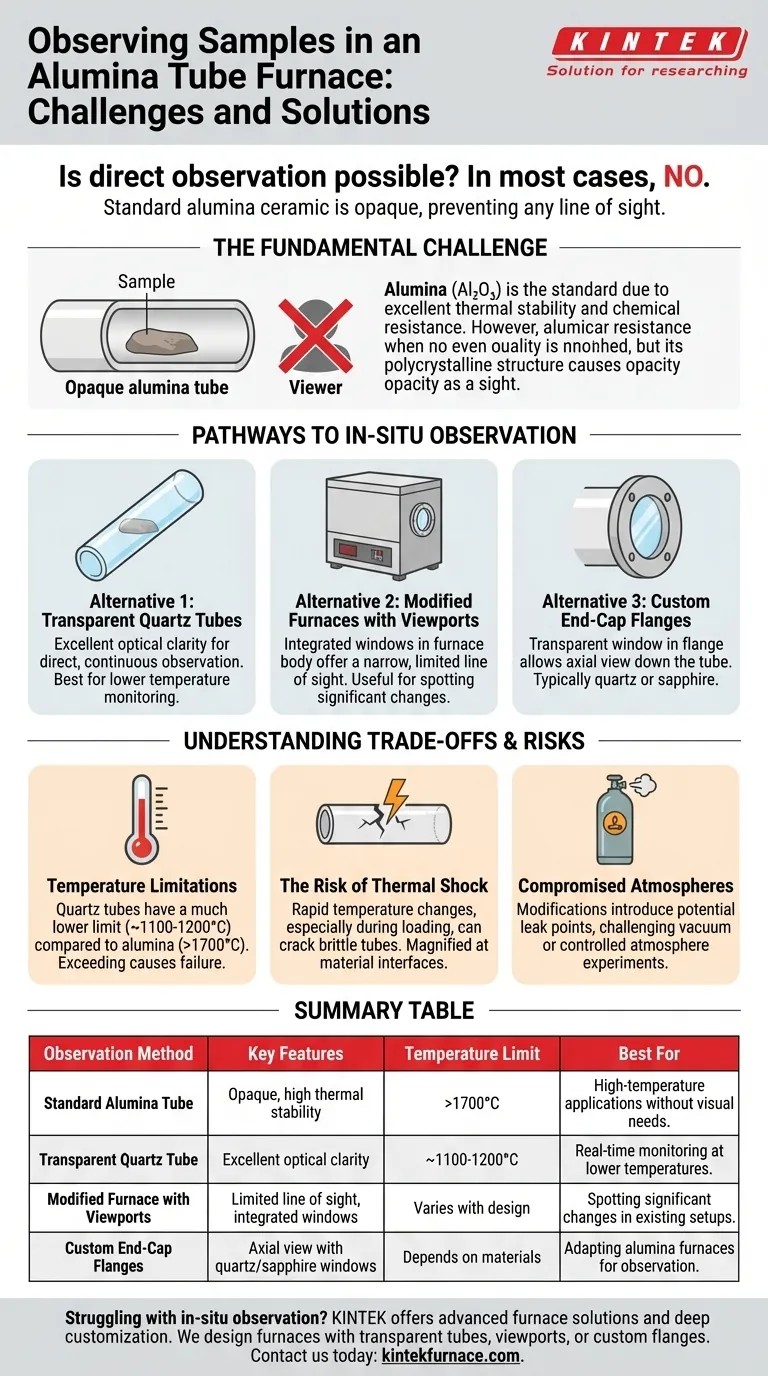

In most cases, direct observation of samples inside a standard alumina tube furnace is not possible. The high-purity alumina ceramic used for these tubes is opaque, preventing any line of sight to the sample during operation. However, specialized configurations and alternative materials exist specifically to solve this problem.

While the opacity of standard alumina tubes presents a fundamental barrier to observation, your need for in-situ monitoring is a common challenge in materials science. The solution lies not in a standard furnace, but in understanding the trade-offs between temperature limits and optical transparency.

The Fundamental Challenge: Material Properties

To understand why observation is an issue, we must first look at the material at the heart of the furnace.

Why Alumina is the Standard

Alumina (Aluminum Oxide, Al₂O₃) is the default choice for high-temperature tube furnaces due to its exceptional properties. It offers excellent thermal stability, remaining rigid and inert at temperatures exceeding 1700°C, and is highly resistant to chemical corrosion.

The Inherent Limitation: Opacity

The trade-off for this high performance is a lack of transparency. The polycrystalline structure of the ceramic scatters light, making the material opaque. You simply cannot see through a standard alumina furnace tube.

Pathways to In-Situ Observation

While a standard setup prohibits viewing, several well-established solutions enable real-time monitoring.

Alternative 1: Transparent Quartz Tubes

For many applications, the most straightforward solution is to use a furnace with a transparent quartz tube instead of an alumina one. Quartz provides excellent optical clarity, allowing for direct, continuous observation of the entire sample.

Alternative 2: Modified Furnaces with Viewports

Some furnace models are designed with integrated "viewports." These are small, high-temperature-rated windows built into the side of the furnace insulation and body, allowing a narrow line of sight to the tube's interior. This is a compromise, as the view is limited and the tube itself is still opaque, but it can be useful for spotting glowing, melting, or other significant changes.

Alternative 3: Custom End-Cap Flanges

A common modification involves integrating a transparent window directly into the end caps or flanges that seal the furnace tube. This allows for an axial view down the length of the tube. This window is typically made of quartz or, for more demanding applications, sapphire.

Understanding the Trade-offs and Risks

Choosing a method for observation requires balancing your goals against critical engineering limitations.

Temperature Limitations of Transparent Materials

This is the most significant trade-off. Quartz tubes have a much lower maximum operating temperature than alumina, typically around 1100-1200°C. Pushing a quartz tube beyond this limit will cause it to soften, deform, and fail.

The Risk of Thermal Shock

Ceramic and quartz tubes are brittle and highly susceptible to thermal shock—stress caused by rapid temperature changes. Loading or unloading a sample at high temperatures can easily crack the tube. This risk is magnified at the interface of different materials, such as where a quartz viewport is sealed to a metal furnace body.

Compromised Atmospheres

Any modification, such as a viewport or a custom flange, introduces a new potential leak point. For experiments requiring a high vacuum or a tightly controlled inert gas atmosphere, maintaining the integrity of these seals is a critical challenge.

Making the Right Choice for Your Goal

Your experimental requirements will dictate the best path forward.

- If your primary focus is reaching the highest possible temperatures (>1200°C): You must use an alumina tube, and direct visual observation will require highly specialized and often custom-built equipment with limited viewing angles.

- If your primary focus is clear, real-time visual monitoring below 1100°C: A furnace with a transparent quartz tube is the most effective and direct solution.

- If you need to adapt an existing alumina furnace for limited observation: Investigating custom end-cap flanges with integrated quartz or sapphire viewports is your most practical option.

By matching the observation method to your specific thermal and atmospheric requirements, you can gain the critical process insights you need.

Summary Table:

| Observation Method | Key Features | Temperature Limit | Best For |

|---|---|---|---|

| Standard Alumina Tube | Opaque, high thermal stability | >1700°C | High-temperature applications without visual needs |

| Transparent Quartz Tube | Excellent optical clarity | ~1100-1200°C | Real-time monitoring at lower temperatures |

| Modified Furnace with Viewports | Limited line of sight, integrated windows | Varies with design | Spotting significant changes in existing setups |

| Custom End-Cap Flanges | Axial view with quartz/sapphire windows | Depends on materials | Adapting alumina furnaces for observation |

Struggling with in-situ observation in your high-temperature experiments? KINTEK specializes in advanced furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we can design furnaces with transparent quartz tubes, integrated viewports, or custom flanges to enable precise sample monitoring while maintaining thermal and atmospheric control. Enhance your lab's efficiency and accuracy—contact us today to discuss how we can solve your observation challenges!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety