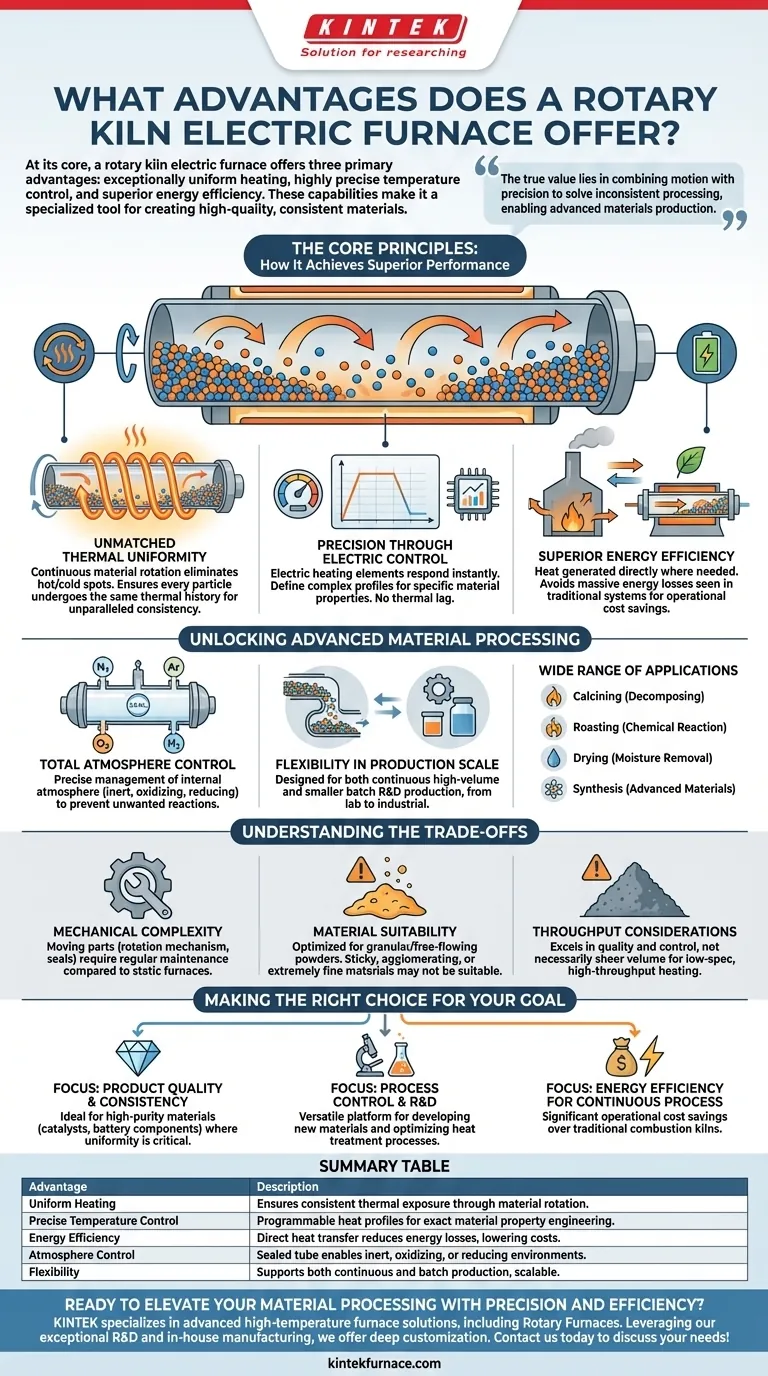

At its core, a rotary kiln electric furnace offers three primary advantages: exceptionally uniform heating due to material rotation, highly precise temperature control from its electric source, and superior energy efficiency compared to combustion-based systems. These capabilities make it a specialized tool for creating high-quality, consistent materials.

The true value of a rotary electric furnace lies in its ability to combine motion with precision. By continuously tumbling materials through a tightly controlled thermal and atmospheric environment, it solves the challenge of inconsistent processing, enabling the production of advanced materials that are impossible to achieve in standard static furnaces.

The Core Principles: How It Achieves Superior Performance

A rotary electric furnace is not just a heated tube; it is an integrated system where each component contributes to a highly controlled processing environment.

Unmatched Thermal Uniformity

The defining feature is the rotation of the furnace tube. As the tube spins, the material inside gently tumbles, continuously exposing new surfaces to the heat source.

This constant mixing eliminates hot and cold spots that plague static furnaces, ensuring every particle undergoes the same thermal history. The result is unparalleled consistency in the final product.

Precision Through Electric Control

Unlike fuel-fired furnaces, which have thermal lag, electric heating elements respond almost instantly. This allows for precise, programmable control over the entire heat treatment cycle.

Users can define complex profiles with specific ramp rates, soak times, and cooling curves. This level of control is critical for engineering specific material properties, such as crystallinity or particle size.

Superior Energy Efficiency

Electric rotary kilns are inherently more efficient. Heat is generated directly where it is needed, within the furnace walls, and transferred efficiently to the tumbling material.

This design avoids the massive energy losses seen in traditional furnaces, where energy is wasted heating the furnace structure, exhaust gases, and transport carts.

Unlocking Advanced Material Processing

The combination of uniform heating and precise control opens the door to a wide range of sensitive applications where product quality is paramount.

Total Atmosphere Control

Because the material is contained within a sealed tube, the internal atmosphere can be precisely managed. The furnace can operate with an inert (e.g., Nitrogen, Argon), oxidizing (e.g., Air, Oxygen), or reducing (e.g., Hydrogen) atmosphere.

This prevents unwanted chemical reactions, such as oxidation, which is critical for processing high-purity metals, battery materials like lithium-ion cathodes, and sensitive catalysts.

Flexibility in Production Scale

These furnaces are designed for both continuous and batch production. A continuous flow of material can be fed for high-volume manufacturing, while smaller, distinct quantities can be processed for research and development.

This adaptability allows a single unit to serve functions from initial lab-scale testing to full-scale industrial production, providing a strong return on investment.

Wide Range of Applications

The unique capabilities of the rotary electric furnace make it indispensable for several key processes:

- Calcining: Thermally decomposing materials to create new phases.

- Roasting: Heating solids to induce a specific chemical reaction.

- Drying: Removing moisture with precise temperature control.

- Synthesis: Creating advanced materials like battery components and catalysts.

Understanding the Trade-offs

While powerful, this technology is not a universal solution. Understanding its limitations is key to making an informed decision.

Mechanical Complexity

The rotation mechanism, including the support rollers, drive gear, and seals, introduces moving parts. Compared to a simple static box furnace, these components require regular inspection and maintenance to ensure reliable, long-term operation.

Material Suitability

The design is optimized for granular or free-flowing powdered materials. Materials that are very sticky, prone to agglomeration, or extremely fine (which can become airborne) may not be suitable for a tumbling process and could require specialized furnace designs.

Throughput Considerations

For simple, high-volume heating of non-sensitive bulk materials, a larger, less complex belt or static furnace may offer higher raw throughput. The rotary electric furnace excels in quality and control, not necessarily in sheer volume for low-spec applications.

Making the Right Choice for Your Goal

To determine if this furnace is the correct tool, evaluate your primary objective.

- If your primary focus is product quality and consistency: This furnace is the ideal choice for creating high-purity materials like catalysts or battery components where uniformity is non-negotiable.

- If your primary focus is process control and R&D: The ability to precisely manage temperature and atmosphere makes it a versatile platform for developing new materials and optimizing heat treatment processes.

- If your primary focus is energy efficiency for a continuous process: This furnace offers significant operational cost savings over traditional combustion kilns by minimizing wasted heat.

Ultimately, the rotary electric furnace empowers you to transform materials with a level of control that directly translates to superior performance and value.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Ensures consistent thermal exposure through material rotation, eliminating hot/cold spots. |

| Precise Temperature Control | Electric elements allow programmable heat profiles for exact material property engineering. |

| Energy Efficiency | Direct heat transfer reduces energy losses, lowering operational costs. |

| Atmosphere Control | Sealed tube enables inert, oxidizing, or reducing environments for high-purity processing. |

| Flexibility | Supports both continuous and batch production, scalable from R&D to industrial use. |

Ready to elevate your material processing with precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Rotary Furnaces, designed for labs and industries requiring uniform heating and exact control. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance your product quality and reduce costs!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity