To achieve high-precision joining, continuous vacuum furnaces create a highly controlled, oxygen-free environment for heating metal components. This process prevents oxidation and contamination at the joint interface, significantly reduces thermal stress and material deformation, and results in exceptionally clean, strong, and dimensionally accurate bonds.

The core value of a vacuum furnace is not just the heat it provides, but the control it offers over the material's environment. By removing atmospheric gases, it eliminates the chemical reactions—like oxidation—that weaken joints, allowing for welded connections that are as pure and strong as the base materials themselves.

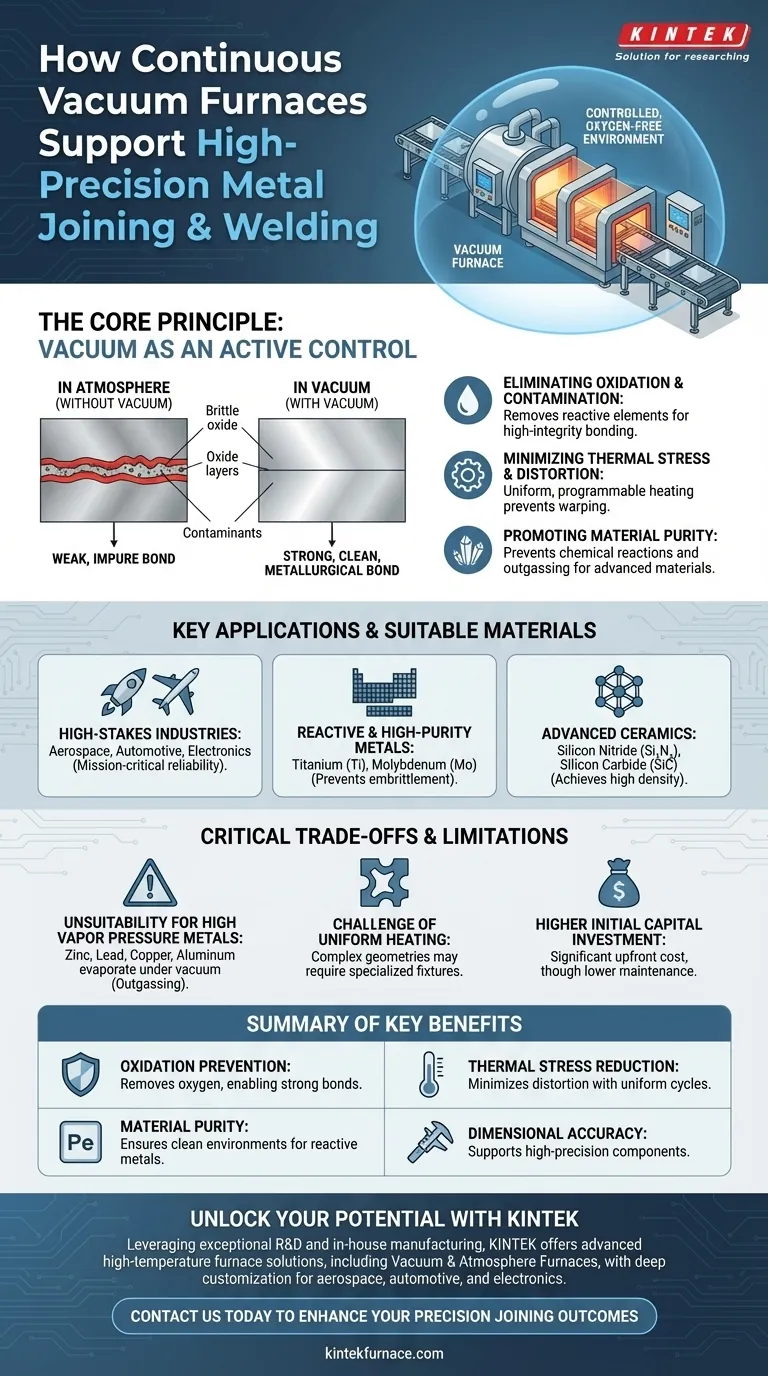

The Core Principle: Why a Vacuum Is a Game-Changer

A vacuum is not an empty space; it is an active engineering control. In the context of welding and joining, its primary function is to remove reactive elements that compromise the integrity of the final product.

Eliminating Oxidation and Contamination

When metals are heated in the presence of air, their surfaces rapidly form brittle oxides. These oxide layers prevent a strong metallurgical bond from forming, creating weak points and potential failure sites in the joint.

A vacuum furnace removes virtually all oxygen and other atmospheric contaminants. This ensures that the metal surfaces remain perfectly clean during the heating cycle, allowing for direct, high-integrity bonding.

Minimizing Thermal Stress and Distortion

Rapid or uneven heating and cooling introduce internal stresses into materials, causing them to warp, crack, or deform. This is a critical problem for precision components with tight dimensional tolerances.

Continuous vacuum furnaces provide highly uniform, programmable heating and cooling cycles. This controlled thermal management minimizes temperature gradients across the part, drastically reducing internal stress and preserving the component's precise geometry.

Promoting Material Purity and Growth

The high-vacuum environment is ideal for preparing and processing advanced materials. It promotes the formation of dense, pure material structures by preventing unwanted chemical reactions and outgassing impurities from the metal itself.

This is critical for applications like joining high-purity titanium or sintering advanced ceramics, where even trace amounts of contamination can degrade mechanical or electrical properties.

Key Applications and Suitable Materials

The benefits of vacuum furnace joining make it indispensable in industries where performance and reliability are non-negotiable.

High-Stakes Industries

Industries like aerospace, automotive, and electronics rely on this technology for mission-critical components. The exceptional reliability of vacuum-brazed or welded joints is essential for parts that must withstand extreme temperatures, pressures, and vibrations.

Reactive and High-Purity Metals

Materials like titanium (Ti) and molybdenum (Mo) are highly reactive with oxygen, especially at elevated temperatures. A vacuum environment is the only way to join these materials without causing embrittlement or compromising their inherent properties.

Advanced Ceramics and Composites

Vacuum furnaces are used for sintering advanced ceramics like silicon nitride (Si₃N₄) and silicon carbide (SiC). The vacuum helps achieve near-theoretical density by reducing porosity, which dramatically increases the material's strength and thermal resistance for use in extreme environments.

Understanding the Critical Trade-offs

While powerful, vacuum furnace technology is not a universal solution. Understanding its limitations is key to successful implementation.

Unsuitability for High Vapor Pressure Metals

A significant limitation is the furnace's incompatibility with metals that have a high saturated vapor pressure. Materials like zinc, lead, manganese, copper, and aluminum can evaporate or "boil off" under a high vacuum at elevated temperatures.

This phenomenon, known as outgassing, can alter the surface composition of the workpiece and contaminate the furnace interior.

The Challenge of Uniform Heating

Achieving perfectly uniform temperature across large or geometrically complex workpieces can be difficult. It often requires the design of specialized fixtures and tooling to hold the parts and ensure even heat distribution, adding complexity and cost to the process.

The Cost-Benefit Equation

While vacuum furnaces often require less maintenance than traditional atmosphere furnaces and extend the lifespan of treated parts, the initial capital investment is significant. The long-term cost benefits must be weighed against this upfront expenditure.

Making the Right Choice for Your Application

Selecting the right joining technology depends entirely on your material, performance requirements, and production goals.

- If your primary focus is joining reactive materials like titanium: A vacuum furnace is non-negotiable to prevent embrittlement and preserve material properties.

- If your primary focus is achieving maximum joint strength and purity: The controlled vacuum environment is superior for eliminating the microscopic oxides that weaken traditional welds.

- If your primary focus is dimensional stability for precision components: The slow, uniform heating and cooling cycles offered by a vacuum furnace are essential to minimize distortion.

- If your primary focus is joining materials with high vapor pressure (like brass or certain aluminum alloys): A vacuum furnace is likely unsuitable, and alternative methods like controlled atmosphere brazing should be considered.

Ultimately, a continuous vacuum furnace empowers you to control the very chemistry of the joining process, ensuring the final product meets the most demanding specifications.

Summary Table:

| Key Benefit | Description |

|---|---|

| Oxidation Prevention | Removes oxygen to eliminate contamination, enabling strong metallurgical bonds. |

| Thermal Stress Reduction | Provides uniform heating and cooling to minimize distortion and preserve geometry. |

| Material Purity | Ensures clean environments for reactive metals like titanium and advanced ceramics. |

| Dimensional Accuracy | Supports high-precision components by reducing internal stresses and warping. |

Unlock the full potential of your metal joining processes with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior performance for industries like aerospace, automotive, and electronics. Contact us today to discuss how we can enhance your precision welding and joining outcomes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes