At its core, a vacuum furnace improves product performance by creating a pristine, highly controlled environment. By removing reactive gases like oxygen, the furnace prevents undesirable surface reactions while its advanced controls allow for unmatched thermal precision. This results in components with superior mechanical properties, a clean finish, and exceptional consistency compared to parts from conventional heat treatment methods.

A vacuum furnace is less a simple oven and more a comprehensive material processing system. By removing the variable of atmospheric interaction, it provides unparalleled control over a part's surface chemistry and internal microstructure, directly translating to enhanced strength, durability, and finish.

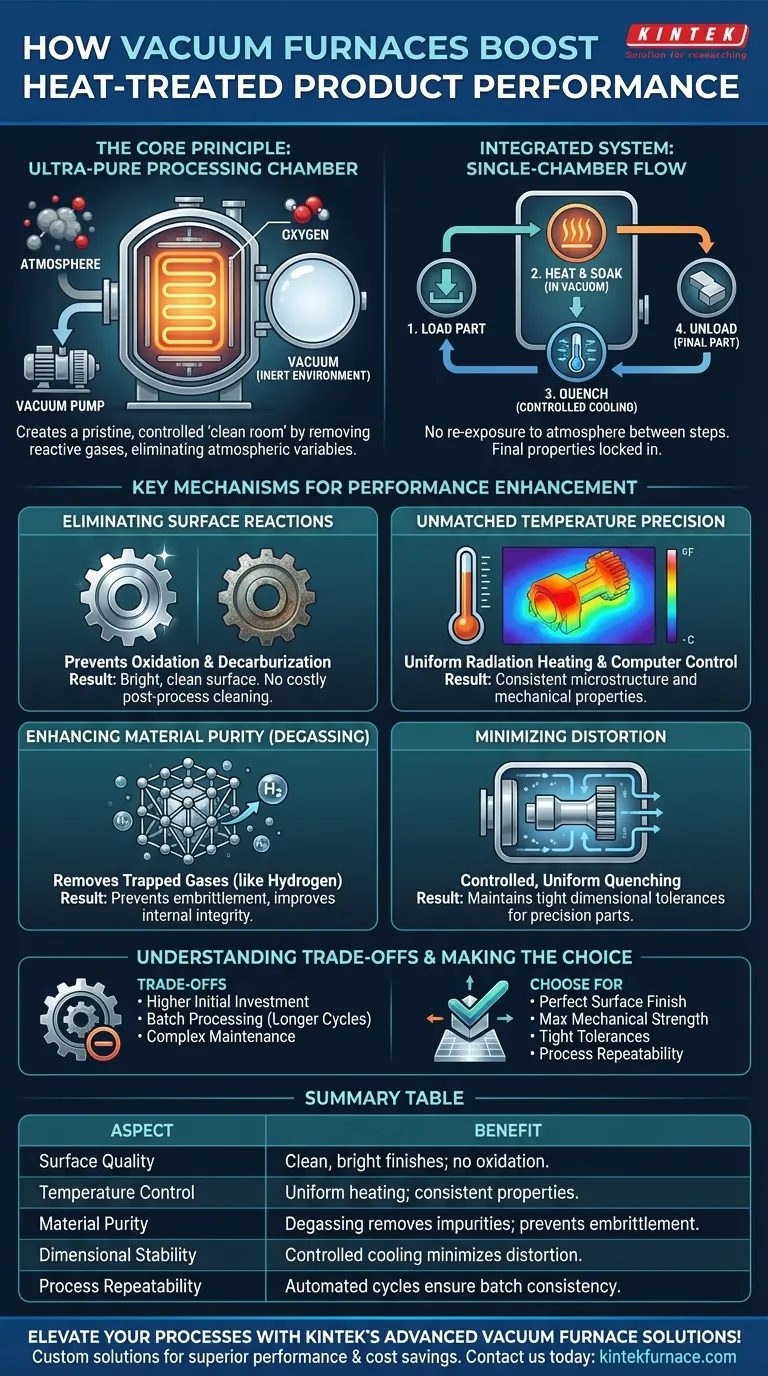

The Core Principle: An Ultra-Pure Processing Chamber

What "Vacuum" Means for Heat Treatment

The term "vacuum" refers to the removal of atmosphere from the heating chamber, specifically reactive gases like oxygen. This creates a stable, inert environment—effectively a "clean room" for metal components.

This controlled environment is the foundation for all the performance benefits. By eliminating atmospheric variables, the process becomes entirely predictable and focused on the interaction between heat and the material itself.

From Single Process to Integrated System

Modern vacuum furnaces are all-in-one systems. The heating, soaking, and quenching (rapid cooling) stages all occur within the single, sealed chamber.

This integration prevents any re-exposure to atmosphere between critical steps. The part goes in, undergoes the entire thermal cycle in a pure environment, and comes out with its final properties locked in, free from contamination.

Key Mechanisms for Performance Enhancement

Eliminating Surface Reactions: Oxidation and Decarburization

In a conventional furnace, the high heat and oxygen cause oxidation (scaling) and decarburization (the loss of carbon from the steel's surface), both of which degrade the part.

A vacuum furnace completely prevents these reactions. The result is a part with a bright, clean surface right out of the furnace, with no weakened or "metamorphic" layer. This often eliminates the need for costly secondary operations like grinding or chemical cleaning.

Achieving Unmatched Temperature Precision and Uniformity

Heating in a vacuum occurs primarily through radiation, which provides exceptionally uniform temperature distribution. Every surface of the part, no matter how complex its geometry, receives the same amount of thermal energy.

Combined with sophisticated computer controls, this allows for highly precise and repeatable thermal profiles. This consistency ensures that the desired microstructure and mechanical properties are achieved reliably across the entire part and from batch to batch.

Enhancing Material Purity Through Degassing

The vacuum environment actively pulls trapped contaminants, such as hydrogen and other unwanted gases, out of the metal itself. This process is known as degassing.

By removing these impurities, the furnace improves the material's internal integrity. A key benefit is the prevention of hydrogen embrittlement, a common cause of premature failure in high-strength components.

Minimizing Distortion with Controlled Cooling

After heating, parts are rapidly cooled (quenched) to achieve hardness. Vacuum furnaces use controlled backfills of inert gas (like nitrogen or argon) or integrated oil baths for this step.

This method provides a fast but highly uniform cooling rate, which drastically reduces the thermal stress that causes warping and distortion. This allows parts to maintain tight dimensional tolerances, which is critical for precision components.

Understanding the Trade-offs

Higher Initial Investment

Vacuum furnaces are complex, integrated systems. The initial capital cost is significantly higher than for a conventional atmosphere furnace due to the need for a vacuum-tight chamber, pumping systems, and sophisticated computer controls.

Batch Processing and Cycle Times

The process of pumping the chamber down to a vacuum, running the heating cycle, and cooling means that vacuum furnaces operate in batches. This can lead to longer overall cycle times compared to continuous-type furnaces used in some mass-production scenarios.

Maintenance Complexity

The high-tech nature of a vacuum furnace demands a higher level of maintenance. Servicing vacuum pumps, checking seals, and calibrating control systems requires specialized knowledge and can lead to higher operational overhead compared to simpler equipment.

Making the Right Choice for Your Application

Choosing the right heat treatment method depends entirely on your product's performance requirements and your manufacturing goals.

- If your primary focus is a perfect surface finish: A vacuum furnace is ideal, as it eliminates the oxidation that requires post-process cleaning or grinding.

- If your primary focus is maximizing mechanical strength and fatigue life: The combination of precise temperature control and degassing in a vacuum delivers superior, consistent microstructures.

- If your primary focus is maintaining tight dimensional tolerances: The controlled, uniform cooling of a vacuum furnace minimizes warping and distortion, especially in complex or thin-walled parts.

- If your primary focus is process repeatability for high-value components: The automated and programmable nature of vacuum furnaces ensures every batch is treated identically, leading to a high pass rate.

Ultimately, choosing a vacuum furnace is an investment in unparalleled control, yielding a final product with predictable and superior performance.

Summary Table:

| Aspect | Benefit |

|---|---|

| Surface Quality | Prevents oxidation and decarburization, resulting in clean, bright finishes without secondary processing. |

| Temperature Control | Ensures uniform heating and precise thermal profiles for consistent microstructure and mechanical properties. |

| Material Purity | Removes trapped gases through degassing, reducing hydrogen embrittlement and enhancing internal integrity. |

| Dimensional Stability | Minimizes distortion with controlled cooling, maintaining tight tolerances for precision components. |

| Process Repeatability | Provides automated, reliable cycles for high-value parts, ensuring batch-to-batch consistency. |

Elevate your heat treatment processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering superior performance, enhanced durability, and cost savings. Ready to transform your lab's efficiency and product quality? Contact us today to discuss how our tailored solutions can benefit your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion