In the context of incineration, a muffle furnace serves a highly specialized and analytical purpose. Its role is the controlled, high-temperature combustion of small, precisely weighed samples to completely remove all organic material, leaving behind only the inorganic ash for quantitative analysis. This process, often called ashing, is critical in quality control and investigative fields like material science, forensics, and pharmaceuticals.

A muffle furnace's function in incineration is not about waste disposal but about analytical preparation. It uses uniform, high-temperature heating within an isolated chamber to transform a sample, ensuring the remaining ash is a pure, uncontaminated representation of its original inorganic content.

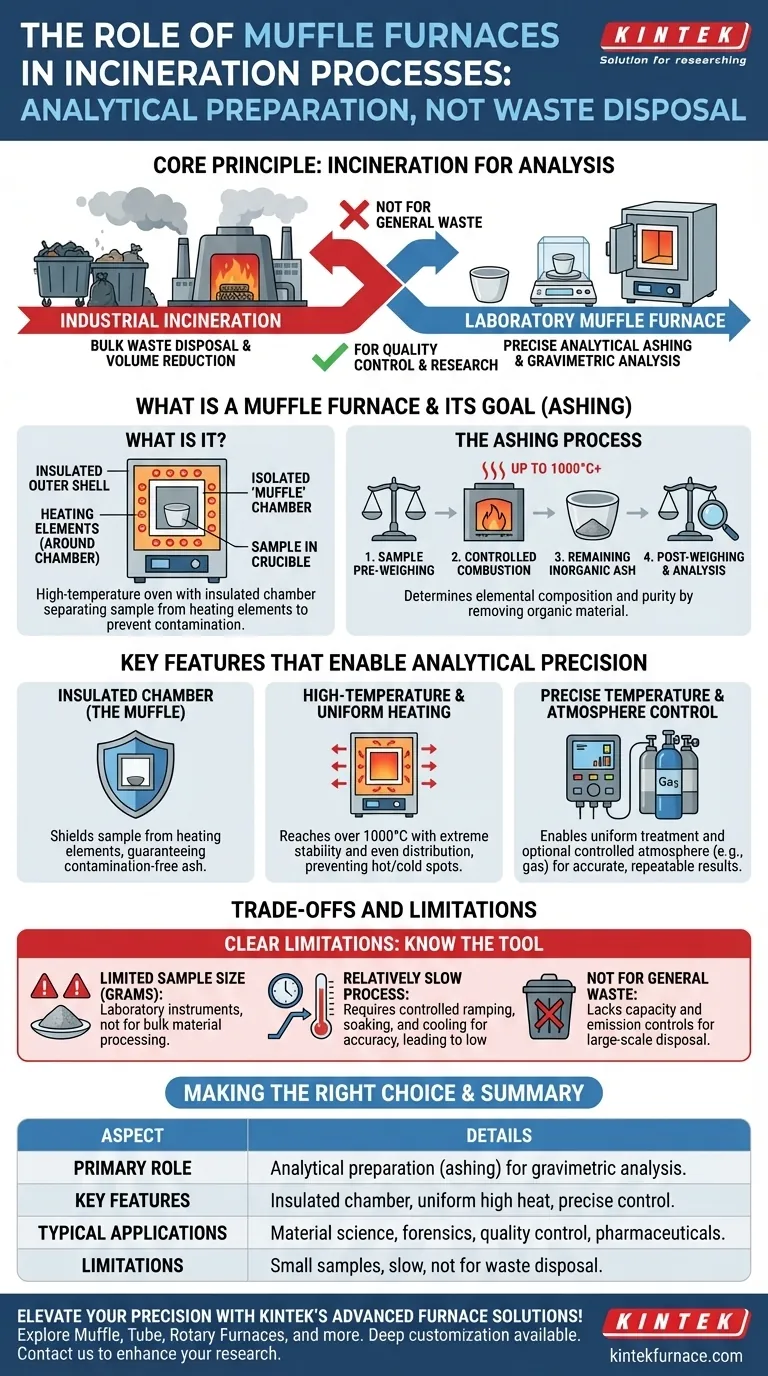

The Core Principle: Incineration for Analysis, Not Disposal

The term "incineration" can be misleading. In an industrial context, it means burning large volumes of waste. In a laboratory setting with a muffle furnace, it refers to a precise thermal decomposition technique.

What is a Muffle Furnace?

A muffle furnace is essentially a high-temperature oven. Its defining feature is an insulated inner chamber (the "muffle") that separates the sample from the heating elements.

This design prevents contamination from the combustion byproducts of a fuel source and ensures the sample is heated uniformly by convection and radiation.

The Goal of Ashing

The primary goal of using a muffle furnace for incineration is to perform gravimetric analysis. A sample is weighed before and after the ashing process.

The difference in weight reveals the percentage of organic or volatile content, while the remaining ash can be further analyzed to determine its elemental composition. This is crucial for verifying the purity of materials or identifying unknown substances.

Why Precision is Non-Negotiable

To get an accurate result, the process must be perfectly controlled. The temperature must be high enough to burn off all organic matter but not so high that it vaporizes or alters the inorganic compounds of interest.

A muffle furnace provides the precise temperature control and uniform heating needed to ensure the entire sample is treated identically, guaranteeing repeatable and reliable results.

Key Features That Enable Analytical Incineration

A muffle furnace is specifically engineered for this type of work. Its utility comes from a few core features that differentiate it from a simple oven or a large-scale incinerator.

The Insulated Chamber (The "Muffle")

The isolated chamber is the most critical feature. It shields the sample from direct contact with the heating elements, which could flake off and contaminate the ash.

This separation is what guarantees the final ash is purely derived from the original sample, which is essential for accurate analysis.

High-Temperature and Uniform Heating

Muffle furnaces are designed to reach and maintain very high temperatures, often exceeding 1000°C, with extreme stability.

Their internal construction ensures heat is distributed evenly throughout the chamber, preventing hot or cold spots that could lead to incomplete combustion in one part of the sample and volatilization in another.

Controlled Atmosphere Capabilities

Modern furnaces often allow for the introduction of specific gases, enabling a controlled atmosphere.

While not always required for simple ashing, this capability is vital for more advanced processes like annealing or sintering, where preventing oxidation is critical. It underscores the furnace's role as a high-precision instrument.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is a specialized tool with clear limitations. Understanding these is key to using it correctly.

Limited Sample Size

Muffle furnaces are designed for small samples, typically weighing only a few grams. They are laboratory instruments, not industrial processing equipment.

This makes them completely unsuitable for any form of bulk material disposal or large-scale incineration.

Relatively Slow Process Times

Achieving thermal uniformity and precise temperature control is not instantaneous. A typical ashing cycle involves slowly ramping the temperature up, letting it soak for several hours, and then slowly cooling it down.

This methodical pace is necessary for accuracy but makes it a low-throughput process.

Not Designed for General Waste

Using a muffle furnace for general waste is inefficient and inappropriate. It lacks the capacity for volume and the specialized emission controls (scrubbers) required for safely disposing of complex waste streams.

Making the Right Choice for Your Goal

Selecting the right thermal equipment depends entirely on your objective. The distinction between analytical ashing and waste disposal is the most important factor.

- If your primary focus is quantitative analysis of inorganic content: A muffle furnace is the correct tool, as it provides the contamination-free environment and precise temperature control needed for accurate ashing.

- If your primary focus is heat treatment or material modification: A muffle furnace is also ideal for processes like annealing, sintering, or hardening that require uniform heating and controlled temperature ramps.

- If your primary focus is large-scale waste disposal: A muffle furnace is entirely unsuitable; a dedicated industrial incinerator designed for high throughput and emissions compliance is required.

Understanding this distinction ensures you select the instrument that reliably achieves your specific scientific or industrial goal.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Role | Analytical preparation via ashing for gravimetric analysis of inorganic content |

| Key Features | Insulated chamber, uniform heating, precise temperature control, controlled atmosphere capabilities |

| Typical Applications | Material science, forensics, pharmaceuticals, quality control |

| Limitations | Small sample size, slow process times, not for waste disposal |

Elevate your laboratory's precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for accurate ashing and material analysis. Contact us today to discuss how our solutions can enhance your research and quality control processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing