offer even greater power density for the most demanding applications.

Application-Specific Types: Performance Under Pressure

Beyond shape, certain SiC elements are manufactured with specific properties or coatings to excel in unique operating conditions.

For Continuous High-Temperature Use: GC Type

The GC Type is formulated for superior performance in continuous, high-heat processes, particularly in the chemical and glass industries. Its composition is optimized for enhanced resistance to the specific chemical vapors and environments found in these applications.

For Extreme Purity and Precision: DM Type

The DM Type is engineered for applications where process contamination is a critical concern, such as in semiconductor manufacturing. These elements use high-purity materials to ensure they do not outgas or introduce impurities into the furnace atmosphere.

For Rapid Thermal Cycling: H Type

While many SiC types handle thermal shock well, the H Type is specifically designed for environments with very rapid and frequent temperature changes. Its internal structure is built to withstand the mechanical stresses induced by fast heating and cooling cycles, ensuring a longer service life.

Understanding the Trade-offs

While highly effective, SiC elements have operational characteristics that must be managed for optimal performance and longevity.

Gradual Aging and Resistance Increase

Over its life, a SiC element's electrical resistance will gradually increase due to oxidation. This is a normal aging process. To compensate, the power supply must be able to increase its voltage output over time to maintain constant power and temperature. Systems often use tap-changing transformers or Silicon Controlled Rectifiers (SCRs) for this purpose.

Mechanical Fragility at Room Temperature

Silicon carbide is a ceramic material. While very strong at high temperatures, it is brittle and fragile at room temperature. Care must be taken during shipping, handling, and installation to avoid cracks or fractures that would lead to premature failure.

Atmospheric Sensitivity

The protective silicon dioxide layer can be compromised by certain furnace atmospheres, particularly reducing gases like hydrogen. In such cases, specialized coatings or selecting a different element type may be necessary to protect the element and ensure a reasonable service life.

Making the Right Choice for Your Furnace

Your selection should be guided by your specific operational goals, balancing furnace design, process requirements, and cost.

- If your primary focus is general-purpose heating in a lab or small kiln: Start with Rod (ED) or U-Type elements for their simplicity, versatility, and ease of installation.

- If your primary focus is high power density in a large industrial furnace: W-Type (three-phase) and Double Spiral (SCR) elements are designed for balanced, high-power loads.

- If your primary focus is a specialized environment like semiconductor or chemical processing: Select an application-specific grade like DM (purity) or GC (chemical resistance) to ensure process integrity.

- If your primary focus is ease of wiring and furnace maintenance: U-Type elements are the ideal choice, as they allow for all connections to be made on one side of the furnace.

Matching the element's geometry to your furnace design and its material type to your process environment is the key to a successful high-temperature system.

Summary Table:

| Shape/Type | Key Features | Ideal Applications |

|---|---|---|

| Rod (ED/DB) | Simple design, easy installation | General-purpose heating, labs, small kilns |

| U-Type | Single-side wiring access | Limited access furnaces, simplified maintenance |

| W-Type | Three-phase power, high power density | Large industrial furnaces, balanced loads |

| Spiral (SC/SCR) | High resistance, increased surface area | High power output, demanding temperature applications |

| GC Type | Chemical resistance, continuous high-heat use | Chemical and glass industries, harsh environments |

| DM Type | High purity, minimal contamination | Semiconductor manufacturing, precision processes |

| H Type | Rapid thermal cycling durability | Frequent heating/cooling cycles, thermal shock resistance |

Optimize your high-temperature processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need robust SiC elements for sintering, glass production, or semiconductor processing, KINTEK delivers reliable performance and enhanced efficiency. Contact us today to discuss how we can elevate your laboratory's capabilities and achieve superior results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance