While a powerful technique for creating high-quality thin films, Chemical Vapor Deposition (CVD) is not a universal solution. Its primary limitations are the extremely high temperatures required, which restricts material compatibility, and significant operational complexities, including high costs, the need for precision control, and stringent safety protocols due to the use of hazardous gases.

The core challenge of CVD is not its effectiveness but its feasibility. The process produces excellent, uniform coatings, but its demanding operational requirements in temperature, cost, and safety make it a specialized tool rather than a general-purpose coating method.

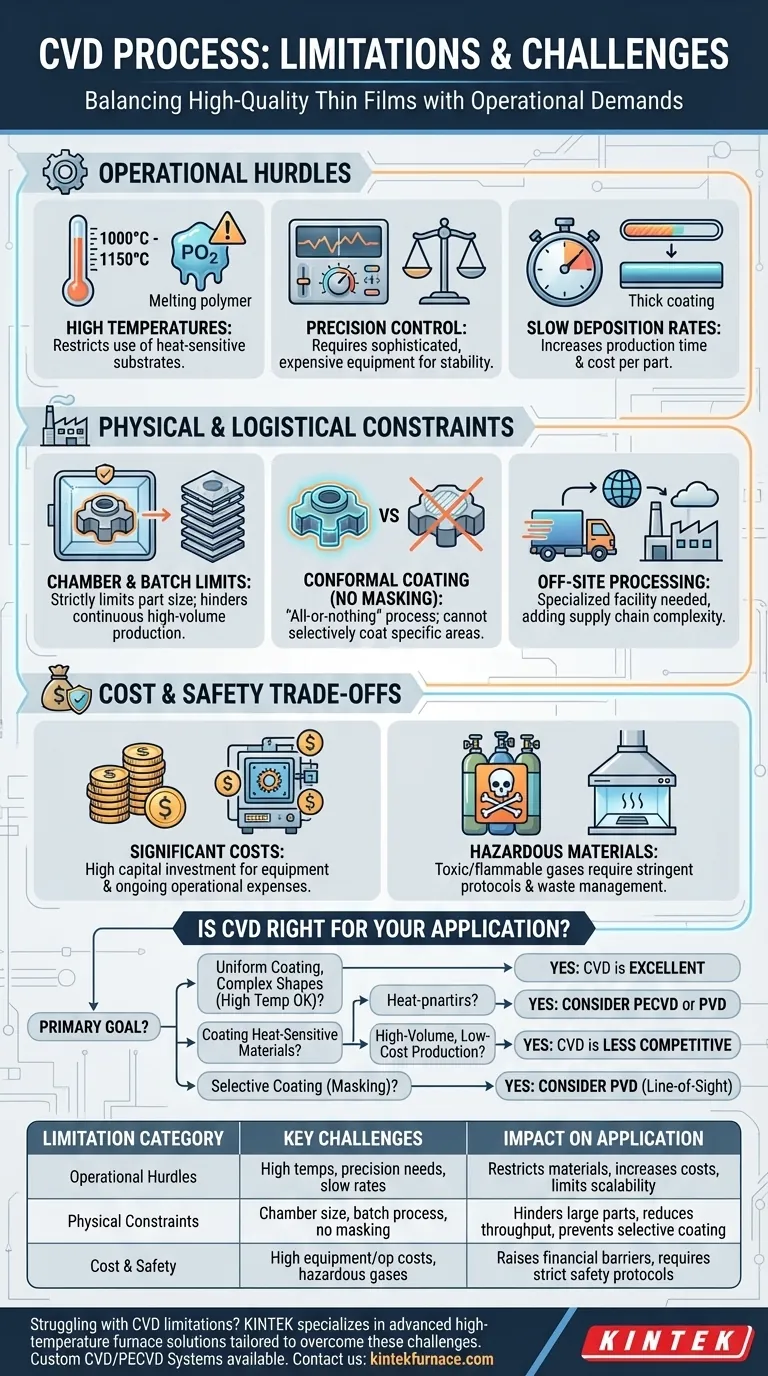

The Operational Hurdles of CVD

To understand the limitations of CVD, we must first look at the inherent demands of the process itself. These are not flaws, but fundamental characteristics that define its application window.

Demanding High-Temperature Environments

The chemical reactions at the heart of the CVD process often require significant thermal energy. Many CVD processes operate at temperatures between 1000°C and 1150°C.

This intense heat is a major constraint, as it prohibits the use of heat-sensitive substrates like polymers or certain metal alloys that would deform or melt.

The Need for Precision Control

The quality of a CVD film is directly tied to the stability of the reaction environment. Any deviation in process parameters can lead to defects in the final coating.

Factors like temperature, pressure, and gas flow rates must be controlled with extreme precision. Maintaining this stability is complex and requires sophisticated, and therefore expensive, equipment.

Slow Deposition Rates

Compared to other methods like Physical Vapor Deposition (PVD), the CVD process can be relatively slow.

This slower rate of film growth increases production time and, consequently, the overall cost per part, especially for thicker coatings.

The Physical and Logistical Constraints

Beyond the operational challenges, CVD faces physical limitations that affect its scalability and the types of parts it can accommodate.

Chamber Size and Batch Processing

Parts must be placed inside a sealed reaction chamber. The dimensions of this chamber strictly limit the maximum size of any component that can be coated.

Furthermore, this setup necessitates batch processing. This can increase lead times and makes it difficult to scale the process for high-volume, continuous mass production.

The "All-or-Nothing" Coating

CVD is a conformal coating process, meaning the precursor gases will react and deposit a film on every single exposed surface of the part.

It is not possible to mask specific areas to prevent them from being coated. If selective coating is required, CVD is often the wrong choice.

Off-Site Processing

CVD is a specialized, industrial process that cannot be performed in a typical manufacturing facility. Parts must be sent to a dedicated coating service provider, adding complexity and time to the supply chain.

Understanding the Trade-offs: Cost and Safety

The practical implementation of CVD involves significant financial and safety considerations that every team must weigh.

Significant Equipment and Operational Costs

The specialized equipment required for CVD—including the high-temperature furnace, vacuum systems, and gas handling controls—represents a substantial capital investment.

Operational costs are also high, driven by energy consumption, the price of high-purity precursor gases, and the need for skilled technicians to run and maintain the systems.

Handling Hazardous Materials

The precursor gases used in CVD are often toxic, flammable, or corrosive. This reality mandates stringent safety protocols and facility infrastructure to protect personnel.

Additionally, the chemical reactions generate hazardous byproducts that must be managed and disposed of properly. This requires effective exhaust scrubbing and waste management systems to ensure both operator safety and environmental compliance.

Is CVD the Right Choice for Your Application?

Choosing a coating technology requires aligning its capabilities and limitations with your primary goal.

- If your primary focus is a perfectly uniform coating on complex shapes: CVD is an excellent candidate, provided the substrate can withstand the high processing temperatures.

- If your primary focus is coating heat-sensitive materials: Traditional high-temperature CVD is unsuitable, and you should investigate alternatives like Plasma-Enhanced CVD (PECVD) or PVD.

- If your primary focus is high-volume, low-cost production: The batch nature, slow deposition rates, and high operational costs of CVD make it less competitive for this goal.

- If your primary focus is coating only a specific area of a part: CVD is a poor choice due to its inability to be masked; a line-of-sight process like PVD is a better fit.

Ultimately, selecting CVD is a decision that requires balancing its superior film quality against its significant operational, financial, and safety demands.

Summary Table:

| Limitation Category | Key Challenges | Impact on Application |

|---|---|---|

| Operational Hurdles | High temperatures (1000-1150°C), precision control needs, slow deposition rates | Restricts material compatibility, increases costs, limits scalability |

| Physical Constraints | Chamber size limits, batch processing, conformal coating (no masking) | Hinders large parts, reduces throughput, prevents selective coating |

| Cost and Safety | High equipment/operational costs, hazardous gases and byproducts | Raises financial barriers, requires strict safety protocols |

Struggling with CVD limitations for your lab? KINTEK specializes in advanced high-temperature furnace solutions tailored to overcome these challenges. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems with deep customization to meet your unique experimental needs. Enhance your coating processes with our reliable, safe, and cost-effective equipment. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations