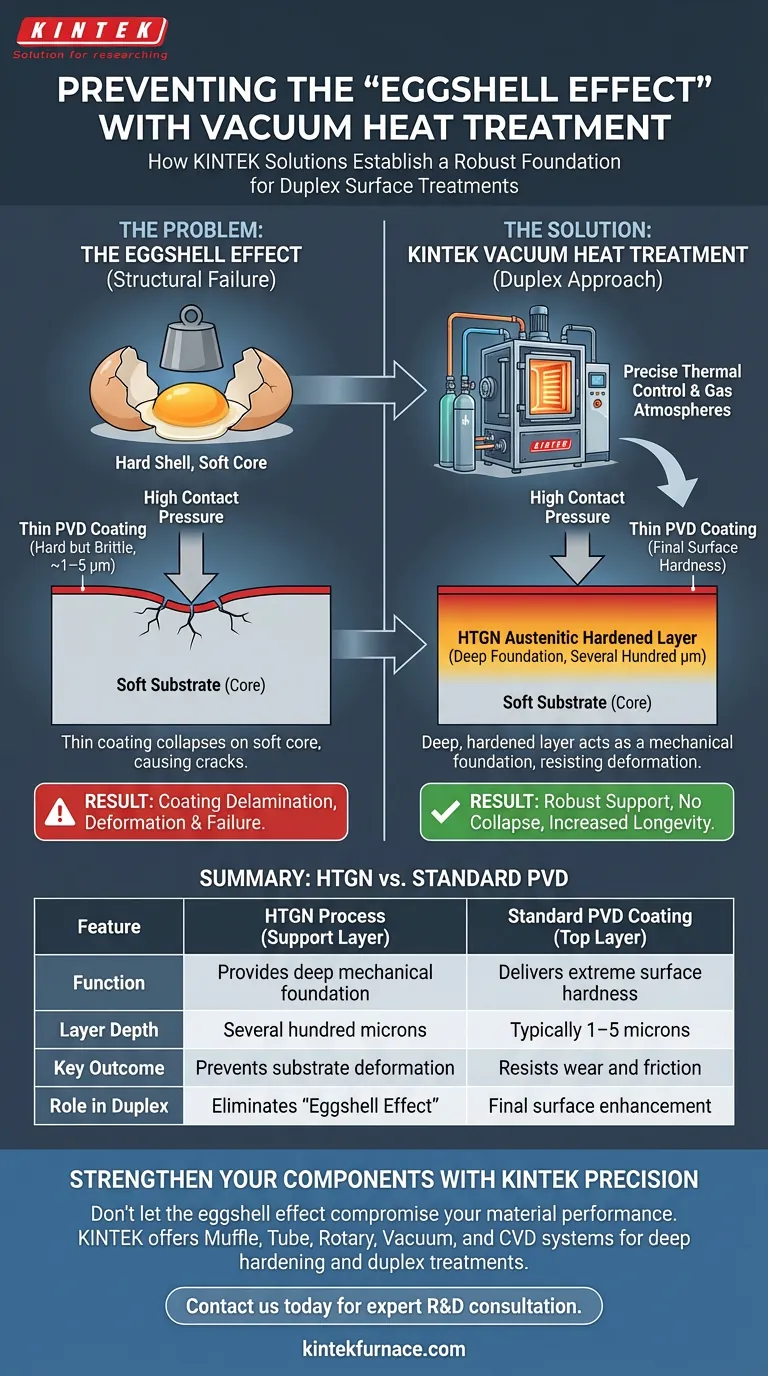

Vacuum heat treatment equipment prevents the eggshell effect by establishing a deep, hardened transition zone within the substrate material before a final coating is applied. Specifically, the equipment utilizes High-Temperature Gas Nitriding (HTGN) to create an austenitic hardened layer that is several hundred microns thick. This deep layer acts as a mechanical foundation, ensuring that thin, extremely hard outer coatings do not collapse or crack when subjected to high contact pressures.

Core Insight: The "eggshell effect" is a structural failure caused by placing a hard shell on a soft core. Vacuum heat treatment eliminates this by hardening the core first—specifically through HTGN—creating a robust, load-bearing foundation that supports the outer surface.

The Mechanics of the Solution

To understand how the equipment prevents failure, one must look at the specific processes it integrates. The vacuum environment allows for precise control over thermal conditions and gas atmospheres, enabling a "duplex" approach.

High-Temperature Gas Nitriding (HTGN)

The primary mechanism for prevention is the HTGN process.

This process introduces nitrogen into the surface of stainless steel at elevated temperatures.

Unlike standard surface coatings that simply sit on top, HTGN modifies the subsurface chemistry of the steel itself.

