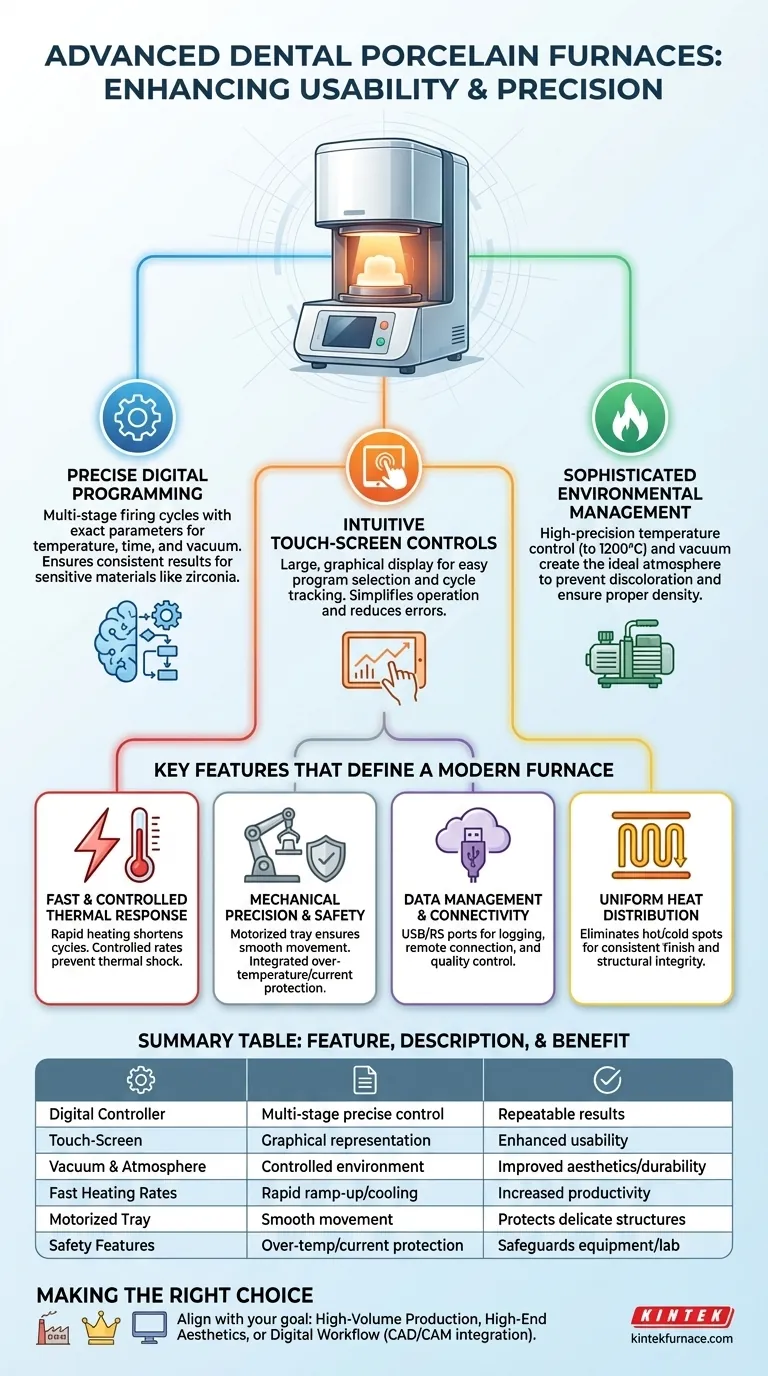

In short, advanced dental porcelain furnaces enhance usability through three primary advancements: precise digital programming, intuitive touch-screen controls, and sophisticated environmental management. These features work in concert to deliver repeatable, high-quality results for a wide range of modern dental materials, moving far beyond the capabilities of older, manually controlled ovens.

The core evolution of dental furnaces is the shift from being simple heating devices to becoming precision instruments for materials processing. The most valuable "advanced features" are those that give the technician granular, repeatable control over the entire firing cycle, ensuring the final restoration's integrity and aesthetics.

From Ovens to Precision Instruments

To understand the value of modern features, it's crucial to recognize that a dental furnace is not just an oven. Its job is to precisely control a material transformation process, such as sintering, where particles are fused together under heat to create a solid, durable restoration.

The Foundation: Programmable Firing Cycles

The single most important advancement is the digital programmable controller. This is the brain of the furnace, dictating every stage of the heating and cooling process.

