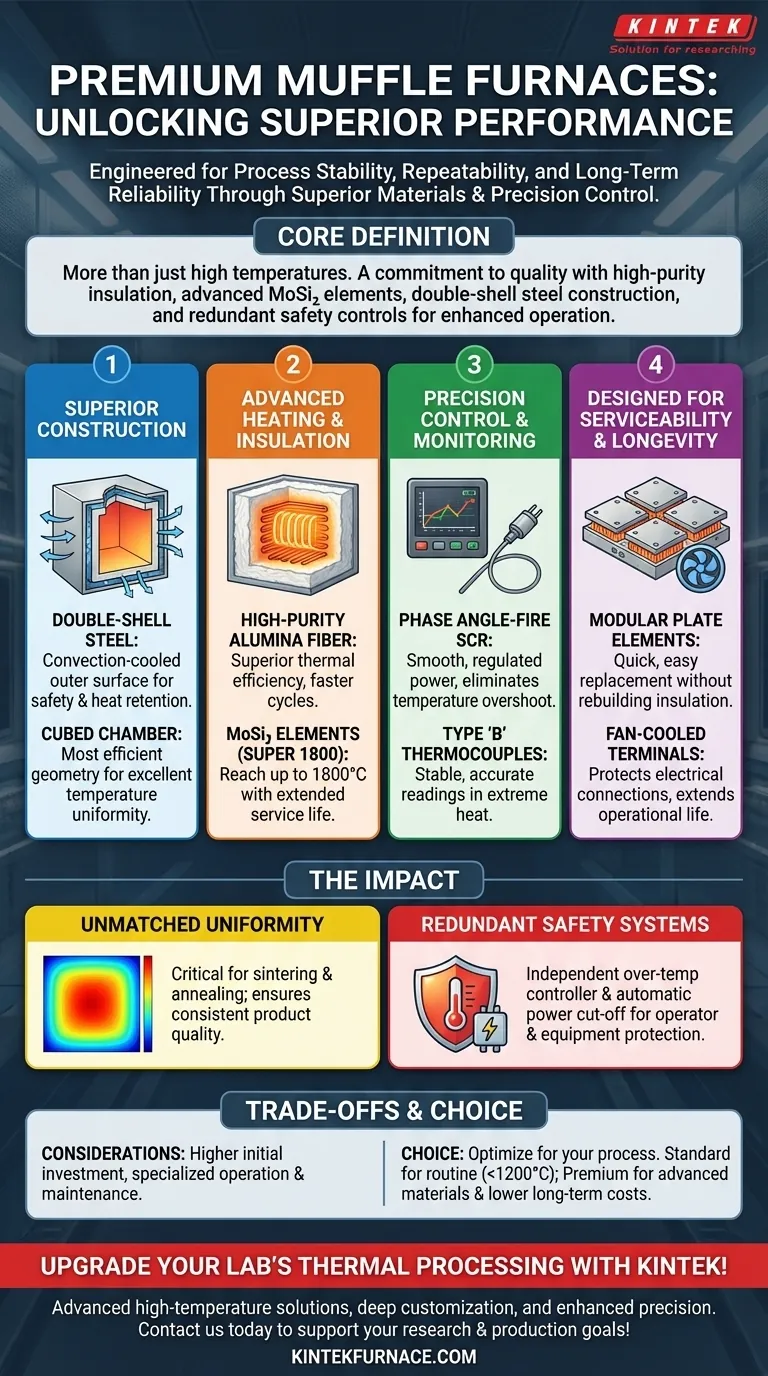

At their core, premium muffle furnaces are defined by superior materials, precision control systems, and designs engineered for reliability and serviceability. Key features include high-purity insulation, advanced molybdenum disilicide heating elements, double-shell steel construction, and redundant safety controls. These components work together to deliver higher temperatures, better uniformity, and greater operational safety than standard models.

The distinction of a "premium" muffle furnace is not just its ability to reach higher temperatures. It represents a fundamental commitment to process stability, repeatability, and long-term reliability, which is achieved through superior engineering and higher-grade components.

What Defines a Premium Muffle Furnace?

A premium furnace is an integrated system where each component is chosen to enhance performance, safety, and longevity. These features go far beyond what is found in a basic laboratory unit.

Superior Construction for Durability and Uniformity

A furnace's physical build is the foundation of its performance. Double-shell steel construction creates a convection-cooled outer surface, keeping the exterior safe to touch while improving heat retention.

This is often paired with a cubed chamber design. A cube offers the most efficient geometry for achieving excellent temperature uniformity, ensuring that all parts of a sample are exposed to the same thermal conditions.

Advanced Heating and Insulation

Premium models use materials designed for extreme environments. High-purity alumina fiber insulation provides excellent thermal efficiency, reducing heat loss and allowing for faster heat-up and cool-down cycles.

Heating is typically provided by Super 1800 Molybdenum Disilicide (MoSi₂) elements. These are capable of reaching temperatures up to 1800°C and offer long service life, far exceeding the capabilities of elements in standard furnaces.

Precision Control and Monitoring

Achieving and holding a precise temperature is critical. Premium furnaces utilize phase angle-fire SCR power controllers to deliver smooth, highly regulated power to the heating elements, eliminating the temperature "overshoot" common in simpler on/off controllers.

Temperature is measured with high-accuracy sensors like Type 'B' thermocouples, which are specifically designed for stable and accurate readings in high-temperature environments.

Designed for Serviceability and Longevity

Downtime is a critical concern in production and research. Modular plate heating elements are a key feature, allowing for quick and easy replacement without needing to rebuild the entire insulation chamber.

To protect critical components, these furnaces also incorporate fan cooling of element terminals, preventing the high heat from the chamber from damaging the electrical connections and extending the furnace's operational life.

The Impact on Performance and Safety

These individual features combine to create tangible benefits that justify the investment in a premium unit. The primary advantages are seen in process results, operational cost, and user safety.

Unmatched Temperature Uniformity

The combination of a cubed chamber, advanced insulation, and precision power control results in exceptionally uniform heat distribution. This is non-negotiable for processes like sintering or annealing, where even minor temperature variations can compromise the final product.

Redundant Safety Systems

Safety is paramount when working with extreme heat. A key feature of a premium furnace is an independent over-temperature controller. This separate system monitors the furnace temperature and will shut down power if it exceeds a set safety limit, providing a crucial failsafe if the primary controller malfunctions.

This is backed by circuit breakers that automatically cut all power in the event of an electrical fault, protecting both the operator and the equipment.

Understanding the Trade-offs

While the advantages are significant, it's important to understand the associated considerations.

Initial Investment

Premium muffle furnaces represent a significantly higher upfront capital investment compared to standard models. This cost is a direct reflection of the higher-grade materials, advanced controllers, and more robust engineering.

Specialized Operation and Maintenance

The precision of these instruments requires trained personnel. Proper operation, programming of heating profiles, and routine maintenance—such as verifying calibration and inspecting elements—are necessary to ensure the furnace performs to its specifications over its lifespan.

Making the Right Choice for Your Application

Selecting the correct furnace requires aligning its capabilities with your specific process goals.

- If your primary focus is routine processes below 1200°C (like ashing): A standard furnace may be sufficient, but a premium model will offer superior reliability and process consistency.

- If your primary focus is advanced materials research (like sintering ceramics): The temperature capability, uniformity, and precision control of a premium high-temperature furnace are essential for achieving valid, repeatable results.

- If your primary focus is optimizing long-term operational costs: The energy efficiency and serviceability of a premium furnace can lead to a lower total cost of ownership, offsetting the higher initial investment.

Ultimately, choosing a premium furnace is an investment in the precision, repeatability, and safety of your thermal processing operations.

Summary Table:

| Feature | Description |

|---|---|

| Superior Construction | Double-shell steel and cubed chamber for durability and uniformity |

| Advanced Heating | Molybdenum disilicide elements up to 1800°C with long service life |

| Precision Control | Phase angle-fire SCR controllers and Type 'B' thermocouples for accuracy |

| Safety Systems | Independent over-temperature controllers and circuit breakers for protection |

| Serviceability | Modular elements and fan cooling for easy maintenance and longevity |

Upgrade your lab's thermal processing with KINTEK's premium muffle furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, delivering enhanced precision, safety, and efficiency. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production