Yes, absolutely. A Vacuum Induction Melting (VIM) furnace is not only capable of melting stainless steel, but it is often the preferred method for producing high-purity and high-performance grades. The furnace can easily reach the required melting temperatures, while its core feature—the vacuum—provides significant advantages for controlling the final quality of the alloy.

The question is not whether a VIM furnace can melt stainless steel, but why you would choose it. The defining feature of a VIM is its vacuum environment, which prevents oxidation and removes impurities, making it ideal for creating exceptionally clean stainless steel for demanding applications.

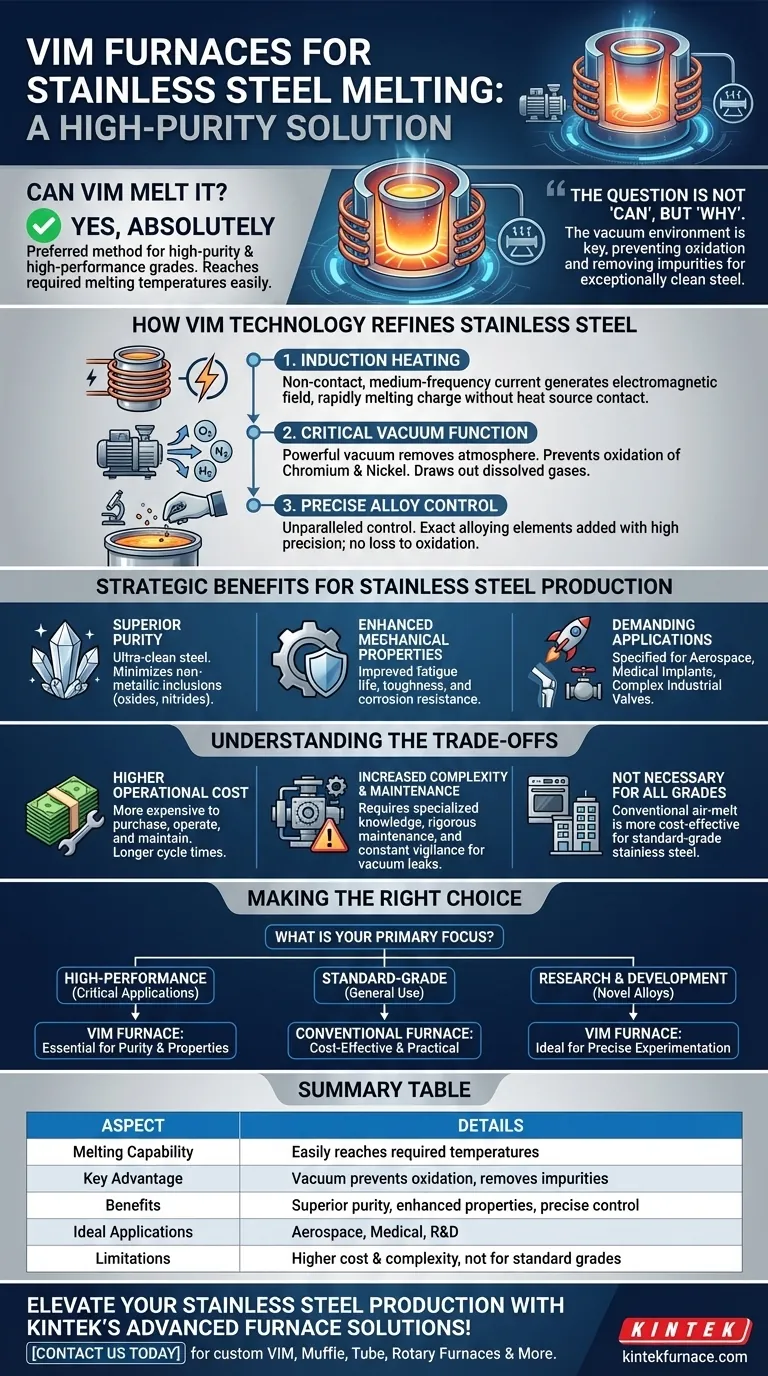

How VIM Technology Refines Stainless Steel

To understand the value of a VIM furnace, you must look beyond simple melting and focus on the metallurgical refinement that occurs during the process.

The Role of Induction Heating

A powerful copper coil, called an inductor, surrounds the crucible containing the raw stainless steel material. A medium-frequency electrical current is passed through this coil.

This generates a strong electromagnetic field that induces eddy currents within the steel charge, heating and melting it efficiently and rapidly without any direct contact from a heat source.

The Critical Function of the Vacuum

This is the key differentiator. Before and during melting, a powerful vacuum system removes the atmosphere from the furnace chamber.

This near-vacuum environment prevents oxygen, nitrogen, and other atmospheric gases from reacting with the molten metal. For stainless steel, this is crucial for preventing the oxidation of essential and expensive alloying elements like chromium and nickel.

It also helps draw out dissolved gases like hydrogen from the molten bath, which can otherwise lead to porosity and embrittlement in the final cast product.

Precise Control Over Alloy Chemistry

With atmospheric interference eliminated, metallurgists have unparalleled control over the final composition. Alloying elements can be added with high precision, knowing they won't be lost to oxidation. This ensures the final product meets exact chemical specifications every time.

The Strategic Benefits for Stainless Steel Production

Using a VIM furnace is a deliberate choice to achieve a higher standard of material quality. The benefits directly address common challenges in alloy manufacturing.

Superior Purity and Cleanliness

The primary benefit is the production of ultra-clean steel. The vacuum environment minimizes the formation of non-metallic inclusions (like oxides and nitrides), which are microscopic impurities that can compromise the metal's integrity.

Enhanced Mechanical Properties

Cleaner steel translates directly to better performance. Stainless steel produced in a VIM furnace exhibits improved fatigue life, toughness, and corrosion resistance because the common points of failure (inclusions) have been drastically reduced.

Suitability for Demanding Applications

This high level of quality is why VIM-produced stainless steel is specified for critical components in industries like aerospace, medical implants, and complex industrial valves. In these fields, material failure is not an option.

Understanding the Trade-offs

While powerful, a VIM furnace is not the universal solution for all stainless steel melting. Objectivity requires acknowledging its specific role and limitations.

Higher Operational Cost

VIM furnaces are more expensive to purchase, operate, and maintain than standard atmospheric induction or electric arc furnaces. The vacuum pumps, seals, and longer cycle times contribute to a higher cost per ton of metal produced.

Increased Complexity and Maintenance

Operating a high-vacuum system requires specialized knowledge and rigorous maintenance schedules. Leaks in the vacuum seals can compromise an entire batch, demanding constant vigilance from the operating team.

Not Necessary for All Grades

For general-purpose stainless steel used in applications like kitchen appliances, architectural elements, or standard fasteners, the high purity of VIM is often unnecessary. A conventional air-melt furnace provides a far more cost-effective solution for these common grades.

Making the Right Choice for Your Application

Your decision to use a VIM furnace should be guided entirely by the end-use requirements of the stainless steel alloy.

- If your primary focus is high-performance stainless steel for critical applications: The purity, chemical precision, and enhanced mechanical properties offered by a VIM furnace are essential.

- If your primary focus is producing standard-grade stainless steel for general use: A conventional air-melt induction or electric arc furnace is the more cost-effective and practical solution.

- If your primary focus is research and development of novel alloys: The highly controlled environment of a VIM furnace provides the ideal platform for precise experimentation.

Ultimately, choosing a VIM furnace is a strategic decision to prioritize final material quality and performance over initial production cost.

Summary Table:

| Aspect | Details |

|---|---|

| Melting Capability | Easily reaches required temperatures for stainless steel melting. |

| Key Advantage | Vacuum environment prevents oxidation and removes impurities. |

| Benefits | Superior purity, enhanced mechanical properties, precise alloy control. |

| Ideal Applications | Aerospace, medical implants, industrial valves, and R&D. |

| Limitations | Higher cost and complexity; not needed for standard grades. |

Elevate your stainless steel production with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom VIM furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for high-purity alloys. Contact us today to discuss how our solutions can optimize your processes and deliver superior results for critical applications!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why are graphite crucibles and induction furnaces equipped with protective gas systems used for Zn-SiC composites?

- What is the induction coil and how is it constructed? Master High-Efficiency Heating with Expert Designs

- Why Use an Argon Arc Melting Furnace for MnCoNiCuGe5 Alloys? Ensuring Purity in High-Entropy Brazing

- What makes graphite crucible furnaces suitable for high-temperature applications? Unlock Precision and Purity

- What solutions are implemented for vacuum induction melting (VIM)? Achieve Superior Alloy Purity and Performance

- What role does a vacuum induction furnace play in melting Fe-C-Mn-Si alloy steels? Ensure Purity & Precision

- Why use vacuum arc furnaces and copper mold suction casting for Ti-xNb alloys? Key to Biomedical Material Excellence

- What role does a high-vacuum melting furnace play in the modification of Ni 620 brazing filler metal with tungsten?