The primary environmental benefits of an IGBT induction melting furnace stem from its significant gains in energy efficiency and its minimal electrical pollution. Unlike older technologies, these furnaces use modern power electronics to reduce energy waste during the melting process and to avoid contaminating the electrical grid with harmful interference.

The shift to IGBT induction furnaces is less about a single "green" feature and more about a fundamental upgrade in power electronics. By replacing older, less efficient Silicon Controlled Rectifier (SCR) technology, IGBTs provide superior electrical control, which directly translates into reduced energy waste, lower operational costs, and a cleaner power grid.

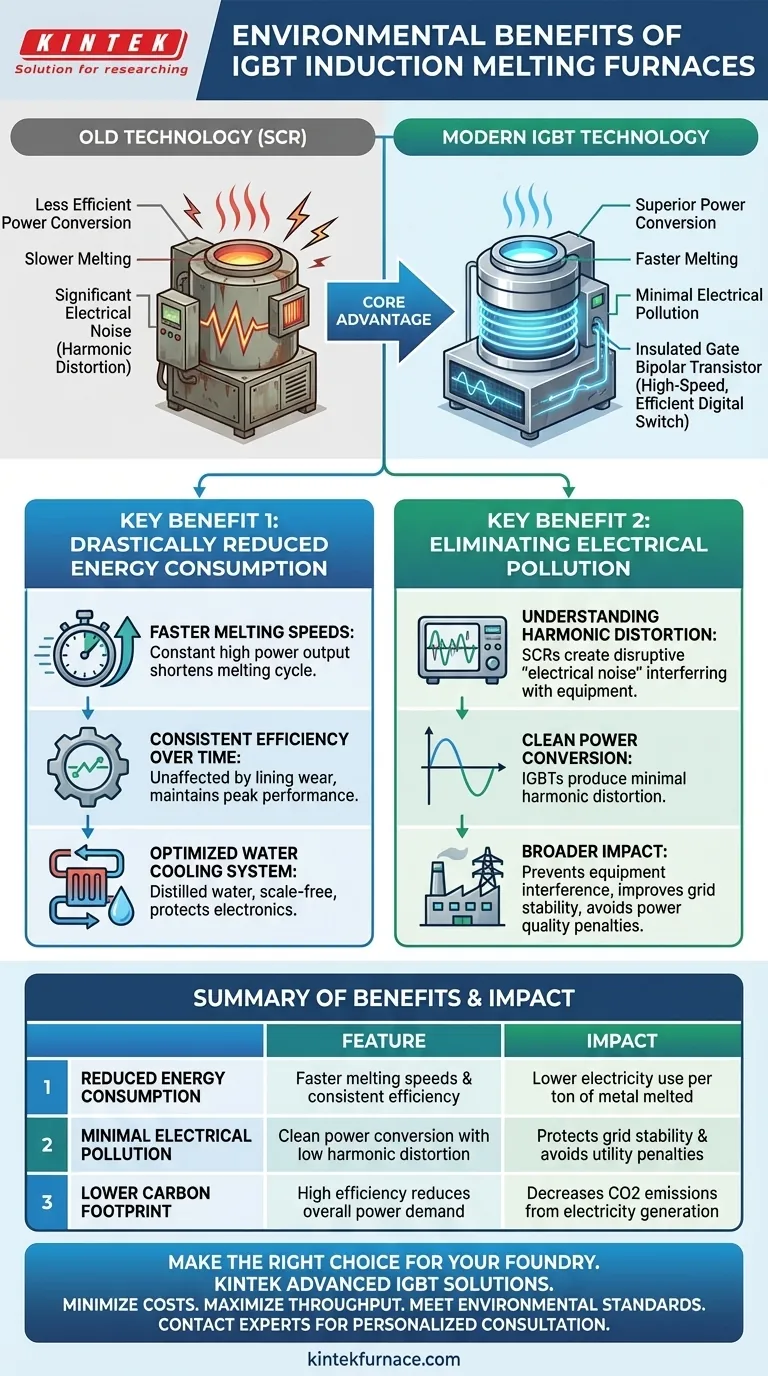

The Core Advantage: Superior Power Conversion

At the heart of an IGBT furnace's environmental performance is the technology itself. The benefits are a direct result of a more advanced way of managing high-power electricity.

What is IGBT Technology?

An IGBT, or Insulated Gate Bipolar Transistor, is a modern, high-speed semiconductor. Think of it as a highly efficient digital switch that can turn power on and off thousands of times per second with minimal energy loss.

This rapid, clean switching is the key to the furnace's efficiency and control.

Replacing Outdated SCR Technology

Older induction furnaces typically rely on Silicon Controlled Rectifiers (SCRs). SCRs are a dated technology that is less efficient at converting power. They are slower and less precise, creating significant energy loss and electrical "noise" as a byproduct of their operation.

The Impact on Energy Consumption

Because IGBTs are far more efficient switches, they minimize energy wastage during the AC-to-DC-to-AC power conversion required for induction heating. This fundamental efficiency improvement is the source of the furnace's most significant environmental benefit: using less power to melt the same amount of metal.

Key Benefit 1: Drastically Reduced Energy Consumption

Lower energy consumption is the most direct environmental and economic advantage. This is achieved through several synergistic features.

Faster Melting Speeds

IGBT furnaces are designed to deliver constant, high power output throughout the entire melting cycle. This melts the metal faster, reducing the total time the furnace must draw electricity and thereby lowering the kilowatt-hours consumed per ton of metal.

Consistent Efficiency Over Time

The furnace’s power output is unaffected by the thickness of the refractory lining or the electrical characteristics of the metal load. Older systems often lose efficiency as the lining wears, but IGBT systems maintain their peak performance consistently, ensuring long-term energy savings.

Optimized Water Cooling System

These furnaces use a closed-loop system with distilled water and a heat exchanger. This prevents the buildup of mineral scale in the cooling passages, which is a common problem in systems using raw water. A scale-free system ensures electronics are cooled effectively, preventing component failure and maintaining peak operational efficiency.

Key Benefit 2: Eliminating Electrical Pollution

Beyond consuming less energy, IGBT furnaces are better "citizens" on the electrical grid. They avoid a problem known as harmonic distortion, which can have facility-wide consequences.

Understanding Harmonic Distortion

SCR-based furnaces generate significant "electrical noise," or harmonic distortion, which pollutes the factory's power grid. This is like static on a radio line—it can interfere with the operation of other sensitive electronic equipment, from computers to CNC machines.

How IGBTs Create a Cleaner Grid

The clean, precise, and high-frequency switching of IGBTs produces minimal harmonic distortion. The furnace draws power from the grid smoothly, without creating the disruptive electrical interference characteristic of older SCR systems.

The Broader Impact

Operating with low harmonics prevents interference with other factory equipment, improves the overall stability of the electrical network, and helps the facility avoid potential power quality penalties from the utility provider.

Understanding the Trade-offs

While highly beneficial, adopting IGBT technology requires a clear understanding of the associated considerations.

Higher Initial Investment

Modern IGBT systems typically have a higher upfront capital cost compared to traditional SCR-based units. This cost, however, is often quickly offset by significant operational savings in energy, maintenance, and productivity.

Complexity of Electronics

The advanced digital controls, often using DSP or ARM processors, are extremely powerful and reliable. However, troubleshooting and deep maintenance may require more specialized technical expertise compared to simpler, older analog systems.

Sensitivity to Incoming Power

While IGBT systems produce very clean power, their sophisticated electronics can be sensitive to poor power quality coming from the grid. They perform best when connected to a stable and reliable power source, which is a key consideration in some industrial areas.

Making the Right Choice for Your Foundry

The decision to invest in an IGBT furnace should be aligned with your specific operational priorities.

- If your primary focus is minimizing operational costs: The long-term energy savings and reduced maintenance needs of IGBT technology will almost certainly provide a lower total cost of ownership.

- If your primary focus is maximizing production throughput: The faster melting speeds and constant power output of an IGBT furnace directly increase the tons of metal you can process per shift.

- If your primary focus is meeting environmental standards or grid compliance: The low harmonic distortion of an IGBT furnace is a non-negotiable advantage, protecting your equipment and satisfying utility requirements.

Ultimately, adopting an IGBT induction furnace is a strategic decision that aligns environmental responsibility with significant gains in operational performance and efficiency.

Summary Table:

| Environmental Benefit | Key Feature | Impact |

|---|---|---|

| Reduced Energy Consumption | Faster melting speeds & consistent efficiency | Lower electricity use per ton of metal melted |

| Minimal Electrical Pollution | Clean power conversion with low harmonic distortion | Protects grid stability & avoids utility penalties |

| Lower Carbon Footprint | High efficiency reduces overall power demand | Decreases CO2 emissions from electricity generation |

Ready to make your foundry operations greener and more profitable? KINTEK's advanced IGBT induction melting furnaces are engineered to deliver maximum energy efficiency and minimal environmental impact. Leveraging our exceptional R&D and in-house manufacturing, we provide robust solutions like our Muffle, Tube, and Vacuum Furnaces, with deep customization capabilities to precisely meet your unique production needs. Lower your operational costs and boost your sustainability credentials – contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How is operator safety ensured during the vacuum induction melting process? Discover Multi-Layered Protection for Your Lab