Creating the Austenitic Hardened Layer

The result of HTGN is the formation of an austenitic hardened layer.

According to technical specifications, this layer can be several hundred microns thick.

This depth is critical; it bridges the gap between the soft core material and the hard outer coating.

Providing Mechanical Support

Without this layer, a thin coating (like PVD) would behave like an eggshell—hard but brittle, resting on a soft interior.

When pressure is applied to untreated steel, the substrate deforms, causing the coating to crack.

The HTGN layer creates a robust mechanical foundation, resisting deformation and keeping the outer film intact.

Integration Capabilities

Vacuum heat treatment equipment is not limited to a single function. Its ability to prevent the eggshell effect relies on its versatility in combining processes.

Duplex Surface Treatment

The equipment facilitates duplex surface treatment, which combines the deep hardening of HTGN with surface finishing.

Following the creation of the support layer, the equipment can facilitate subsequent processes like Low-Temperature Plasma Nitriding (LTPN) or Physical Vapor Deposition (PVD).

Versatile Thermal Control

Beyond nitriding, this equipment is capable of performing nearly all heat treatment processes.

This includes quenching (gas, oil, or water), annealing, and tempering.

This versatility ensures that the core material retains its necessary bulk properties (like toughness) while the surface is engineered for extreme hardness.

Critical Considerations and Trade-offs

While vacuum heat treatment effectively solves the eggshell effect, it introduces specific complexities that must be managed.

Process Complexity

Implementing a duplex treatment (HTGN + PVD) is significantly more complex than a single-stage coating.

It requires precise thermal control to ensure the nitrogen diffuses correctly without compromising the corrosion resistance of the stainless steel.

Depth vs. Time

Achieving a hardened layer of several hundred microns takes time and energy.

There is a trade-off between the depth of the support layer (durability) and the processing time (cost/throughput).

Making the Right Choice for Your Project

When specifying surface treatments for high-load applications, consider the following regarding vacuum heat treatment:

- If your primary focus is heavy contact loading: Prioritize the HTGN process to ensure the hardened sub-layer is sufficiently deep (hundreds of microns) to support the topcoat.

- If your primary focus is versatility: Leverage the equipment's ability to switch between quenching, annealing, and nitriding to treat various components within the same facility.

- If your primary focus is preventing coating delamination: Ensure the process specification explicitly calls for a "duplex" approach to bridge the hardness gap between substrate and coating.

By securing the foundation first, vacuum heat treatment ensures your surface engineering delivers actual longevity rather than just temporary hardness.

Summary Table:

| Feature | HTGN Process (Support Layer) | Standard PVD Coating (Top Layer) |

|---|---|---|

| Function | Provides deep mechanical foundation | Delivers extreme surface hardness |

| Layer Depth | Several hundred microns | Typically 1–5 microns |

| Key Outcome | Prevents substrate deformation | Resists wear and friction |

| Role in Duplex | Eliminates "Eggshell Effect" | Final surface enhancement |

Strengthen Your Components with KINTEK Precision

Don't let the "eggshell effect" compromise your material performance. KINTEK provides industry-leading vacuum heat treatment solutions designed to build robust foundations for your most demanding applications.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to implement HTGN for deep hardening or require a fully customizable high-temperature furnace for unique duplex treatments, our systems ensure precise thermal control and superior mechanical support for your target products.

Ready to optimize your surface engineering? Contact us today to consult with our experts and find the perfect furnace for your laboratory or industrial needs.

Visual Guide

References

- André Paulo Tschiptschin. PROCESSOS SOB VÁCUO USADOS PARA TRATAMENTOS TÉRMICOS E DE SUPERFÍCIE DE AÇOS E LIGAS ESPECIAIS. DOI: 10.17563/rbav.v43i1.1262

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the advantages of using a vacuum brazing furnace? Achieve Clean, Strong, and Flux-Free Joints

- How do continuous vacuum furnaces support high-precision welding and joining of metal materials? Achieve Clean, Strong Bonds with Precision Control

- What is the process of vacuum tempering? Achieve Bright, Oxide-Free Parts with Superior Toughness

- What are the advantages of vacuum carburizing over conventional atmosphere-carburizing methods? Boost Quality and Efficiency in Case Hardening

- How does a vacuum furnace prevent oxidation of metals? Unlock Purity and Strength in Heat Treatment

- How does the vacuum furnace improve the performance of heat-treated products? Achieve Superior Control and Quality

- How does the vacuum pumping system in a vertical vacuum furnace operate? Learn the Multi-Stage Process for Precision

- Why is vacuum degassing equipment utilized in the preparation of low-alloy fire-resistant steel? | KINTEK Solutions