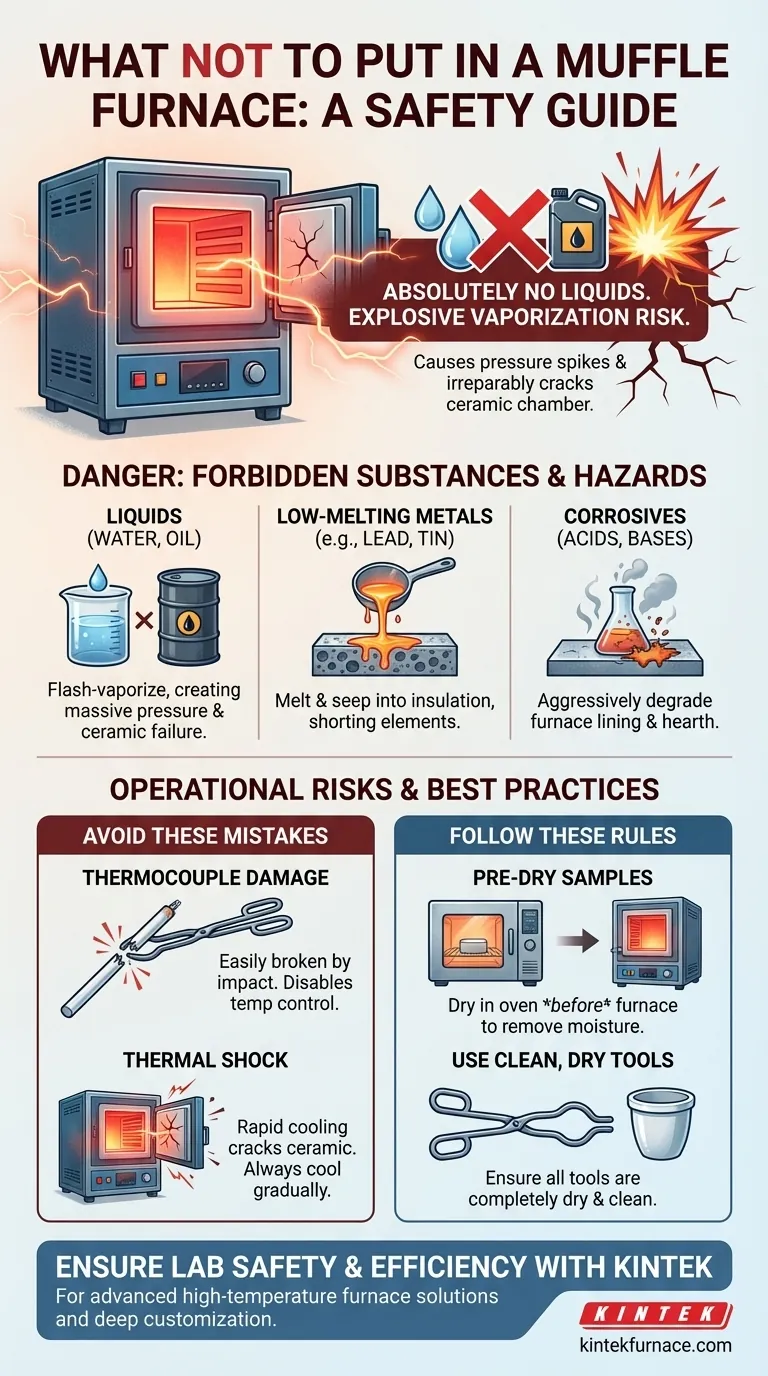

Above all, you must never introduce any liquids into a muffle furnace. This includes samples containing water or oil, as well as tools like tongs or clips that are wet or oily. Additionally, low-melting-point metals and highly corrosive substances should be kept out of the furnace chamber to prevent irreversible damage.

The core principle is to protect the furnace’s ceramic interior. Liquids vaporize with explosive force at high temperatures, causing pressure spikes that crack the chamber, while molten metals and corrosive materials can chemically degrade the heating elements and refractory lining.

The Primary Dangers: Volatiles and Corrosives

A muffle furnace operates at extreme temperatures, typically from 300°C to over 1200°C. At these temperatures, materials behave in ways that can be destructive to the equipment if not properly managed.

The Hazard of Water and Oil

Any liquid introduced into the hot zone of a muffle furnace will flash-vaporize almost instantly. This rapid phase change from liquid to gas creates a massive and sudden increase in volume and pressure.

This pressure spike can easily crack or shatter the brittle ceramic muffle (the furnace's inner chamber). Even a small amount of water or oil on a sample or the tongs used to handle it is enough to cause significant damage.

The Problem with Low-Melting-Point Metals

The term "soluble metals" from operational manuals generally refers to metals with a low melting point relative to the furnace's operating temperature.

When these metals melt, they can seep into the porous surface of the ceramic muffle and insulation. This can short-circuit the internal heating elements or react chemically with the refractory materials, leading to corrosion and catastrophic equipment failure.

The Threat from Corrosive Substances

Strong alkaline substances (bases) or acids should not be placed directly onto the furnace floor. At high temperatures, these materials become highly reactive and can aggressively corrode the furnace's hearth plate and internal lining.

If you must heat such materials, they should be contained within a suitable crucible, which may itself be placed on a protective refractory plate as an additional barrier.

Protecting Furnace Integrity and Sample Accuracy

Beyond forbidden substances, proper operational procedure is critical for ensuring the longevity of the furnace and the quality of your results.

The Thermocouple is Fragile

The thermocouple is the furnace's temperature sensor, often extending into the chamber as a thin ceramic rod. It is extremely brittle, especially when hot.

Accidentally bumping the thermocouple with a crucible or tongs can easily break it. This will disable the furnace's temperature control, rendering it unusable until a costly repair is made.

The Risk of Thermal Shock

The ceramic components of a muffle furnace cannot withstand rapid temperature changes. Opening the door fully while the furnace is at a high temperature will cause a sudden rush of cool air, creating thermal shock.

This will crack the furnace chamber or door insulation. The correct procedure is to shut off the power, then crack the door open just a small amount to allow for a more gradual, controlled cooling before removing your items.

Preventing Sample Contamination

Careful handling also prevents contamination. For sensitive analyses, you can wrap samples or the open ends of glass vessels in aluminum foil.

This protects your sample from any potential particles within the furnace and, conversely, protects the furnace from any materials that might outgas from your sample.

Common Pitfalls to Avoid

Understanding the principles allows you to avoid common but costly mistakes that often happen in a lab setting.

Forgetting to Pre-Dry Samples

While "wet" samples are forbidden, the entire purpose of ashing is often to burn off residual moisture and organics. The critical mistake is not pre-drying.

Samples with significant moisture content must be thoroughly dried in a standard laboratory oven (e.g., at 105°C) before being placed into the muffle furnace. The furnace is for high-temperature treatment, not bulk water removal.

Using Contaminated or Improper Tools

The prohibition on wet or oily materials extends to every item that enters the furnace. Using tongs that were just rinsed with water or a crucible that wasn't fully dried is a common cause of damage.

Ensure all tools and containers are completely dry and clean. Always use crucible tongs specifically designed for high-temperature work to handle items.

Making the Right Choice for Safe Operation

Following a strict protocol is not about arbitrary rules; it is about managing the extreme energy of a high-temperature environment to ensure safety and equipment longevity.

- If your primary focus is equipment longevity: Always pre-dry samples and tools, and cool the furnace gradually after use to prevent thermal shock to the ceramic chamber.

- If your primary focus is analytical accuracy: Use clean, dedicated crucibles and consider protective wraps to prevent cross-contamination between your sample and the furnace environment.

- If your primary focus is operator safety: Never introduce liquids or volatile materials that can cause explosive vaporization and catastrophic failure of the furnace chamber.

Ultimately, treating a muffle furnace with a deep understanding of its thermal and chemical vulnerabilities is the key to safe and effective operation.

Summary Table:

| Substance Type | Examples | Potential Damage |

|---|---|---|

| Liquids | Water, oil | Explosive vaporization, cracks ceramic chamber |

| Low-melting-point metals | Lead, tin | Melts, seeps into insulation, shorts heating elements |

| Corrosive substances | Acids, bases | Corrodes furnace lining and hearth plate |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can support your operations and prevent costly equipment failures!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control