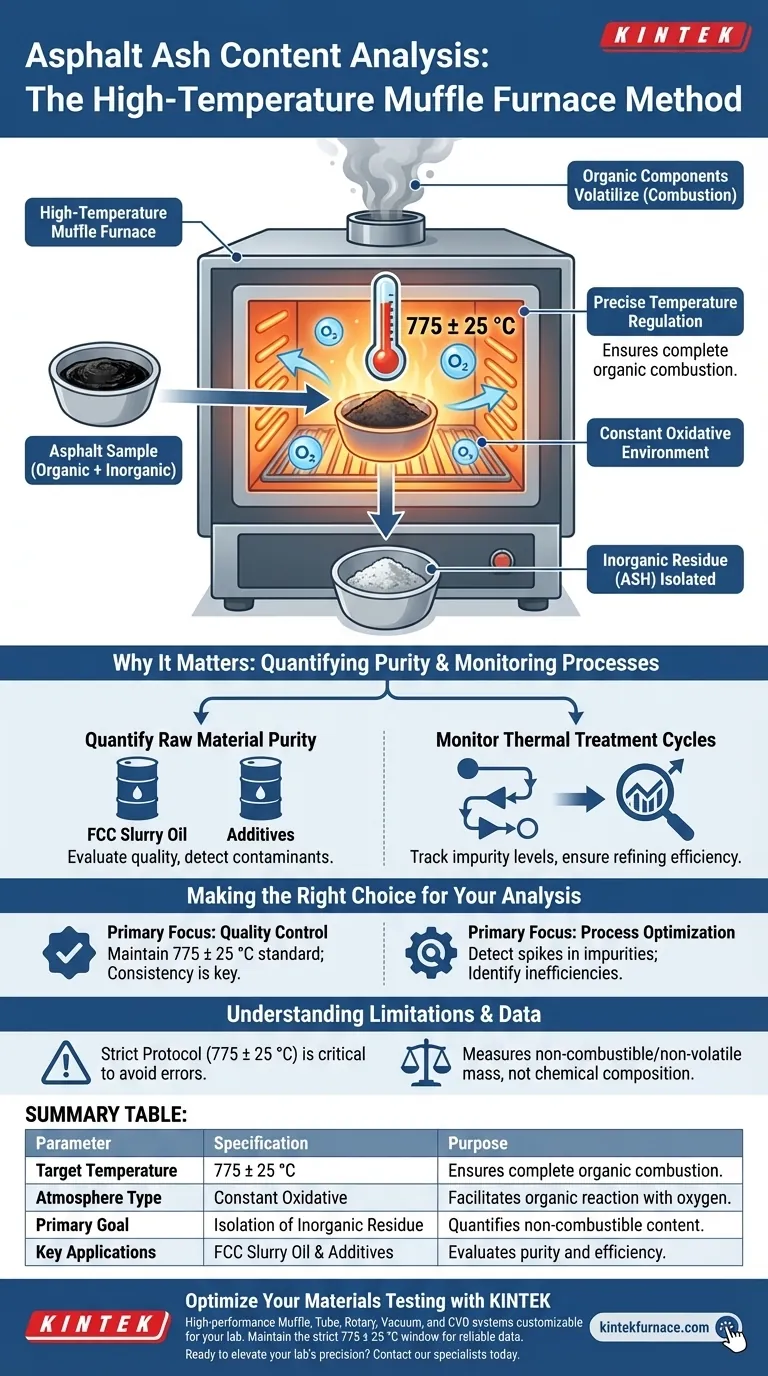

To determine the ash content of asphalt samples, a high-temperature muffle furnace is utilized to create a controlled, constant oxidative environment specifically at 775 ± 25 °C. This intense thermal treatment ensures the complete combustion of all organic components within the asphalt, leaving behind only the inorganic residues required for analysis.

The muffle furnace serves as a definitive separation tool, isolating non-combustible impurities from the organic hydrocarbon matrix to accurately quantify the purity of raw materials.

The Mechanics of Asphalt Ashing

Precise Temperature Regulation

The reliability of this method hinges on strict thermal control.

For asphalt specifically, the furnace must maintain a temperature of 775 ± 25 °C. This specific range is high enough to ensure total combustion of complex hydrocarbons but controlled enough to preserve the integrity of the inorganic residue.

Creating an Oxidative Environment

The muffle furnace is designed to provide a constant oxidative atmosphere.

As the asphalt sample is heated, the organic matter reacts with oxygen and volatilizes. This process continues until every trace of carbon-based material is consumed.

Isolation of Inorganic Residue

The ultimate goal of this thermal cycle is the isolation of "ash."

Once the organic components have been incinerated, only the inorganic residues remain. This residue represents the non-combustible mineral content of the original sample.

Why Asphalt Ash Content Matters

Quantifying Raw Material Purity

This method is essential for evaluating the quality of raw inputs.

It is particularly critical for analyzing materials like Fluid Catalytic Cracking (FCC) slurry oil and various asphalt additives. High ash content often indicates the presence of contaminants that could compromise the performance of the final product.

Monitoring Thermal Treatment Cycles

Beyond initial testing, this process enables continuous quality control.

Researchers use the data derived from ash content to monitor impurity levels throughout the entire thermal treatment cycle. This ensures that the refining or blending processes are functioning within specified parameters.

Understanding the Limitations

Strict Adherence to Protocol

The specific temperature window (775 ± 25 °C) is not a suggestion; it is a technical requirement.

Deviating from this range introduces error. Temperatures that are too low may result in incomplete combustion (false high ash), while excessive temperatures could volatize certain inorganic salts (false low ash).

Non-Volatile vs. Non-Combustible

It is important to distinguish what the furnace actually measures.

The furnace determines which parts of the sample are non-combustible and non-volatile at the set temperature. It does not identify the chemical composition of the ash, only its mass relative to the original sample.

Making the Right Choice for Your Analysis

To ensure your data is actionable, align your procedural focus with your specific analytical goals:

- If your primary focus is Quality Control: Ensure your furnace calibration is verified frequently to maintain the 775 ± 25 °C standard, as consistency is key for tracking FCC slurry oil purity.

- If your primary focus is Process Optimization: Use ash content data to detect spikes in impurities, which may indicate inefficiencies or contamination in your thermal treatment equipment.

By strictly controlling the oxidative environment, you transform a simple heating process into a critical diagnostic tool for asphalt integrity.

Summary Table:

| Parameter | Specification | Purpose in Asphalt Analysis |

|---|---|---|

| Target Temperature | 775 ± 25 °C | Ensures complete organic combustion without residue loss. |

| Atmosphere Type | Constant Oxidative | Facilitates reaction of organic matter with oxygen. |

| Primary Goal | Isolation of Inorganic Residue | Quantifies non-combustible mineral content and impurities. |

| Key Applications | FCC Slurry Oil & Additives | Evaluates raw material purity and refining efficiency. |

Optimize Your Materials Testing with KINTEK

Precise ash content analysis requires equipment that delivers absolute thermal stability. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs. Whether you are analyzing FCC slurry oil or perfecting asphalt additives, our furnaces ensure you maintain the strict 775 ± 25 °C window necessary for reliable data.

Ready to elevate your lab's precision? Contact our specialists today to find the perfect high-temperature solution for your application.

Visual Guide

References

- Mingzhi Wang, Xiaolong Zhou. The Neglected Role of Asphaltene in the Synthesis of Mesophase Pitch. DOI: 10.3390/molecules29071500

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-temperature muffle furnace facilitate the conversion of precursors? Unlock Peak Catalytic Performance

- How is a high-temperature box furnace utilized during the calcination and sintering stages of SrVO3 precursors?

- What should be considered when purchasing a box type electric furnace? Key Factors for Optimal Thermal Processing

- How is the chamber temperature displayed in the muffle furnace? Get Accurate Readings for Your Lab

- What is a muffle furnace and where is it commonly used? Essential for High-Temperature, Contamination-Free Heating

- How does the design of muffle furnaces contribute to the longevity of heating elements? Extend Lifespan with Protective Isolation

- What is the difference between electric oven and muffle furnace? Choose the Right Heating Tool for Your Lab

- What is the function of a high-temperature muffle furnace in the determination of ash and crude fiber? Expert Analysis