In short, a muffle furnace extends the life of its heating elements through a design centered on isolation. By placing the heating elements outside a separate inner chamber (the "muffle"), the furnace physically shields them from corrosive vapors, accidental contact, and the harsh chemical byproducts generated during high-temperature processes.

The core principle is protection through separation. The furnace's muffle acts as a barrier, safeguarding the delicate and expensive heating elements from the volatile environment inside the heating chamber, which directly translates to a longer operational lifespan and greater reliability.

The Core Principle: Isolation as Protection

A muffle furnace's longevity is not an accident; it is the direct result of a design that prioritizes the separation of the heat source from the material being heated.

The 'Muffle' as a Physical Shield

The defining feature is the muffle itself—an insulated inner chamber typically made of high-purity ceramic.

Heating elements are wound around the exterior of this chamber. They heat the muffle, which in turn radiates heat uniformly to the contents inside. This indirect heating method is fundamental to their protection.

Shielding from Corrosive Vapors and Gases

Many materials, when heated to high temperatures, release vapors or off-gas substances that are highly corrosive.

Direct exposure to these chemical agents would rapidly degrade the heating elements, causing them to become brittle and fail prematurely. The sealed muffle contains these byproducts, keeping the elements pristine.

Preventing Contamination and Physical Damage

Spills, splatters, or powders from the materials being processed can directly contact and damage exposed heating elements.

The muffle design makes this type of direct physical contamination impossible, preventing the short circuits or chemical reactions that would otherwise destroy the elements.

How Insulation Enhances Longevity and Efficiency

Beyond the muffle itself, the overall construction and insulation play a critical secondary role in extending the life of heating elements.

Reducing Thermal Stress with Stable Temperatures

Muffle furnaces use thick, high-quality ceramic fiber insulation to minimize heat loss. This creates a highly stable thermal environment.

This stability allows for controlled, gradual temperature changes. It avoids the rapid heating and cooling cycles—known as thermal shock—that are a primary cause of fatigue and eventual failure in all high-temperature heating elements.

Improving Efficiency to Reduce Workload

Superior insulation means the furnace retains heat extremely well. The heating elements do not need to cycle on and off as frequently to maintain a set temperature.

Fewer power cycles and a lower overall duty cycle reduce the cumulative wear and tear on the elements, contributing significantly to a longer operational life. This design makes the furnace both durable and energy-efficient.

Understanding the Key Trade-offs

While the design is highly effective, it's important to recognize its inherent characteristics and requirements.

Indirect Heating vs. Speed

The primary trade-off is heating speed. Because the heat must first transfer through the muffle wall before reaching the sample, the ramp-up time can be slightly slower than in furnaces with exposed elements.

However, this is a necessary compromise for the vast increase in element longevity, safety, and heating uniformity.

Element Materials Still Matter

The protective design benefits all types of heating elements, from standard wire and silicon carbide (SiC) rods to silicon molybdenum (MoSi2) rods.

Even with this protection, the choice of element material remains critical. Each has its own maximum temperature rating and chemical resistances that dictate its suitability for specific applications.

Design Does Not Eliminate Maintenance

A superior design reduces the rate of wear but does not eliminate it. Regular inspection of heating elements for signs of degradation, checking the integrity of the muffle chamber, and verifying temperature calibration remain essential for long-term performance.

Making the Right Choice for Your Goal

Understanding this design allows you to use the equipment more effectively and extend its life.

- If your primary focus is maximizing equipment lifespan: Run controlled, gradual heating and cooling cycles whenever possible to minimize thermal shock, even though the furnace is designed to manage it.

- If your primary focus is process purity: The muffle design is inherently superior, as it prevents byproducts from the heating elements (like dust from aging insulation) from contaminating your samples.

- If your primary focus is safety: The isolation of the electrical heating elements from the chamber interior dramatically reduces the risk of electrical faults or reactions with volatile samples.

By appreciating that a muffle furnace is engineered as a complete system, you can ensure its reliability for years to come.

Summary Table:

| Feature | Benefit for Heating Element Longevity |

|---|---|

| Muffle Chamber Isolation | Shields elements from corrosive vapors and physical damage |

| Indirect Heating | Reduces exposure to harsh chemical byproducts |

| High-Quality Insulation | Minimizes thermal stress and power cycling |

| Controlled Temperature Changes | Prevents thermal shock and element fatigue |

Maximize your lab's efficiency and equipment lifespan with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs. Contact us today to learn how our furnaces can enhance your processes and durability!

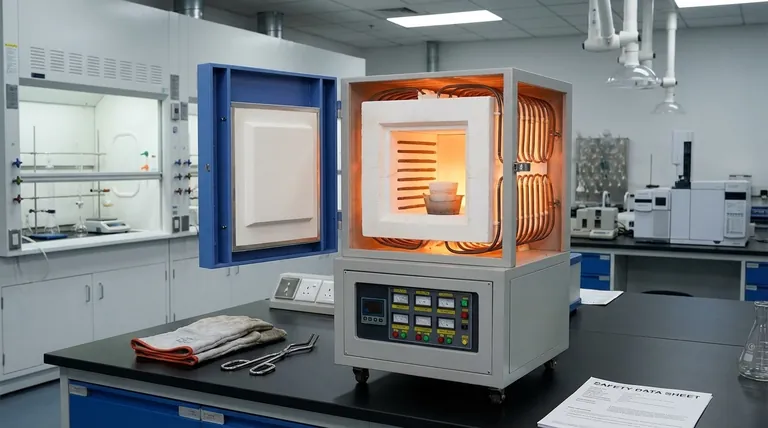

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure