Beyond simply reaching high temperatures, a laboratory vacuum furnace offers a suite of advanced capabilities centered on creating a highly controlled, repeatable, and pure processing environment. These furnaces provide precise automation of the entire thermal cycle, fine-tuned atmospheric control, and integrated systems for process monitoring and safety, transforming them from a simple heater into a sophisticated instrument for materials research and development.

A laboratory vacuum furnace should be understood not as a tool for heat, but as a tool for control. Its primary function is to eliminate atmospheric variables and automate complex thermal processes, enabling the precise manipulation of material properties in an oxygen-free environment.

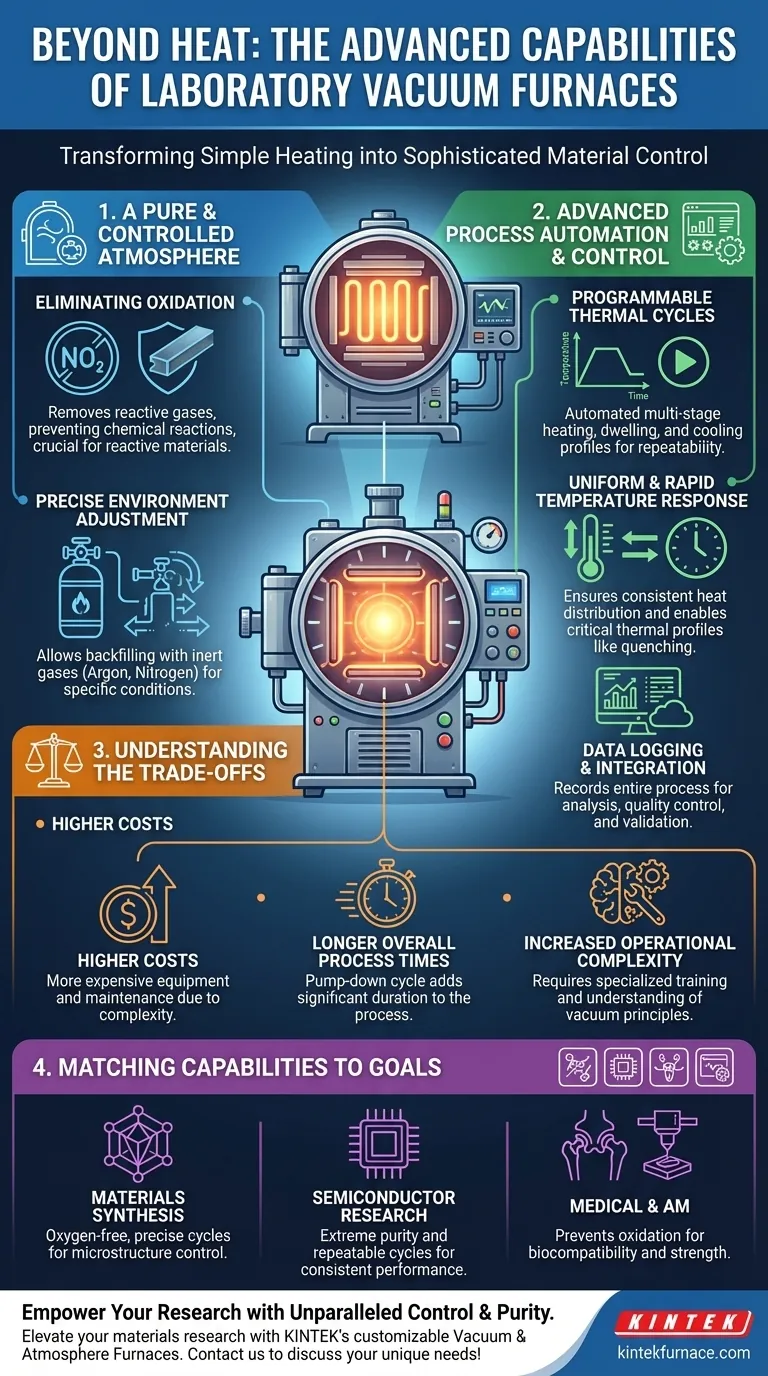

The Core Capability: A Pure and Controlled Atmosphere

The defining feature of a vacuum furnace is its ability to remove the atmosphere—and its contaminants—from the equation. This unlocks processing capabilities that are impossible in a standard furnace.

Eliminating Oxidation and Contamination

By pumping down the chamber to a vacuum, nearly all oxygen and other reactive gases are removed. This prevents oxidation and other unwanted chemical reactions that would otherwise occur at high temperatures.

This oxygen-free environment is critical for processing reactive metals, certain ceramics, and other sensitive materials, ensuring their chemical purity and structural integrity.

Adjusting the Environment with Precision

Modern vacuum furnaces allow for precise vacuum degree adjustment and can be backfilled with specific inert gases like argon or nitrogen. This gives you direct control over the exact atmospheric conditions of your process.

Researchers can study how materials behave under specific partial pressures or in completely inert environments, enabling the development of advanced materials with unique properties.

Advanced Process Automation and Control

Laboratory vacuum furnaces are defined by their ability to execute complex processes with exceptional accuracy and repeatability, thanks to sophisticated control systems.

Programmable Thermal Cycles

Most units feature programmable logic controllers (PLCs) or PID systems that automate the entire thermal profile. You can program multiple stages of heating ramps, dwell times at specific temperatures, and controlled cooling rates.

This automation ensures that every cycle is identical, which is essential for achieving repeatable experimental results and consistent material properties in small-scale production.

Uniform and Rapid Temperature Response

These furnaces use carefully engineered insulated heating zones and multiple temperature sensors to ensure uniform heat distribution across the entire workspace. This eliminates hot or cold spots that could ruin a sample.

They are also designed for rapid heating and cooling, which not only shortens process times but also enables thermal profiles, like quenching, that are critical for controlling a material's final microstructure.

Data Logging and System Integration

Many furnaces offer PC integration for remote control and, more importantly, comprehensive data logging. The system can record temperature, pressure, and gas flow throughout the entire process.

This data is invaluable for process analysis, quality control, and validating experimental results for publication or certification. Safety features like over-temperature protection and auto-shutdown are also standard.

Understanding the Trade-offs

While powerful, the capabilities of a vacuum furnace come with specific operational considerations. Understanding these is key to justifying its use.

Higher Equipment and Maintenance Costs

The complexity of the vacuum pumps, seals, chamber, and control systems makes these furnaces significantly more expensive than their atmospheric counterparts. Maintenance is also more involved, requiring regular checks of seals and vacuum system performance.

Longer Overall Process Times

While heating and cooling can be rapid, achieving a high vacuum takes time. The pump-down cycle can add a significant duration to the overall process, especially for larger chambers or when high vacuum levels are required.

Increased Operational Complexity

Operating a vacuum furnace requires more training and care than a standard furnace. Users must understand vacuum principles, leak detection, and proper loading procedures to ensure both safety and process success.

Matching Capabilities to Your Research Goal

To make the right choice, align the furnace’s capabilities with your specific application.

- If your primary focus is materials synthesis (e.g., advanced ceramics, composites): The ability to create an oxygen-free environment and execute precise, multi-stage thermal cycles is the most critical capability for controlling final microstructure and phase.

- If your primary focus is semiconductor research (e.g., annealing, diffusion): The key benefits are the extreme purity of the vacuum environment and the absolute repeatability of thermal cycles, ensuring consistent device performance.

- If your primary focus is medical devices or additive manufacturing (e.g., sintering implants, post-processing 3D-printed metal): The vacuum's prevention of oxidation is paramount for ensuring the biocompatibility, strength, and integrity of the final part.

Ultimately, these integrated capabilities empower you to move beyond simple heating and begin actively engineering material properties with unparalleled control.

Summary Table:

| Capability | Key Features | Benefits |

|---|---|---|

| Pure Atmosphere | Vacuum removal of oxygen, inert gas backfilling | Prevents oxidation, enables processing of reactive materials |

| Process Automation | Programmable thermal cycles, uniform heating, rapid response | Ensures repeatability, controls microstructure, reduces process times |

| Data and Safety | Data logging, PC integration, over-temperature protection | Supports analysis, quality control, and safe operation |

Ready to elevate your materials research with precision and control? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, designed for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance your processes and deliver reliable, repeatable results!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis