At its core, a laboratory tube furnace is used in electronic and semiconductor research to perform precise thermal processing on materials like silicon wafers. Key applications include diffusion and doping to alter electrical conductivity, oxidation to grow insulating layers, and annealing to repair crystal structures and activate dopants.

The true value of a tube furnace isn't just its ability to get hot; it's the power to create an extremely uniform and controlled environment. This precision is what allows researchers to manipulate material properties at the atomic level, which is the fundamental basis for creating functional semiconductor devices.

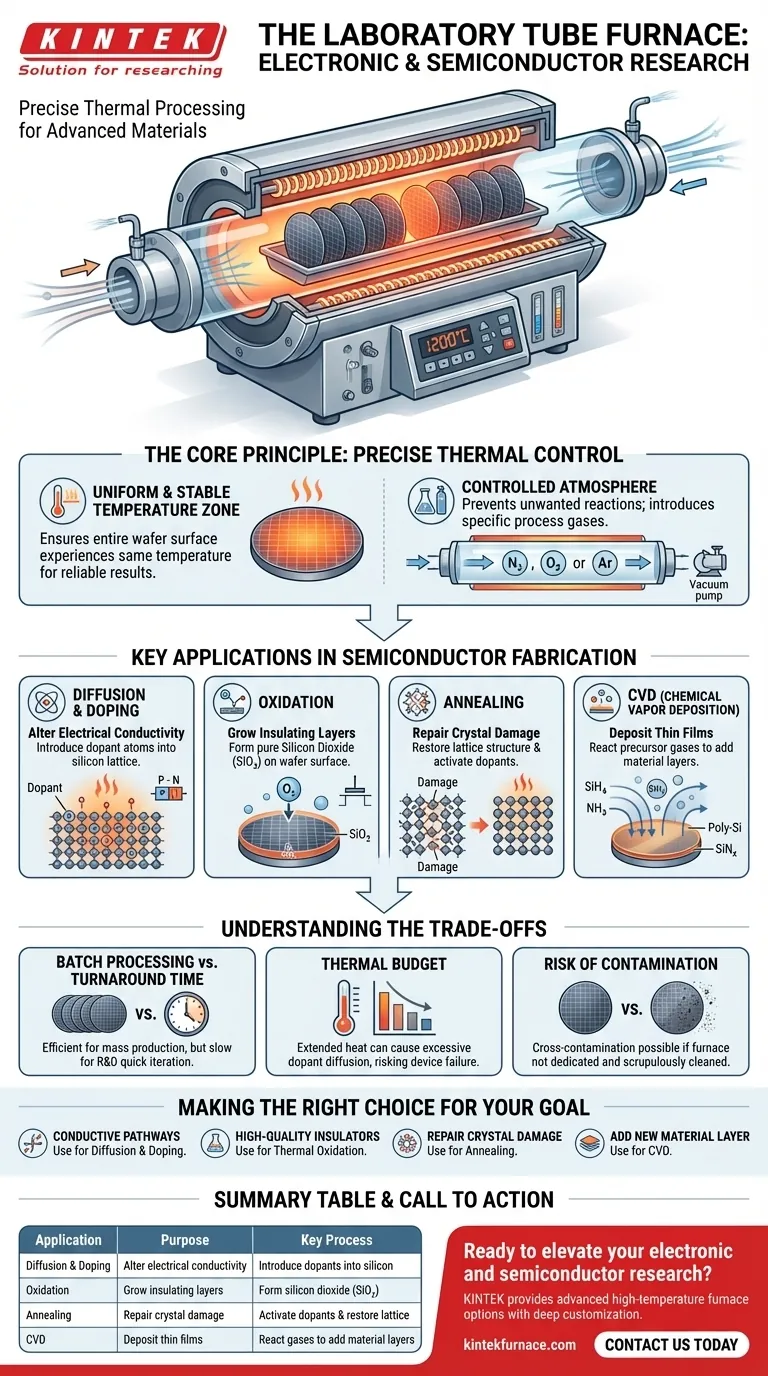

The Core Principle: Precise Thermal Control

The function of every modern electronic device relies on the specific properties of the semiconductor materials inside it. A tube furnace provides the two critical conditions needed to modify these properties with high precision.

Uniform and Stable Temperature Zone

A tube furnace is designed to create a long, consistent heating zone. When a silicon wafer or other substrate is placed inside the tube, its entire surface experiences the same temperature, ensuring uniform processing results across the device.

This uniformity is non-negotiable for creating reliable transistors and integrated circuits, where even minor variations can lead to device failure.

Controlled Atmosphere

The tube can be sealed and either evacuated to a vacuum or filled with a specific process gas. This controlled atmosphere prevents unwanted reactions (like oxidation from air) and introduces the exact chemical reactants needed for a given process.

Key Applications in Semiconductor Fabrication

The controlled environment of a tube furnace enables several foundational steps in turning a pure silicon wafer into a complex integrated circuit.

Diffusion and Doping

Doping is the process of intentionally introducing impurity atoms (dopants) into the semiconductor crystal to change its electrical properties, creating P-type or N-type regions.

A tube furnace facilitates diffusion, where high heat gives the dopant atoms enough energy to move, or diffuse, into the silicon lattice. The temperature and time precisely control how deep and concentrated the dopant profile is.

Oxidation

Semiconductor devices require high-quality insulating layers. A tube furnace is used for thermal oxidation, where silicon wafers are heated in an atmosphere containing oxygen or water vapor.

This process grows an exceptionally pure and uniform layer of silicon dioxide (SiO₂) on the wafer's surface, which is critical for forming the gate insulator in transistors.

Annealing

Many fabrication steps, such as ion implantation (another doping method), cause damage to the semiconductor's crystal lattice. Annealing is a thermal process that repairs this damage.

By heating the wafer in a controlled furnace, atoms are given enough mobility to settle back into their proper lattice sites. This process also serves to electrically "activate" implanted dopants that were not initially part of the crystal structure.

Chemical Vapor Deposition (CVD)

A tube furnace can also act as a reactor for Chemical Vapor Deposition (CVD). In this process, precursor gases flow through the hot tube and react on the wafer's surface to deposit thin films of materials like polysilicon, silicon nitride, or other dielectrics.

Understanding the Trade-offs

While indispensable, the traditional tube furnace is not without its limitations, which have driven the development of alternative technologies.

Batch Processing vs. Turnaround Time

Horizontal and vertical tube furnaces are batch tools, meaning they process a large number of wafers at once. While efficient for mass production, this is slow for research and development, where quick iteration on a single wafer is often needed.

Thermal Budget

Every high-temperature step consumes a portion of the device's "thermal budget." Extended time at high temperatures can cause previously placed dopants to diffuse further than intended, potentially ruining the device structure. Managing this budget is a critical challenge.

Risk of Contamination

Because they are used for multiple processes, furnaces can be a source of cross-contamination if not meticulously cleaned and dedicated to specific materials. Purity is paramount in semiconductor fabrication, and any foreign atoms can be catastrophic.

Making the Right Choice for Your Goal

To apply these processes effectively, you must match the technique to your specific objective in modifying the material.

- If your primary focus is creating conductive pathways: Use the furnace for diffusion and doping to introduce and drive in impurity atoms, forming P-N junctions.

- If your primary focus is forming high-quality insulators: Use the furnace for thermal oxidation to grow a uniform silicon dioxide layer.

- If your primary focus is repairing crystal damage: Use the furnace for annealing to restore the lattice structure and activate dopants after processes like ion implantation.

- If your primary focus is adding a new material layer: Use the furnace as a CVD reactor to deposit thin films from precursor gases.

The tube furnace remains a foundational tool in materials research, providing the essential control over heat and chemistry needed to engineer the building blocks of modern electronics.

Summary Table:

| Application | Purpose | Key Process |

|---|---|---|

| Diffusion & Doping | Alter electrical conductivity | Introduce dopants into silicon |

| Oxidation | Grow insulating layers | Form silicon dioxide (SiO₂) |

| Annealing | Repair crystal damage | Activate dopants and restore lattice |

| CVD | Deposit thin films | React gases to add material layers |

Ready to elevate your electronic and semiconductor research with tailored thermal solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace options, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and innovation. Contact us today to discuss how our solutions can drive your success!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab