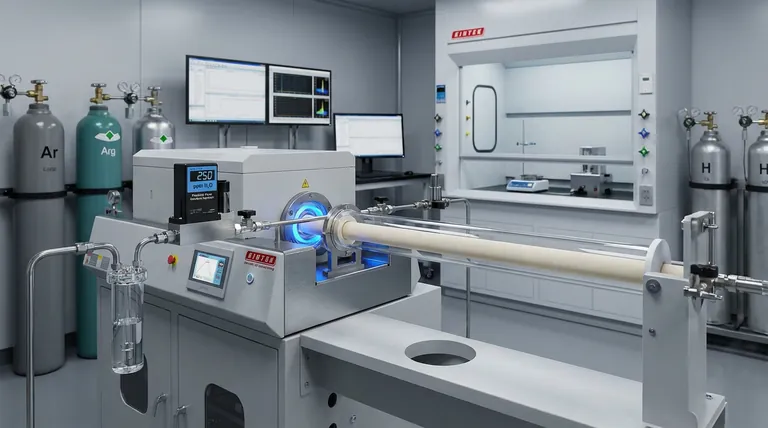

In the water-assisted chemical vapor deposition (CVD) process, the trace moisture injection device acts as a precise regulator of catalyst activity. Its primary role is to introduce a controlled amount of water vapor—typically around 250 ppm—into the growth environment. This moisture functions as a vital growth enhancer, keeping the iron catalyst active far longer than traditional methods allow.

By continuously removing amorphous carbon precipitates from the iron catalyst, trace moisture prevents premature catalyst deactivation. This mechanism is the defining factor that enables the synthesis of long, high-purity, vertically oriented carbon nanotube (CNT) arrays.

The Mechanics of Catalyst Preservation

Selective Cleaning of the Catalyst

The core problem in standard CVD processes is the accumulation of unwanted byproducts. As carbon nanotubes grow, amorphous carbon precipitates tend to build up on the surface of the iron catalyst.

This buildup effectively "chokes" the catalyst. The trace moisture injection device introduces water vapor that acts as a scrubbing agent, reacting with and removing this amorphous carbon without damaging the nanotubes.

Extending Catalyst Lifespan

Because the catalyst surface is kept clean, it remains chemically active for a significantly extended duration.

Without this moisture, the catalyst would quickly become encapsulated by impurities and cease to function. The injection device ensures the iron catalyst retains its ability to facilitate growth throughout the process.

Enabling Vertical Growth

The result of this prolonged activity is structural superiority. The process allows for the growth of vertically oriented CNT arrays on substrates like aluminum nitride.

This orientation and length are direct consequences of maintaining a pristine catalyst surface, which supports sustained, unobstructed nanotube formation.

The Critical Importance of Precision

Why "Trace" Amounts Matter

It is vital to understand that the injection device must deliver controlled amounts of moisture. The target concentration is approximately 250 ppm.

This specific level is a critical operational window. The device serves to balance the environment, ensuring there is enough oxidizer (water) to clean the catalyst, but not so much that it damages the carbon nanotubes or inhibits the reaction.

The Impact of Control on Purity

The precision of the injection device directly correlates to the quality of the final product.

By maintaining the exact moisture levels required, the process minimizes impurities. This leads to higher-purity carbon nanotube arrays, distinguishing the "Super-growth" method from less controlled CVD techniques.

Optimizing for Material Quality

To maximize the effectiveness of the water-assisted CVD process, focus on the precision of your environmental controls.

- If your primary focus is Array Length: Ensure the device maintains a steady 250 ppm to maximize the catalyst's active lifespan, preventing early termination of growth.

- If your primary focus is Material Purity: Rely on the moisture injection to aggressively mitigate amorphous carbon buildup, leaving only the desired nanotube structures.

Mastering the injection of trace moisture is the key to unlocking the full potential of Super-growth CNT synthesis.

Summary Table:

| Feature | Impact of Trace Moisture (250 ppm) |

|---|---|

| Catalyst Function | Removes amorphous carbon to prevent catalyst "choking" |

| Growth Duration | Significantly extends catalyst lifespan for longer arrays |

| Material Purity | Minimizes impurities by selectively cleaning iron catalysts |

| Structural Result | Enables dense, vertically oriented CNT formation |

Master Precision Growth with KINTEK

Achieving the perfect 250 ppm moisture balance requires the highest level of environmental control. KINTEK provides industry-leading CVD systems, vacuum furnaces, and customizable high-temp lab solutions specifically designed to support advanced material synthesis like Super-growth CNTs.

Backed by expert R&D and precision manufacturing, our equipment ensures the stability and control necessary for your unique research needs. Contact KINTEK today to discuss how our customizable systems can elevate your CVD processes and deliver high-purity results.

References

- Naoyuki Matsumoto, Ken Kokubo. Enhancing the Thermal Conductivity of CNT/AlN/Silicone Rubber Composites by Using CNTs Directly Grown on AlN to Achieve a Reduced Filler Filling Ratio. DOI: 10.3390/nano14060528

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is chemical vapor deposition in a CVD furnace? Build Materials with Atomic Precision

- How do IoT gas sensors and Autoencoders contribute to CVD furnace safety? Enhance Pipeline Integrity and Monitoring

- What materials can be deposited using CVD? Unlock Versatile Thin Films for Your Applications

- What are intermetallic compounds, and how are they used in CVD? Unlock Advanced Thin Film Solutions

- What are the environmental benefits of using CVD furnaces? Reduce Waste and Boost Efficiency

- What are the industrial applications of CVD processes? Unlock High-Performance Coatings for Your Industry

- How is polysilicon deposited using CVD? Master LPCVD for High-Purity Semiconductor Films

- What nanomaterials can be synthesized using CVD furnaces? Unlock Versatile Nanoscale Material Creation