In the active sulfur coating process, the muffle furnace serves as a precision heating environment designed to bring a mixture of catalyst and sulfur to exactly 155 °C. This specific thermal threshold is critical because it transitions sulfur into a molten state, enabling it to physically infuse into the catalyst's structure rather than merely sitting on the surface.

By maintaining a controlled temperature of 155 °C, the furnace allows liquid sulfur to utilize capillary action to deeply infiltrate the catalyst's micropores, creating a fully integrated composite that is resistant to volume expansion issues.

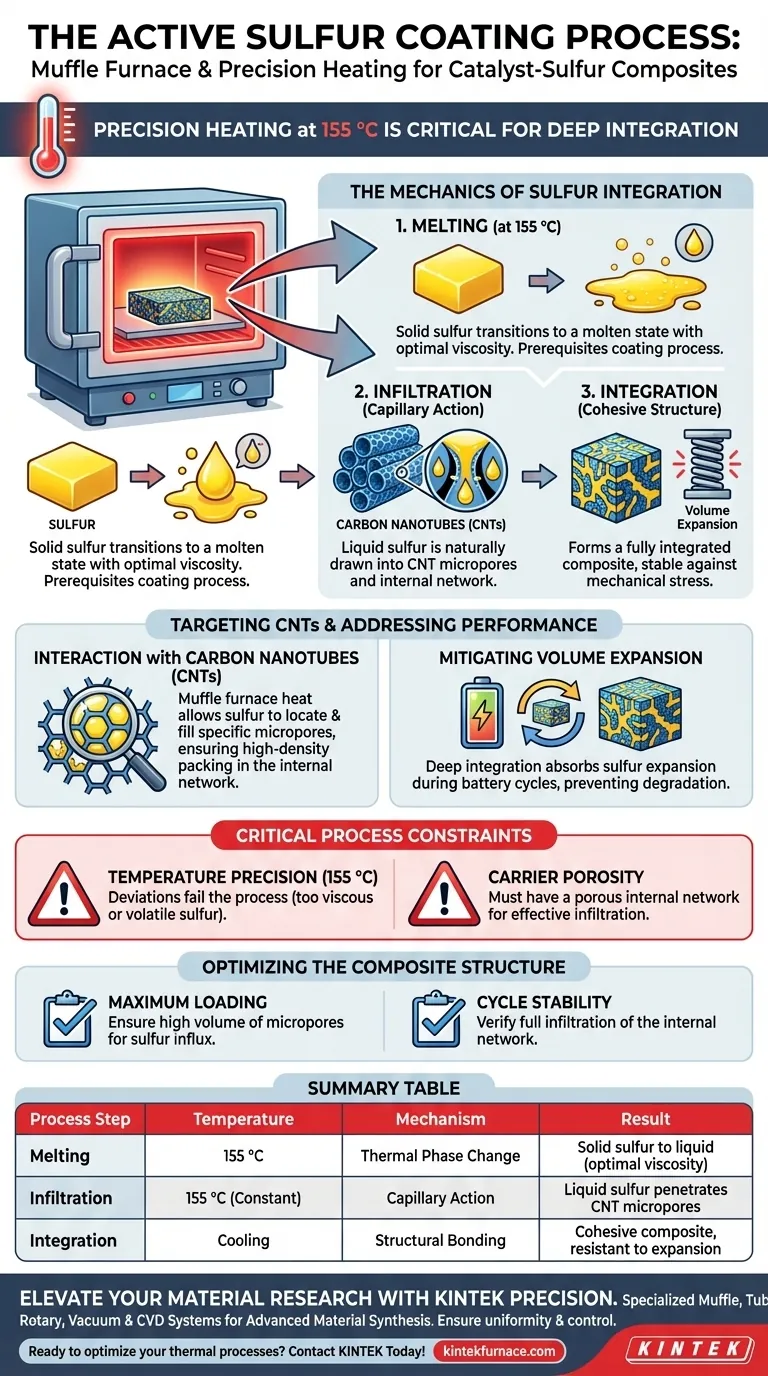

The Mechanics of Sulfur Integration

Reaching the Critical Melt Point

The primary function of the muffle furnace is to heat the composite mixture to 155 °C.

At this specific temperature, solid sulfur melts into a liquid phase with optimal viscosity. This phase change is the prerequisite for the coating process to begin.

Utilizing Capillary Action

Once the sulfur is molten, the process relies on capillary action.

The liquid sulfur is drawn naturally into the microscopic voids of the carrier material. This ensures the sulfur does not just coat the exterior but penetrates the internal architecture of the composite.

Interaction with Carbon Nanotubes (CNTs)

Targeting the Micropores

The reference specifically highlights the interaction between sulfur and Carbon Nanotubes (CNTs).

The muffle furnace's heat allows the sulfur to locate and fill the specific micropores found within the CNT structure. This results in a high-density packing of the active material.

Saturating the Internal Network

Beyond surface pores, the process targets the internal network of the CNTs.

Deep infiltration ensures that the sulfur and the carrier form a cohesive, integrated unit. This structural unity is superior to a superficial surface coating.

Addressing Battery Performance

Mitigating Volume Expansion

The ultimate goal of this thermal process is to solve a specific mechanical problem: volume expansion.

During battery charge and discharge cycles, sulfur naturally expands and contracts.

By integrating the sulfur deep within the CNT network via the muffle furnace process, the composite can better absorb these physical changes without degrading, leading to better stability.

Critical Process Constraints

Dependence on Temperature Precision

The success of this method hinges entirely on maintaining the temperature at 155 °C.

Deviations from this temperature could result in sulfur that is too viscous to infiltrate pores or too volatile to remain stable.

Reliance on Carrier Porosity

This application is only effective if the carrier material possesses a porous internal network.

The muffle furnace facilitates infiltration, but it cannot force integration if the Carbon Nanotubes do not have sufficient micropores to accept the liquid sulfur.

Optimizing the Composite Structure

To ensure the highest quality catalyst-sulfur composite, consider the following based on your specific objectives:

- If your primary focus is Maximum Loading: Ensure the carrier material has a high volume of micropores to accommodate the sulfur influx at 155 °C.

- If your primary focus is Cycle Stability: Verify that the sulfur has fully infiltrated the internal network to prevent mechanical stress during volume expansion.

Precision heating is the key to transforming raw sulfur and CNTs into a unified, high-performance battery material.

Summary Table:

| Process Step | Temperature | Mechanism | Result |

|---|---|---|---|

| Melting | 155 °C | Thermal Phase Change | Solid sulfur transitions to optimal viscosity liquid |

| Infiltration | 155 °C (Constant) | Capillary Action | Liquid sulfur penetrates CNT micropores and internal networks |

| Integration | Cooling | Structural Bonding | Forms a cohesive composite resistant to volume expansion |

Elevate Your Material Research with KINTEK Precision

High-performance battery materials like catalyst-sulfur composites require absolute thermal accuracy to ensure successful capillary infiltration and structural stability. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for advanced material synthesis. Whether you need to maintain a precise 155 °C for sulfur coating or require a fully customizable high-temperature furnace for unique lab requirements, our solutions deliver the uniformity and control you need.

Ready to optimize your lab's thermal processes? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Yulin Luo, Qi-Hui Wu. Carbon Nanotubes-Doped Metal Oxides and Metal Sulfides Heterostructure Achieves 3D Morphology Deposition of Li2S and Stable Long-Cycle Lithium–Sulfur Batteries. DOI: 10.3390/inorganics13060181

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace differ from a conventional oven? Key Differences for High-Temperature Precision

- What substances should never be introduced into a muffle furnace? Protect Your Equipment from Damage

- What are the different types of muffle furnaces and their features? Choose the Right One for Your Lab

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- Why is a box muffle furnace required for In2O3 nanofibers? Expert Synthesis & Pre-Oxidation Guide

- What are the thermal insulation materials used in muffle furnaces? Choose the Right Insulation for Efficiency and Durability

- What role does a muffle furnace play during the isothermal spheroidizing annealing of high-carbon bearing steel?

- What are some key features of premium muffle furnaces? Unlock Superior Performance and Safety