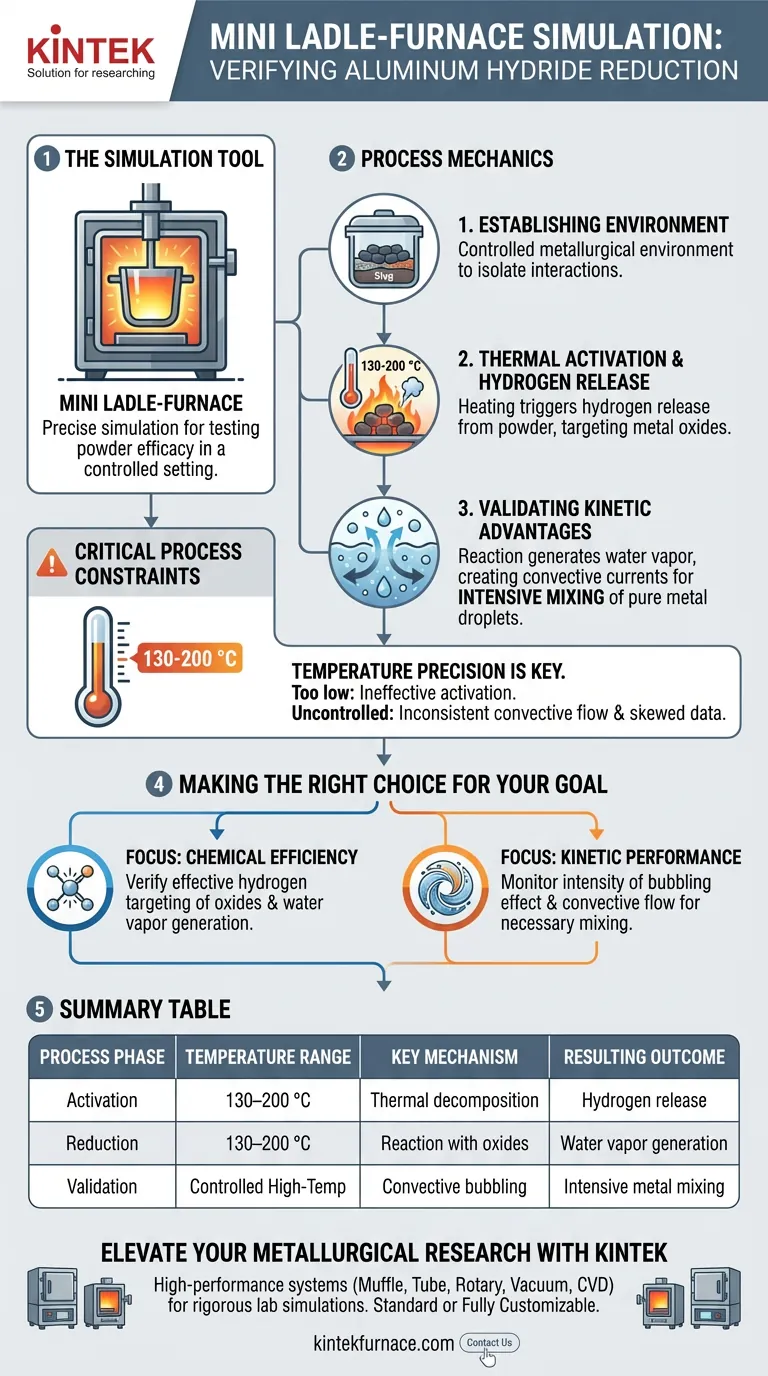

A mini ladle-furnace serves as a precise simulation tool for testing the efficacy of aluminum hydride powder in a controlled setting. It functions by heating briquettes containing the powder within a slag layer to a specific temperature range, triggering a chemical reaction that reduces metal oxides and validates the kinetic behavior of the materials.

The simulation validates the effectiveness of alumino-hydrogen reduction by inducing a dynamic interaction between released hydrogen and the molten environment. This process generates water vapor and convective currents, which are essential for the intensive mixing and separation of pure metal droplets.

The Mechanics of the Simulation

Establishing the Environment

The mini ladle-furnace is designed to create a controlled metallurgical environment. This isolation allows researchers to observe specific chemical interactions without the variables present in full-scale industrial operations.

Thermal Activation

The process begins when briquettes containing aluminum hydride powder are introduced to the slag layer. The system is heated to a critical range of 130 to 200 °C.

Hydrogen Release

Upon reaching this temperature window, the powder creates a reaction where hydrogen is released. This hydrogen targets and reduces the metal oxides present in the mixture.

Validating Kinetic Advantages

The Role of Water Vapor

The reduction reaction produces water vapor as a byproduct. In this simulation, the vapor acts as a loosening agent within the slag layer.

Creating Fluid Dynamics

The release of vapor creates a distinct bubbling effect. This bubbling drives convective fluid flow throughout the molten mixture.

Intensive Mixing

The convective flow promotes the intensive mixing of pure metal droplets within the molten steel. This physical agitation is the key indicator that validates the kinetic advantages of the alumino-hydrogen reduction process.

Critical Process Constraints

Temperature Precision

The success of this verification relies entirely on maintaining the specific 130-200 °C temperature window.

If the temperature is too low, the hydrogen release mechanism may not activate sufficiently to reduce the oxides. If the heating is uncontrolled, the rate of water vapor generation may differ, altering the convective flow and skewing the data regarding kinetic effectiveness.

Making the Right Choice for Your Goal

When analyzing results from a mini ladle-furnace simulation, focus on the specific physical indicators that align with your objectives.

- If your primary focus is Chemical Efficiency: Verify that the hydrogen release effectively targets metal oxides, resulting in the generation of water vapor.

- If your primary focus is Kinetic Performance: Monitor the intensity of the bubbling effect and convective flow to ensure it creates the necessary mixing of metal droplets.

This simulation method provides the definitive proof required to validate the alumino-hydrogen process before moving to larger applications.

Summary Table:

| Process Phase | Temperature Range | Key Mechanism | Resulting Outcome |

|---|---|---|---|

| Activation | 130–200 °C | Thermal decomposition of briquettes | Hydrogen release |

| Reduction | 130–200 °C | Reaction with metal oxides | Water vapor generation |

| Validation | Controlled High-Temp | Convective bubbling & fluid flow | Intensive metal mixing |

Elevate Your Metallurgical Research with KINTEK

Ready to validate your reduction processes with precision? Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed for rigorous laboratory simulations. Whether you need a standard setup or a fully customizable furnace tailored to your unique kinetic studies, our equipment ensures the temperature stability and control essential for your success.

Contact us today to find the perfect high-temp solution for your lab!

Visual Guide

References

- Gigo Jandieri, Giorgi Sakhvadze. Hydrated aluminum powder for direct alloying of steel and alloys - challenges of the future. DOI: 10.51582/interconf.19-20.03.2024.044

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of vacuum induction furnace melting for superalloys? Achieve Purity and Performance

- How do MgO crucibles affect melt purity? Strategies for High-Purity Vacuum Induction Remelting

- What are the environmental benefits of using an IGBT induction melting furnace? Boost Efficiency & Cut Emissions

- What is an induction gold melting furnace and how does it work? Achieve Purity, Speed, and Efficiency

- How does precise temperature control in induction furnaces benefit gold melting? Maximize Purity & Minimize Loss

- Can a Vacuum Induction Melting Furnace be used to melt stainless steel? Achieve High-Purity Alloys for Critical Applications

- What technological advancements are shaping the IGBT induction melting furnace market? Unlock Intelligent, Efficient Melting

- What is the function of the melting furnace and stirring device in AFS precursor preparation? Optimize Melt Stability