Older furnaces required constant manual supervision. Modern furnaces allow technicians to define and save multi-stage programs with exact parameters for temperature, time, and vacuum.

This capability is the key to achieving consistent results with sensitive materials like lithium disilicate or zirconia.

The Interface: Intuitive Controls and Data Management

Usability is dramatically enhanced by how a technician interacts with the furnace. Modern designs prioritize clarity and ease of use.

A large, color touch-screen display is now standard. It provides a clear, graphical representation of the firing cycle, making it simple to select pre-set programs or create custom ones.

Furthermore, features like USB ports for data logging or RS 232/485 ports for remote connection allow for better quality control, record keeping, and troubleshooting.

Key Features That Define a Modern Furnace

Beyond the core controller, several features work together to ensure the process is executed flawlessly, directly impacting the quality of the final crown, bridge, or veneer.

Precision Heating and Atmosphere Control

The quality of the firing chamber is paramount. A furnace must create a perfectly controlled environment.

This is achieved through an efficient chamber design that ensures uniform heat distribution. This eliminates hot or cold spots that could cause stress, cracks, or an inconsistent finish in the ceramic.

High-precision temperature control, often accurate to a single degree up to 1200°C, combined with a powerful vacuum pump, allows the furnace to create the exact atmosphere required to prevent porcelain discoloration and ensure proper density.

Fast and Controlled Thermal Response

Modern furnaces feature fast heating rates. This capability can significantly shorten firing cycles, improving lab productivity.

However, the control over these rates is just as important. The ability to dictate a slow, steady ramp-up in temperature or a controlled cooling phase is critical for preventing thermal shock and ensuring the material's structural integrity.

Mechanical Precision and Safety

The physical movement of the restoration into and out of the hot zone is also a critical step.

A precise motorized tray ensures smooth, jerk-free movement. This prevents vibrations that could disturb carefully placed porcelain powders or damage delicate structures before they are fully sintered.

Integrated safety features, such as over-temperature and over-current protection, are essential for protecting the equipment, the restoration, and the lab environment.

Understanding the Trade-offs

While advanced features offer significant benefits, they require careful consideration.

Complexity vs. Control

A highly programmable furnace offers immense control but also comes with a steeper learning curve. A lab must be prepared to invest time in training to leverage these capabilities fully.

Material Compatibility Is Not Automatic

A furnace may be capable of firing dozens of materials, but it does not replace the technician's expertise. Understanding the specific requirements for each type of porcelain, zirconia, or composite is still the most critical factor for success. The furnace is a tool that executes the technician's expert instructions.

Cost vs. Required Capability

Not every lab needs a furnace with every possible feature. A small lab focused on a limited range of materials may not need the same level of programmability or data connectivity as a large, high-volume production center. The key is to match the investment to the workflow.

Making the Right Choice for Your Goal

Ultimately, the best furnace is the one that aligns with your lab's primary objectives.

- If your primary focus is high-volume production: Prioritize furnaces with fast heating rates, a large library of programmable cycles, and robust, reliable mechanics to maximize throughput.

- If your primary focus is high-end aesthetics: Invest in a furnace with exceptional temperature uniformity, precise vacuum control, and the ability to fine-tune every parameter of the firing cycle for custom shading and characterization.

- If your primary focus is a digital workflow (e.g., inLab/CEREC): Choose a furnace that offers certified programs and seamless integration with your CAD/CAM system to ensure predictable results for specific material blocks.

Choosing the right furnace is about empowering your skill and enabling you to produce the highest quality work consistently and efficiently.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Digital Programmable Controller | Allows multi-stage firing cycles with precise temperature, time, and vacuum control. | Ensures repeatable results for materials like lithium disilicate and zirconia. |

| Intuitive Touch-Screen Display | Provides graphical cycle representation and easy program selection. | Enhances usability and reduces errors in operation. |

| Vacuum and Atmosphere Control | Uses vacuum pumps and uniform heating to prevent discoloration and ensure material density. | Improves restoration aesthetics and durability. |

| Fast Heating Rates | Enables rapid temperature increases with controlled ramp-up and cooling. | Increases lab productivity while preventing thermal shock. |

| Motorized Tray System | Ensures smooth, vibration-free movement of restorations. | Protects delicate structures during firing. |

| Safety Features | Includes over-temperature and over-current protection. | Safeguards equipment, restorations, and lab environment. |

Ready to elevate your dental lab's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Whether you're focused on high-volume production, high-end aesthetics, or digital workflows, our furnaces deliver precise control and reliability. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations