The primary advantages of ceramic materials like alumina and silicon nitride in heating elements are their unique combination of high-temperature resistance, excellent electrical insulation, high thermal conductivity, and superior corrosion resistance. This set of properties allows them to operate more safely, efficiently, and for longer durations than traditional metal-sheathed heating elements, especially in demanding industrial environments.

The core value of ceramic heaters is their ability to resolve a fundamental conflict: they efficiently transfer heat while completely blocking electricity. This duality enables simpler, safer, and more durable heating element designs that are impossible to achieve with metals alone.

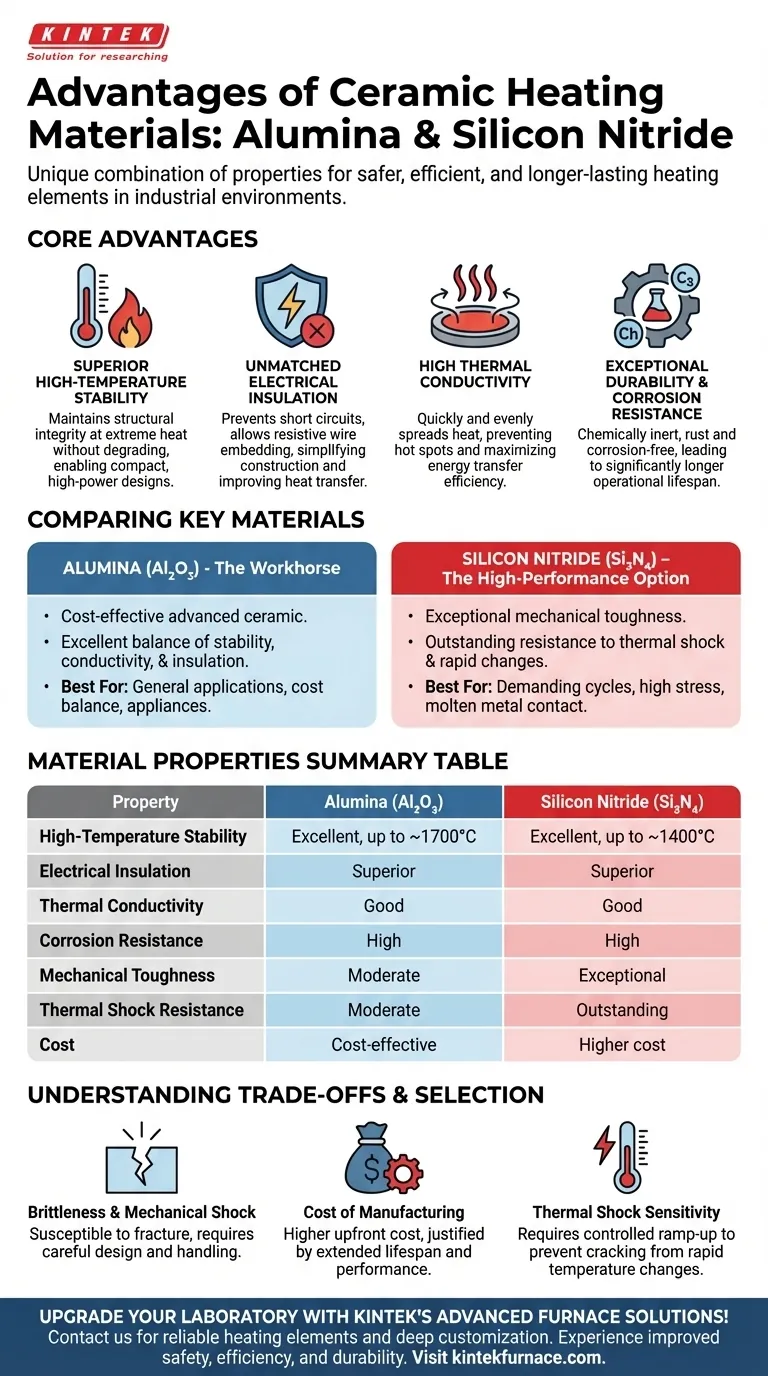

Deconstructing the Core Advantages

To truly understand the value of ceramics like alumina (Al₂O₃) and silicon nitride (Si₃N₄), we must look at how each core property translates into a tangible engineering benefit.

### Superior High-Temperature Stability

Ceramic materials are defined by their ability to withstand extreme heat without degrading. Unlike metals that can warp, soften, or melt, advanced ceramics maintain their structural integrity at very high operating temperatures.

This allows for the design of compact, high-power heaters that can operate reliably in environments where metals would quickly fail.

