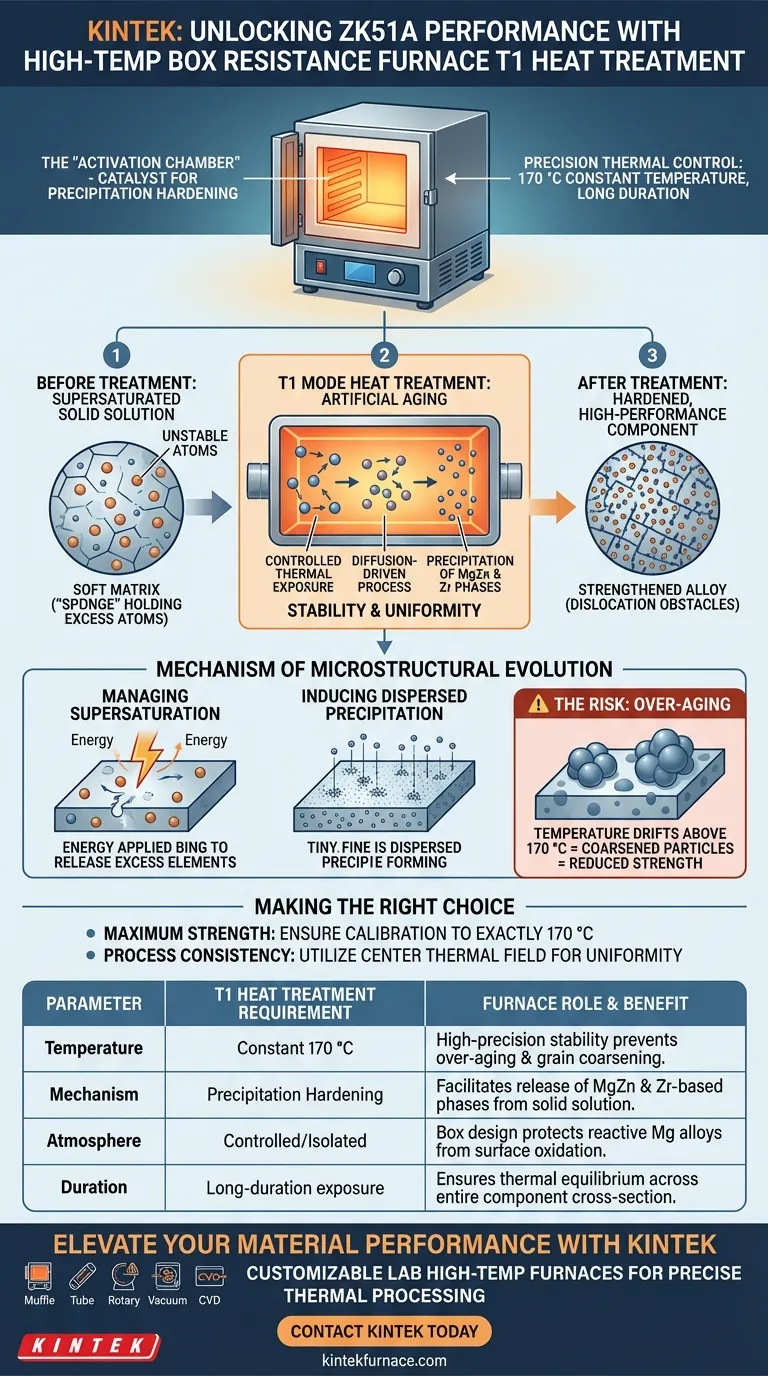

A high-temperature box resistance furnace serves as the critical "activation chamber" for ZK51A magnesium alloys during T1 mode heat treatment. Specifically, it provides a high-precision, constant temperature environment—typically around 170 °C—which is required to artificially age the alloy. This controlled thermal exposure transforms the material’s internal structure, turning a relatively soft matrix into a hardened, high-performance component.

The furnace functions as a catalyst for precipitation hardening, utilizing precise thermal field control to trigger the release of MgZn and Zr-based phases from a supersaturated solid solution, thereby significantly enhancing the alloy's mechanical properties.

The Role of Precision Thermal Control

The primary function of the muffle furnace in this context is not extreme heat, but extreme stability. While these furnaces are capable of reaching much higher temperatures for other applications (such as sintering ceramics or annealing steels), the T1 treatment of ZK51A requires a moderate, specific thermal window.

Establishing the Thermal Field

The furnace is set to a constant temperature, cited in your reference as 170 °C.

At this specific temperature, the thermal energy is sufficient to mobilize atoms within the alloy without causing melting or grain growth that would degrade performance.

Sustaining Long-Duration Exposure

T1 heat treatment is a diffusion-driven process, meaning it takes time.

The box resistance furnace maintains this 170 °C environment over a long duration. This stability ensures that the entire cross-section of the component reaches equilibrium, preventing thermal gradients that could lead to uneven material properties.

Mechanism of Microstructural Evolution

The "Deep Need" of using this furnace is to manipulate the microscopic architecture of the ZK51A alloy. The furnace acts as the tool to facilitate phase transformations that do not occur at room temperature.

Managing the Supersaturated Solid Solution

Before entering the furnace, the ZK51A alloy exists in a state of a "supersaturated solid solution."

Imagine a sponge holding more water than it naturally should; the alloy is holding more alloying elements in the solution than is stable. The furnace heat provides the activation energy needed to relieve this supersaturation in a controlled manner.

Inducing Dispersed Precipitation

The core objective of the heat treatment is the dispersed precipitation of MgZn (Magnesium-Zinc) and Zr-based (Zirconium) phases.

The furnace's steady heat forces these elements to precipitate out of the solid solution. These tiny, dispersed particles act as obstacles to dislocation movement within the metal's crystal lattice, which is the physical basis for precipitation hardening.

Understanding the Trade-offs

While the box resistance furnace is the ideal tool for this process, valid outcomes depend on understanding the limitations of the equipment and the process.

The Risk of Temperature Fluctuations

Precision is paramount; if the furnace drifts significantly above 170 °C, you risk "over-aging."

Over-aging causes the beneficial precipitates to coarsen (clump together). Instead of a fine mist of strengthening particles, you end up with large blobs that no longer effectively impede dislocations, reducing the alloy's strength.

Atmosphere and Surface Integrity

While the primary reference focuses on temperature, the supplementary references highlight that muffle furnaces often control atmosphere to prevent oxidation.

For Magnesium alloys like ZK51A, which are highly reactive, the "box" design of the furnace helps isolate the workload. However, at 170 °C, the risk of catastrophic oxidation is lower than at sintering temperatures, but maintaining a clean, stable environment remains a best practice to ensure surface quality.

Making the Right Choice for Your Goal

To maximize the utility of a box resistance furnace for ZK51A T1 treatment, align your operational parameters with your specific mechanical requirements.

- If your primary focus is Maximum Strength: Ensure the furnace controller is calibrated to hold exactly 170 °C with minimal fluctuation to maximize the density of fine MgZn precipitates.

- If your primary focus is Process Consistency: Utilize the center of the "box" or thermal field where the temperature is most uniform, avoiding placement near the door or heating elements to prevent uneven aging.

Ultimately, the muffle furnace is not just a heater, but a precision instrument used to "lock in" the mechanical potential of the ZK51A alloy through controlled artificial aging.

Summary Table:

| Parameter | T1 Heat Treatment Requirement | Furnace Role & Benefit |

|---|---|---|

| Temperature | Constant 170 °C | High-precision stability prevents over-aging and grain coarsening. |

| Mechanism | Precipitation Hardening | Facilitates the release of MgZn and Zr-based phases from solid solution. |

| Atmosphere | Controlled/Isolated | Box design protects reactive magnesium alloys from surface oxidation. |

| Duration | Long-duration exposure | Ensures thermal equilibrium across the entire component cross-section. |

Elevate Your Material Performance with KINTEK

Precision is the difference between a high-performance alloy and a failed component. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of magnesium alloy heat treatment.

Our lab high-temp furnaces are fully customizable to your unique thermal field requirements, ensuring the stability needed for perfect precipitation hardening.

Ready to optimize your thermal processing? Contact KINTEK today to consult with our experts!

Visual Guide

References

- Anastasia Akhmadieva, Alexander Vorozhtsov. Structure, Phase Composition, and Mechanical Properties of ZK51A Alloy with AlN Nanoparticles after Heat Treatment. DOI: 10.3390/met14010071

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature box resistance furnace synthesize WC/C@N-S nanocatalysts? Precision Thermal Control

- What role does a box muffle furnace play in the calcination of ZnO? Master Nanoparticle Crystal Engineering

- Why are electric furnaces considered a quieter heating option? Silent Operation Explained

- Why is atmosphere control important in a Muffle furnace, and what types of atmospheres can be used?

- What is the function of a laboratory muffle furnace in the carbonization process? Transform Waste into Nanosheets

- What is the role of muffle furnaces in incineration processes? Precision Ashing for Accurate Material Analysis

- How does an Electric Furnace facilitate defect repair in SiO2/Si interface structures during post-irradiation annealing?

- What is the role of a high-temperature muffle furnace in the annealing process of para-aramid fibers?