The primary advantage of using a tube furnace Chemical Vapor Deposition (CVD) system for this application is the integration of annealing and growth into a single, seamless workflow. By combining these steps, you eliminate the need for intermediate sample transfers and the expensive, complex high-vacuum equipment typically associated with Physical Vapor Deposition (PVD). This method significantly reduces operational costs while enabling the production of centimeter-scale, single-crystal Cu(111) substrates, effectively bypassing the size and cost limitations of commercial copper sheets.

Core Insight: The tube furnace CVD method is superior for Cu(111)/graphene heterojunctions because it solves the "transfer problem." It allows you to thermally treat the copper to achieve a single-crystal structure and immediately grow graphene on top of it within the same environment, ensuring a pristine interface and high-structural integrity without breaking vacuum.

Streamlining the Production Process

Integrated Annealing and Growth

The most critical technical benefit of the tube furnace system is the consolidation of process steps. In a traditional workflow, preparing the substrate and depositing the material often occur in separate stages, potentially exposing the sample to contamination.

A tube furnace allows you to anneal the copper foil to achieve the Cu(111) crystal orientation and immediately proceed to graphene growth. This occurs in a single run, maintaining a controlled environment throughout the fabrication of the heterojunction.

Elimination of High-Vacuum Complexity

Traditional Physical Vapor Deposition (PVD) often requires Ultra-High Vacuum (UHV) environments to maintain purity, which necessitates complex pumps and costly maintenance.

Tube furnace CVD operates effectively without these stringent high-vacuum requirements. This drastically reduces the complexity of the hardware setup and lowers the barrier to entry for producing high-quality heterojunctions.

Simplified Sample Handling

Because the process is consolidated, there is no need to physically move the sample between an annealing oven and a deposition chamber. This removes the risk of physical damage or surface oxidation that can occur during sample transfer, preserving the quality of the Cu(111) surface before graphene deposition.

Quality and Scalability Advantages

Overcoming Substrate Limitations

Commercial single-crystal copper sheets are notoriously expensive and often restricted to small sizes. This creates a bottleneck for scaling up research or production.

Using a tube furnace CVD system allows for the production of large-area single-crystal substrates, reaching sizes up to the centimeter scale. This scalability is essential for moving from theoretical research to practical device applications.

Superior Interface Quality

CVD is a chemical process that relies on surface reactions, leading to molecular-level nucleation. This results in dense, uniform films that conform well to the substrate.

In the context of a heterojunction, this chemical bonding mechanism can produce a stronger bonding force compared to the physical adhesion typical of PVD. This improves the stability and reliability of the final electronic device.

Understanding the Trade-offs

While tube furnace CVD offers clear advantages for this specific application, it is vital to acknowledge the inherent challenges of the method to ensure a balanced perspective.

Complexity of Process Control

While the hardware is simpler than UHV PVD, the chemical process control is more complex. You must precisely manage gas flow rates, temperatures (often up to 1200°C), and pressure to ensure the correct chemical reactions occur.

Safety and Exhaust Management

Unlike PVD, which uses solid targets, CVD utilizes reactive precursor gases. This necessitates robust safety features, including gas flow monitoring and effective exhaust mechanisms to handle toxic or flammable byproducts.

Material Specificity

CVD is restricted to materials that can be deposited via gas-phase reactions. While ideal for graphene and copper, this method is less versatile than PVD if you intend to deposit materials that do not easily vaporize or react in a gaseous state.

Making the Right Choice for Your Goal

To determine if a tube furnace CVD system is the right tool for your specific project, consider your primary constraints:

- If your primary focus is High-Quality Interfaces: Choose tube furnace CVD. The ability to grow graphene directly on freshly annealed Cu(111) without breaking isolation ensures the purest possible heterojunction.

- If your primary focus is Cost and Scalability: Choose tube furnace CVD. It avoids the exorbitant costs of commercial single-crystal substrates and the capital expenditure of UHV PVD equipment.

- If your primary focus is coating Temperature-Sensitive Materials: Exercise caution. Tube furnace CVD requires high temperatures for the annealing and reaction phases, which may not be suitable for all substrates.

Ultimately, for Cu(111)/graphene heterojunctions, the tube furnace CVD offers the optimal balance of large-area scalability, interface purity, and cost-efficiency.

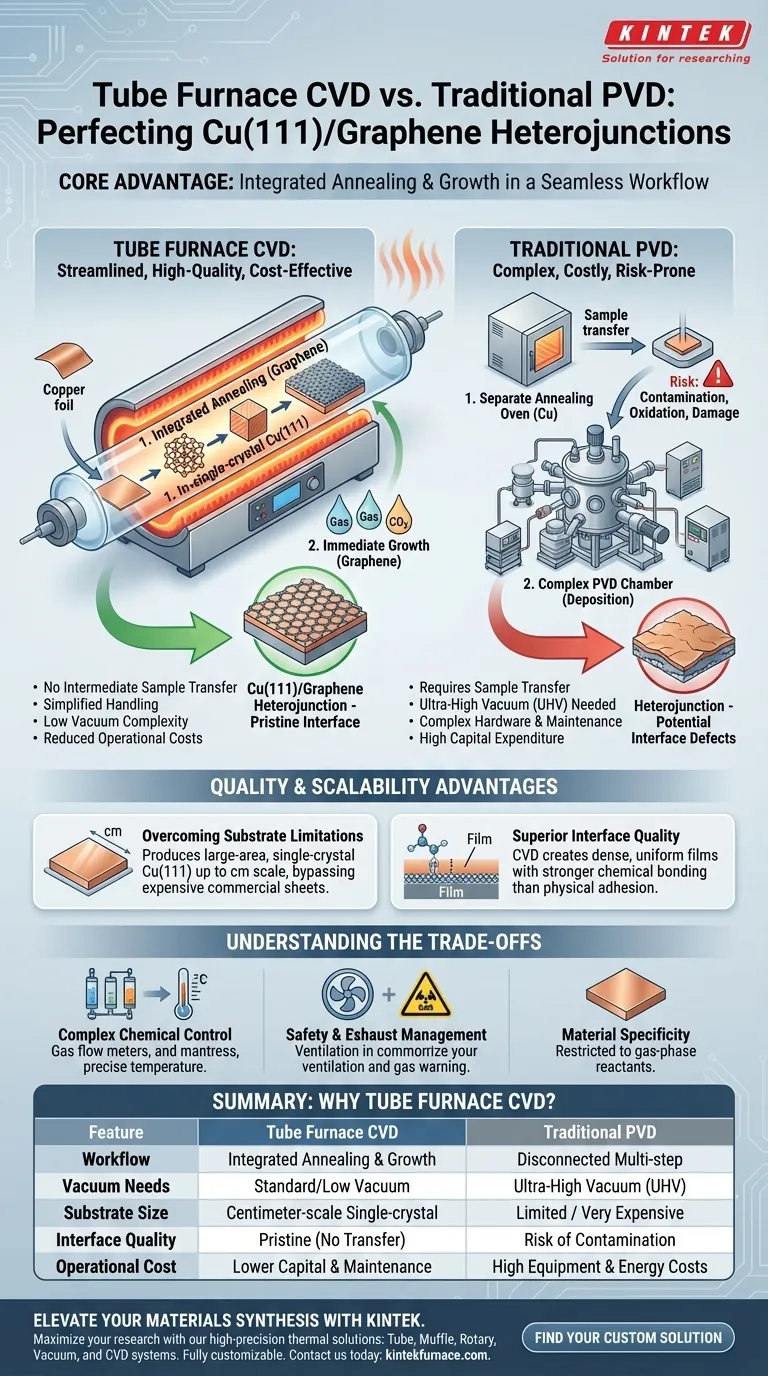

Summary Table:

| Feature | Tube Furnace CVD | Traditional PVD |

|---|---|---|

| Workflow | Integrated Annealing & Growth | Disconnected Multi-step Process |

| Vacuum Needs | Standard/Low Vacuum | Ultra-High Vacuum (UHV) |

| Substrate Size | Centimeter-scale Single-crystal | Often Limited/Very Expensive |

| Interface Quality | Pristine (No Transfer Needed) | Risk of Contamination During Transfer |

| Operational Cost | Lower Capital & Maintenance | High Equipment & Energy Costs |

Elevate Your Materials Synthesis with KINTEK

Maximize your research potential with high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-precision Tube Furnaces, Muffle Furnaces, Rotary, Vacuum, and CVD systems designed to streamline your workflow and ensure superior interface integrity.

Whether you are growing large-area graphene or developing complex heterojunctions, our systems are fully customizable to meet your unique laboratory needs.

Ready to scale your production? Contact us today to find your custom furnace solution.

Visual Guide

References

- Jia Tu, Mingdi Yan. Chemical Vapor Deposition of Monolayer Graphene on Centimeter-Sized Cu(111) for Nanoelectronics Applications. DOI: 10.1021/acsanm.5c00588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the technical advantages of using EPD equipment for SiCf/SiC interface layer preparation? | EPD vs CVD/CVI

- What is the function of a customized spray pyrolysis chamber? Optimize ZnSe and PbSe Thin Film Synthesis

- How does chemical vapor infiltration work? A Guide to High-Performance Composite Manufacturing

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- What are the limitations or challenges of the CVD process? Understand Key Hurdles for Better Decisions

- Why is high-temperature hydrogen (H2) pretreatment necessary for alumina powder? Unlock FB-CVD Excellence

- What role does a trace moisture injection device play in Super-growth CVD? Unlock High-Purity CNT Synthesis

- Why is hydrogen gas used in CVD for graphene growth? Unlock Pristine Catalytic Surfaces