### Unmatched Electrical Insulation

This is perhaps the most critical safety and design advantage. Ceramics are excellent electrical insulators, preventing any risk of short circuits.

This property means the resistive heating wire can be embedded directly within or placed in direct contact with the ceramic body. This simplifies construction and improves thermal transfer, as no separate, bulky insulation layer is needed.

### High Thermal Conductivity

While being electrical insulators, these ceramics are also effective thermal conductors. This is the key to their efficiency.

High thermal conductivity ensures that heat generated by the internal resistive element is quickly and evenly spread across the heater's surface. This prevents destructive "hot spots" from forming on the element and transfers energy to the target with maximum efficiency.

### Exceptional Durability and Corrosion Resistance

Ceramics like alumina and silicon nitride are chemically inert. They do not rust or corrode, even when exposed to moisture or aggressive chemicals at high temperatures.

This inherent durability leads to a significantly longer operational lifespan compared to metal heaters, reducing maintenance cycles and replacement costs.

Comparing Key Ceramic Materials

While alumina and silicon nitride share these core benefits, they are not interchangeable. Each material has a distinct performance profile suited for different applications.

### Alumina (Al₂O₃): The Workhorse

Alumina is the most widely used and cost-effective advanced ceramic for heating applications. It provides an excellent all-around balance of high-temperature stability, good thermal conductivity, and superb electrical insulation.

It serves as the benchmark material for a vast range of applications, from heating tube fillers to consumer appliance elements.

### Silicon Nitride (Si₃N₄): The High-Performance Option

Silicon nitride stands out for its exceptional mechanical toughness and outstanding resistance to thermal shock—the ability to withstand rapid temperature changes without cracking.

These properties make it the ideal choice for demanding applications involving rapid heating cycles, high mechanical stress, or direct contact with molten metals.

### Other Advanced Ceramics (AlN, SiC)

For specialized needs, other ceramics offer even more extreme performance. Aluminum Nitride (AlN) provides exceptionally high thermal conductivity for applications requiring the fastest possible heating and perfect temperature uniformity.

Silicon Carbide (SiC) and Molybdenum Disilicide (MoSi₂) are used for ultra-high-temperature furnaces, capable of operating reliably at temperatures approaching 2000°C.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of ceramics is critical for successful implementation.

### Brittleness and Mechanical Shock

The primary drawback of ceramics is their brittleness. Unlike metals, which can bend or deform under stress, ceramics will fracture.

This requires careful design considerations for mounting, handling, and protecting the element from physical impact during its operational life.

### Cost of Manufacturing

The processes for creating and shaping high-purity ceramic components are more complex and energy-intensive than those for fabricating metal parts.

Consequently, advanced ceramic heating elements typically have a higher upfront cost, which is justified by their extended lifespan and superior performance.

### Thermal Shock Sensitivity

While materials like silicon nitride excel in this area, ceramics as a class can be susceptible to cracking if subjected to extremely rapid and non-uniform temperature changes.

Proper system control, such as programming a controlled ramp-up rate for the power supply, is often necessary to mitigate this risk and ensure long-term reliability.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the specific performance goals and operational environment of your project.

- If your primary focus is a balance of performance and cost for general applications: Alumina (Al₂O₃) is the industry standard, offering excellent all-around properties.

- If your primary focus is extreme durability and resistance to thermal shock: Silicon Nitride (Si₃N₄) provides superior mechanical strength and toughness for demanding cycles.

- If your primary focus is the fastest possible heating and uniform temperature: Aluminum Nitride (AlN) is the premier choice due to its exceptional thermal conductivity.

- If your primary focus is operating at the highest possible temperatures: Materials like Silicon Carbide (SiC) are engineered specifically for extreme thermal loads.

By understanding these material properties, you can select a ceramic heater that delivers not just heat, but also the precise performance, safety, and longevity your system requires.

Summary Table:

| Property | Alumina (Al₂O₃) | Silicon Nitride (Si₃N₄) |

|---|---|---|

| High-Temperature Stability | Excellent, up to ~1700°C | Excellent, up to ~1400°C |

| Electrical Insulation | Superior | Superior |

| Thermal Conductivity | Good | Good |

| Corrosion Resistance | High | High |

| Mechanical Toughness | Moderate | Exceptional |

| Thermal Shock Resistance | Moderate | Outstanding |

| Cost | Cost-effective | Higher cost |

| Best For | General applications, cost balance | Demanding cycles, high stress |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, enhanced by strong deep customization to meet unique experimental requirements. Experience improved safety, efficiency, and durability—contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance