In practice, a quality porcelain furnace can last 20 to 25 years. With a commitment to proper maintenance and the occasional replacement of key wear components, it is not uncommon for labs to have furnaces from reputable manufacturers that are still performing reliably after two decades of service.

The question isn't just how long a furnace can last, but how long it can operate with the consistency and reliability your lab requires. Lifespan is a function of initial build quality, diligent maintenance, and a clear understanding of when to repair versus when to replace.

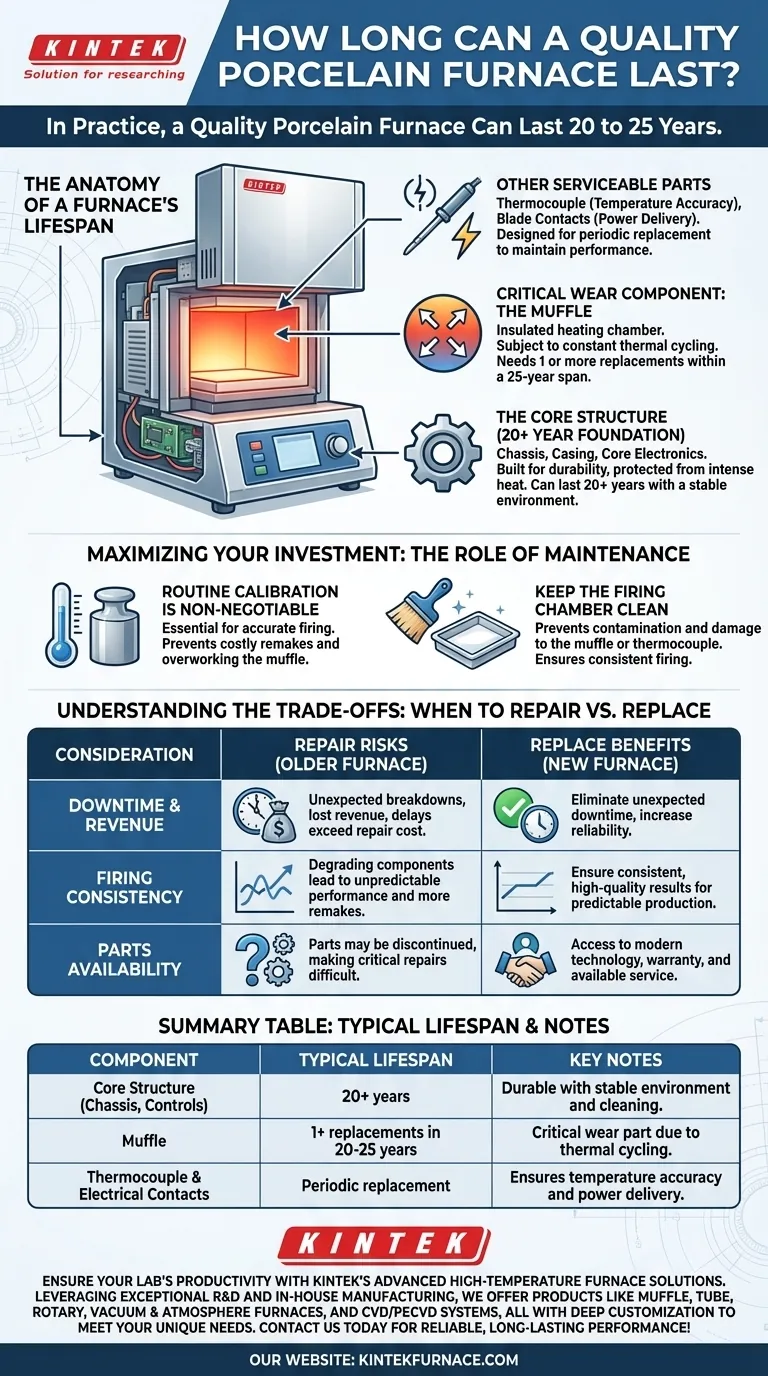

The Anatomy of a Furnace's Lifespan

A furnace's longevity is determined by the durability of its various parts. Some components are designed to last for decades, while others are considered consumables with a much shorter, predictable service life.

The Core Structure: The 20+ Year Foundation

The chassis, casing, and core electronic control boards of a high-quality furnace are built for extreme durability. These components are generally well-protected and not subject to the intense physical stresses of the firing process.

As long as the unit is kept clean and operated in a stable environment, this foundational structure can easily last more than 20 years.

Critical Wear Component: The Muffle

The muffle is the insulated heating chamber at the heart of the furnace. It contains the heating elements that generate the extreme temperatures required for firing porcelain.

Due to constant thermal cycling—expanding when hot and contracting when cool—the muffle is the single most significant wear component. While the furnace itself may last 25 years, a muffle will typically need to be replaced one or more times during that period.

Other Serviceable Parts

Other components are designed for periodic replacement to maintain performance. These include the thermocouple, which measures temperature and ensures firing accuracy, and electrical contacts like blade contacts, which can wear down over time and affect power delivery to the heating elements.

Maximizing Your Investment: The Role of Maintenance

Proactive maintenance is the single most important factor in extending the reliable life of your furnace and ensuring consistent, high-quality results.

Routine Calibration is Non-Negotiable

A furnace can only fire accurately if it knows the correct temperature. Regular calibration using silver or other calibration kits is essential.

This not only prevents costly remakes due to poor firing but also protects the muffle from being overworked or subjected to temperatures beyond its intended range.

Keep the Firing Chamber Clean

Debris or investment material left on the firing tray can contaminate restorations and, in some cases, damage the muffle or thermocouple.

Maintaining a clean chamber is a simple step that prevents a host of potential problems and ensures pure, consistent firing conditions.

Understanding the Trade-offs: When to Repair vs. Replace

An older furnace may still "work," but that doesn't always mean it's the right tool for the job. Knowing when to retire a unit is a critical business decision.

The True Cost of Downtime

As a furnace ages, the risk of an unexpected breakdown increases. While replacing a muffle may seem cost-effective, the lost revenue and production delays caused by unplanned downtime can far exceed the cost of the repair itself.

The Decline of Firing Consistency

Even with calibration, an aging furnace can struggle to maintain perfectly stable and even temperatures. Its components degrade, and its performance can become less predictable.

This can lead to subtle inconsistencies in shade, translucency, or fit, resulting in an increase in frustrating and expensive remakes.

Parts Availability and Service

For a furnace that is 20 or 25 years old, finding replacement parts can become a challenge. Manufacturers eventually discontinue support for older models, making a critical repair difficult or impossible.

Making the Right Choice for Your Lab

Your decision to maintain or replace a furnace should be guided by your lab's specific operational needs and goals.

- If your primary focus is maximizing the life of a current furnace: Commit to a strict schedule of calibration, cleaning, and proactive replacement of wear parts like the muffle and thermocouple.

- If your primary focus is predictable, high-volume production: Consider proactively replacing a furnace that is over 15 years old to eliminate the risk of unexpected downtime and declining consistency.

- If your primary focus is purchasing a new furnace: Look beyond the initial price and prioritize manufacturers with a proven reputation for long-term reliability and excellent parts and service availability.

Ultimately, a furnace's lifespan is a direct reflection of the quality of its construction and the diligence of its care.

Summary Table:

| Component | Typical Lifespan | Key Notes |

|---|---|---|

| Core Structure (Chassis, Controls) | 20+ years | Durable with stable environment and cleaning |

| Muffle | 1+ replacements in 20-25 years | Critical wear part due to thermal cycling |

| Thermocouple & Electrical Contacts | Periodic replacement | Ensures temperature accuracy and power delivery |

Ensure your lab's productivity with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today for reliable, long-lasting performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures