The primary advantages of a dental lab furnace are its exceptional precision, material versatility, and operational efficiency. This critical piece of equipment uses highly accurate temperature control to melt, cast, and sinter materials like ceramics, alloys, and zirconia, ensuring the consistent production of high-quality dental restorations.

A modern dental furnace is more than a simple oven; it is the cornerstone of a high-performance dental laboratory. Its true value lies in empowering technicians to create durable, perfectly fitting restorations with speed and reliability, directly impacting both clinical outcomes and economic efficiency.

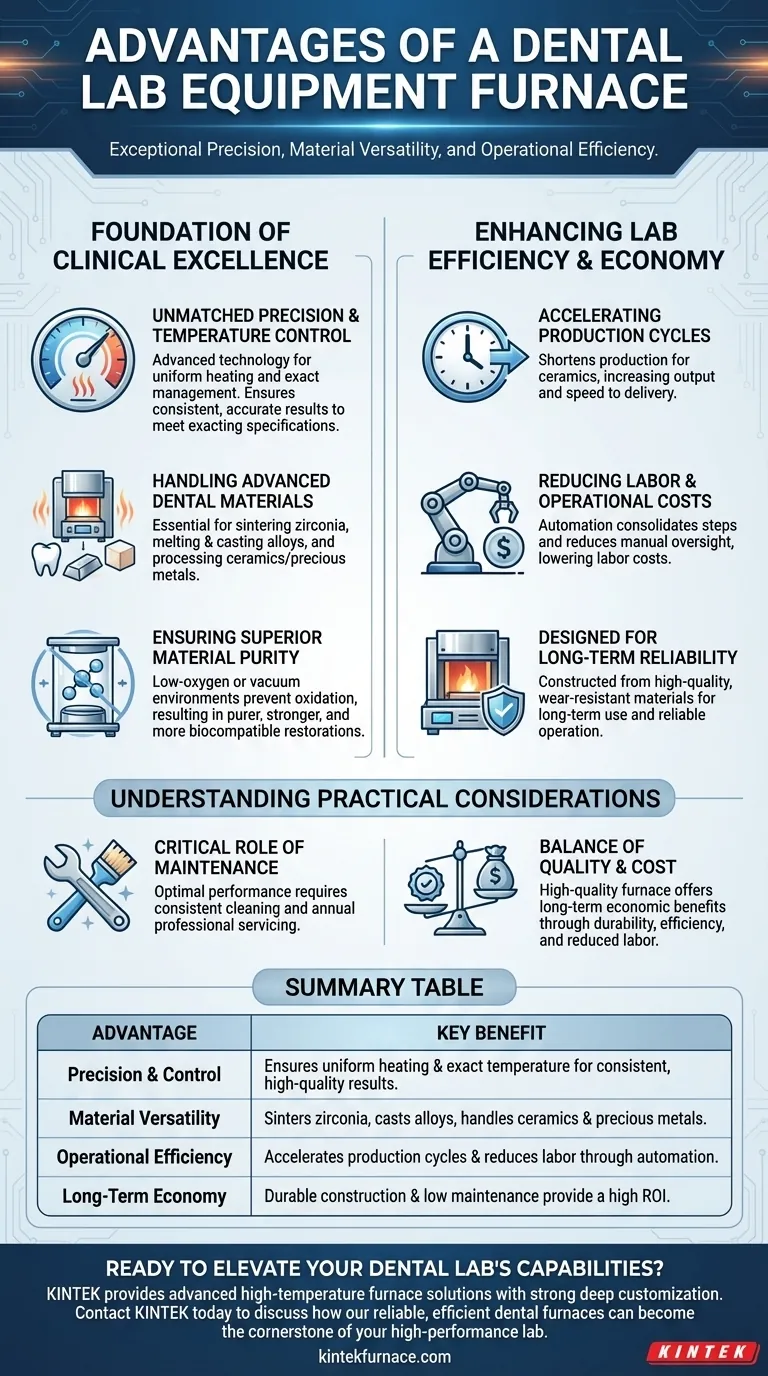

The Foundation of Clinical Excellence

A furnace's core function is to transform raw materials into finished dental products. Its ability to do this with precision is what separates acceptable results from exceptional ones.

Unmatched Precision and Temperature Control

The furnace’s advanced technology provides uniform heating and exact temperature management. This precision is critical for maintaining the structural integrity of the final product.

Consistent and accurate results are the standard, ensuring every crown, bridge, or implant meets exacting clinical specifications.

Handling Advanced Dental Materials

Modern dentistry relies on materials like zirconia, which require extremely high temperatures for the sintering process. A specialized furnace is essential for creating robust and aesthetically pleasing zirconia restorations.

It is also capable of melting and casting a wide range of other materials, including various alloys, ceramics, and even precious metals.

Ensuring Superior Material Purity

Many dental furnaces are designed to operate in low-oxygen or vacuum environments.

This capability is crucial for preventing oxidation, which can compromise the strength and biocompatibility of dental alloys and other sensitive materials. The result is a purer, more reliable restoration.

Enhancing Lab Efficiency and Economy

Beyond clinical quality, a dental furnace delivers significant operational benefits that directly impact a lab's bottom line.

Accelerating Production Cycles

Compared to traditional processing methods, a modern sintering furnace greatly shortens the production cycle for ceramic products.

This speed allows labs to increase their output and deliver finished restorations to clinicians and patients much faster.

Reducing Labor and Operational Costs

The automation and stability of a furnace consolidate process steps and reduce the need for constant manual oversight.

This efficiency translates directly into lower labor costs and makes the furnace an economical selection over its lifespan.

Designed for Long-Term Reliability

These furnaces are constructed from high-quality, wear-resistant materials.

The heating element is typically made of a durable material that can withstand high temperatures for extended periods, ensuring reliability and long-term use. Many are also designed for quiet operation, creating a better working environment.

Understanding the Practical Considerations

While the advantages are clear, maximizing the value of a dental furnace requires understanding its operational needs and long-term context.

The Critical Role of Maintenance

Optimal performance and longevity are not guaranteed. They depend on consistent, proper care.

Regularly cleaning the furnace and its components is essential for preventing malfunctions. It is highly recommended to have the furnace professionally serviced at least once a year to ensure its accuracy and safety.

The Balance of Quality and Cost

A high-quality furnace represents a significant initial investment. However, its durability, efficiency, and ability to reduce labor costs provide substantial long-term economic benefits.

Choosing a furnace is not just about the purchase price but its overall value in improving workflow and output quality.

Making the Right Choice for Your Lab

Selecting a furnace should be guided by the specific goals and workflow of your laboratory.

- If your primary focus is high-volume production: Prioritize a furnace with a large capacity, fast cycle times, and programmable settings to maximize throughput.

- If your primary focus is advanced cosmetic restorations: Seek a furnace with precise temperature control and specialized programs for materials like zirconia and lithium disilicate.

- If your primary focus is overall cost-effectiveness: Look for a durable, reliable model with a reputation for low maintenance and energy efficiency to ensure the best long-term return on investment.

Ultimately, the right dental furnace is a strategic asset that elevates a lab's technical capability and business potential.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision & Control | Ensures uniform heating and exact temperature for consistent, high-quality results. |

| Material Versatility | Sinters zirconia, casts alloys, and handles ceramics and precious metals. |

| Operational Efficiency | Accelerates production cycles and reduces labor through automation. |

| Long-Term Economy | Durable construction and low maintenance provide a high return on investment. |

Ready to Elevate Your Dental Lab's Capabilities?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique production requirements for zirconia sintering, alloy casting, and more.

Contact KINTEL today to discuss how our reliable, efficient dental furnaces can become the cornerstone of your high-performance lab, ensuring superior clinical outcomes and economic efficiency.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a vacuum porcelain furnace ensure the bonding quality? Achieve Superior Metal-Ceramic Restorations

- What should routine inspections of dental furnaces include? Ensure Consistent, High-Quality Dental Restorations

- What are some recent innovations in dental lab equipment furnaces? Boost Efficiency with Smart Automation

- What happens if the timing is incorrect during a dental furnace operation? Avoid Ruined Restorations

- What is the step-by-step process for making porcelain dental restorations? Master Precision and Aesthetics