At its core, an electric rotary kiln is more environmentally friendly because it eliminates direct, on-site fossil fuel combustion. This means it produces zero sulfur dioxide (SO2) emissions at the point of operation and removes the logistical and safety challenges associated with storing and transporting fuel.

The key environmental advantage of an electric rotary kiln is its ability to decouple the industrial process from direct emissions. This shifts the environmental impact from the facility to the source of power generation, creating a pathway to a truly zero-emission operation when paired with renewable energy.

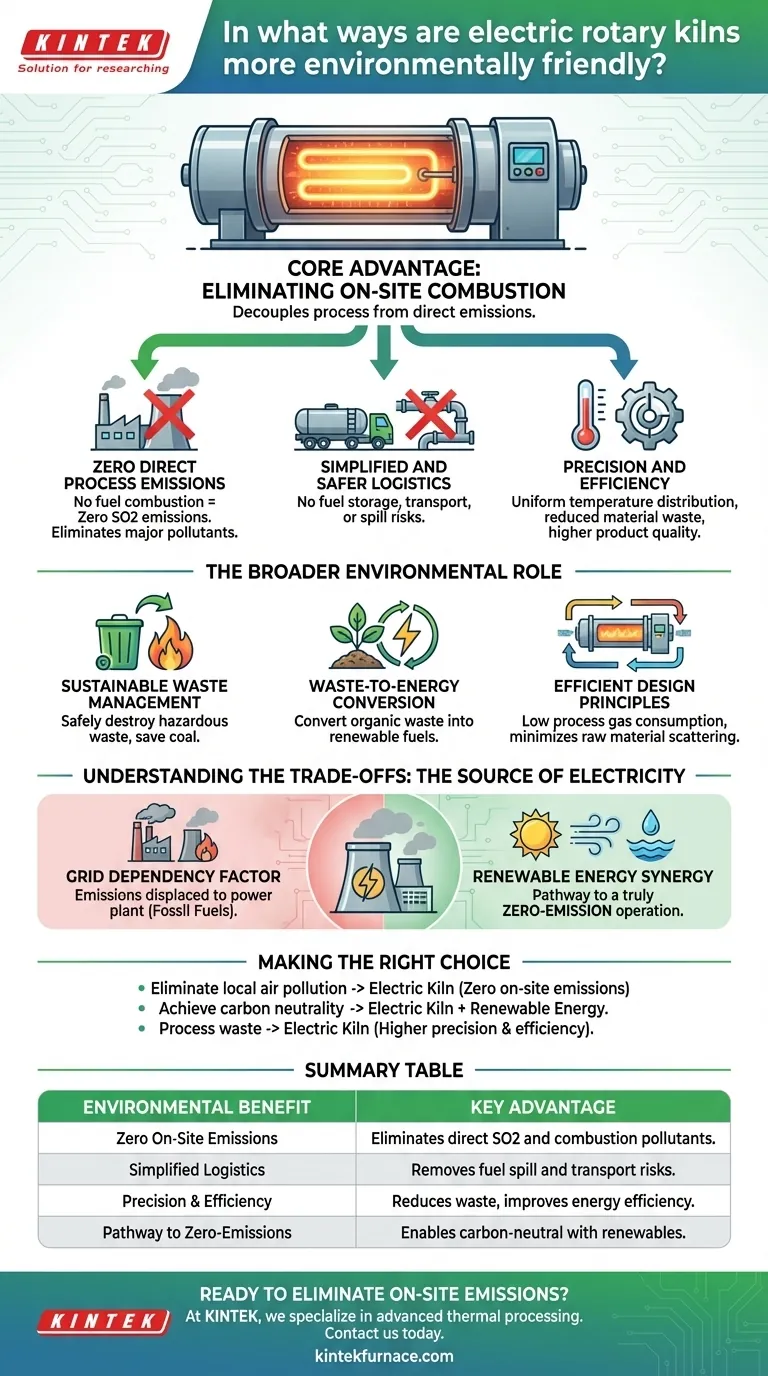

The Core Advantage: Eliminating On-Site Combustion

The primary environmental benefits of electric rotary kilns stem directly from their power source. By replacing traditional burners with electric heating elements, they fundamentally change the emissions profile and operational footprint of the facility.

Zero Direct Process Emissions

Because no fuel is burned to generate heat, electric kilns do not produce combustion byproducts. This completely eliminates the release of sulfur dioxide (SO2), a major pollutant that contributes to acid rain and can corrode the kiln's structure.

Simplified and Safer Logistics

Electric kilns do not require fuel storage tanks, pipelines, or transportation. This removes the environmental risks associated with potential fuel spills and eliminates the carbon footprint of trucks or trains delivering fuel to the site.

Precision and Efficiency

Electric heating provides extremely uniform temperature distribution and precise control. This consistency ensures higher product quality, reduces material waste, and can lead to more energy-efficient processes overall.

The Broader Environmental Role of Rotary Kilns

Beyond the specific benefits of electric models, rotary kiln technology in general plays a significant role in sustainable industrial practices. These advantages are shared by both electric and fuel-fired kilns.

Sustainable Waste Management

For decades, cement kilns have been used to safely destroy hazardous waste. The extremely high temperatures break down harmful compounds while using the waste itself as a supplemental fuel source, saving coal and recycling materials.

Waste-to-Energy Conversion

Indirect fired rotary kilns are critical in the renewable energy sector. They are used for processes like biomass gasification and pyrolysis, which convert organic waste into syngas, biochar, or renewable fuels.

Efficient Design Principles

Modern rotary kilns are designed to be environmentally conscious. Key features include low consumption of process gas and built-in measures that prevent the scattering of raw materials, minimizing waste and operational impact.

Understanding the Trade-offs: The Source of the Electricity

An electric kiln's environmental friendliness is not absolute. Its true impact is entirely dependent on the carbon intensity of the electrical grid that powers it.

The Grid Dependency Factor

If the electricity is generated by burning fossil fuels like coal or natural gas, the emissions are not eliminated—they are simply displaced from the kiln site to the power plant. The overall environmental benefit is significantly reduced in this scenario.

The Renewable Energy Synergy

The ultimate environmental advantage is realized when an electric kiln is powered by renewable sources like solar, wind, or hydropower. This combination creates a truly zero-emission thermal process, from start to finish.

Making the Right Choice for Your Goal

Evaluating whether an electric kiln is the right choice depends entirely on your primary environmental and operational objectives.

- If your primary focus is eliminating local air pollution: An electric kiln is the definitive choice, as it guarantees zero on-site process emissions.

- If your primary focus is achieving true carbon neutrality: An electric kiln is only the correct path if you have access to a verified renewable energy source.

- If your primary focus is processing waste materials: Both electric and fuel-fired kilns are highly effective, but an electric model offers more precise temperature control, potentially improving efficiency and output quality.

Ultimately, adopting an electric rotary kiln is a powerful step towards cleaner industry, but its full potential is only unlocked when it is part of a comprehensive clean energy strategy.

Summary Table:

| Environmental Benefit | Key Advantage |

|---|---|

| Zero On-Site Emissions | Eliminates direct SO2 and other combustion pollutants at the facility. |

| Simplified Logistics | Removes risks of fuel spills and transport-related emissions. |

| Precision & Efficiency | Uniform heating reduces waste and improves energy efficiency. |

| Pathway to Zero-Emissions | Enables carbon-neutral processing when paired with renewable energy. |

Ready to eliminate on-site emissions and enhance your process sustainability?

At KINTEK, we specialize in advanced thermal processing solutions. Our expertise in electric heating technology can help you achieve precise temperature control, superior product quality, and a significantly reduced environmental footprint. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for unique needs.

Contact us today to discuss how an electric rotary kiln can be integrated into your clean energy strategy. Let's build a greener future for your industry together. Get in touch now!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency