Using gaskets or shims to elevate a workpiece is a highly effective thermal management strategy. By physically lifting the material off the furnace floor, you disrupt the conductive heat path to the insulation layer. This adjustment minimizes heat loss, resulting in a higher overall workpiece temperature and a significantly more uniform thermal environment.

The furnace floor often acts as a heat sink, draining energy from the bottom of your material through direct contact. Elevating the workpiece increases thermal resistance at this interface, forcing heat to remain within the part to ensure consistent sintering.

The Mechanics of Thermal Resistance

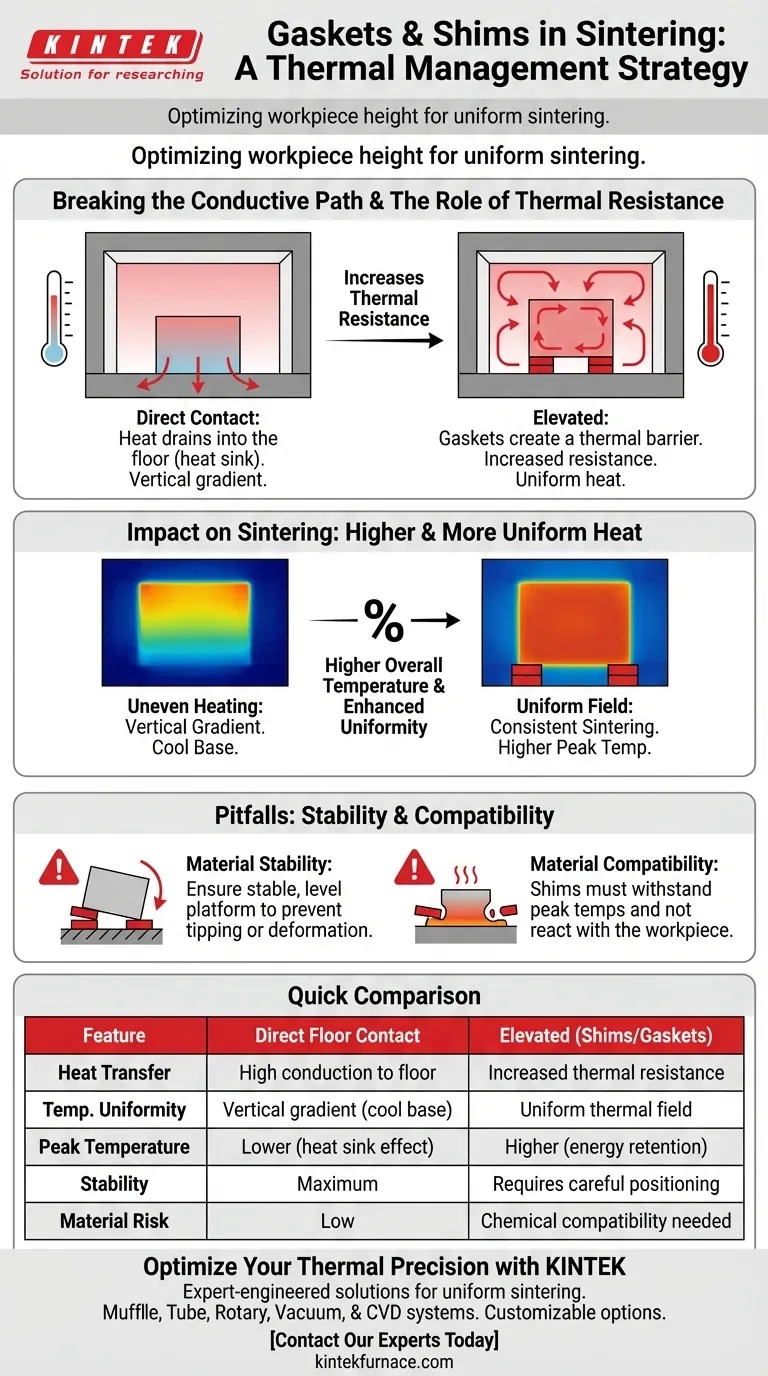

Breaking the Conductive Path

When a workpiece sits directly on the furnace floor, heat naturally flows from the hot material into the underlying insulation layer. This process is driven by thermal conduction.

By placing gaskets or shims under the workpiece, you introduce a physical gap. This separation acts as a barrier, drastically reducing the efficiency of that conductive heat transfer.

The Role of Thermal Resistance

The core principle at work here is thermal resistance. The gaskets modify the interface between the workpiece and the environment.

Increasing this resistance prevents the "bleeding" of heat into the external environment (the floor). This ensures that the energy generated by the furnace is utilized to heat the workpiece, rather than being lost to the structural insulation.

Impact on Temperature Dynamics

Increasing Overall Temperature

Because less heat is escaping through the bottom of the workpiece, the material retains more thermal energy.

Consequently, for the same furnace setting, an elevated workpiece will reach a higher actual temperature than one resting directly on the floor. This is critical for processes that require precise high-temperature thresholds.

Enhancing Temperature Uniformity

A common failure point in sintering is a vertical temperature gradient, where the top of the piece is hot and the bottom is cooler due to floor contact.

By increasing the thermal resistance at the bottom, you equalize the heat loss across the workpiece surfaces. This results in a uniform temperature field, which is essential for consistent material properties and preventing warping.

Common Pitfalls to Avoid

Material Stability

While elevating the workpiece improves thermal dynamics, it introduces mechanical instability.

You must ensure that the shims or gaskets are arranged to provide a stable platform. A workpiece that shifts or tips during the sintering process can result in deformation or uneven heating.

Material Compatibility

The gaskets or shims themselves become part of the thermal system.

They must be composed of materials capable of withstanding the peak sintering temperatures without melting, degrading, or chemically reacting with your workpiece.

Optimizing Your Furnace Setup

To get the most out of your sintering process, align your setup with your specific thermal goals.

- If your primary focus is temperature uniformity: Elevate the workpiece to minimize the vertical temperature gradient and prevent bottom-side cooling.

- If your primary focus is energy efficiency: Use this technique to stop the insulation layer from acting as a parasitic heat sink, ensuring maximum heat retention within the material.

Controlling the interface between your workpiece and the furnace floor is a simple, high-impact adjustment that directly correlates to higher-quality sintering results.

Summary Table:

| Feature | Direct Floor Contact | Elevated (Shims/Gaskets) | Impact on Sintering |

|---|---|---|---|

| Heat Transfer | High conduction to floor | Increased thermal resistance | Prevents heat "bleeding" |

| Temp. Uniformity | Vertical gradient (cool base) | Uniform thermal field | Ensures consistent material density |

| Peak Temperature | Lower (due to heat sink) | Higher (energy retention) | Faster, more reliable reaching of thresholds |

| Stability | Maximum | Requires careful positioning | Prevents deformation or tipping |

| Material Risk | Low | Chemical compatibility needed | Prevents contamination or melting |

Optimize Your Thermal Precision with KINTEK

Achieving uniform sintering requires more than just high temperatures; it demands precise control over every thermal interface. KINTEK provides the expert-engineered solutions you need to eliminate heat sinks and ensure material consistency.

Backed by industry-leading R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or a fully customizable system tailored to your unique workpiece geometry and thermal requirements, KINTEK is your partner in excellence.

Ready to elevate your sintering results? Contact our technical experts today to find the perfect furnace configuration for your lab.

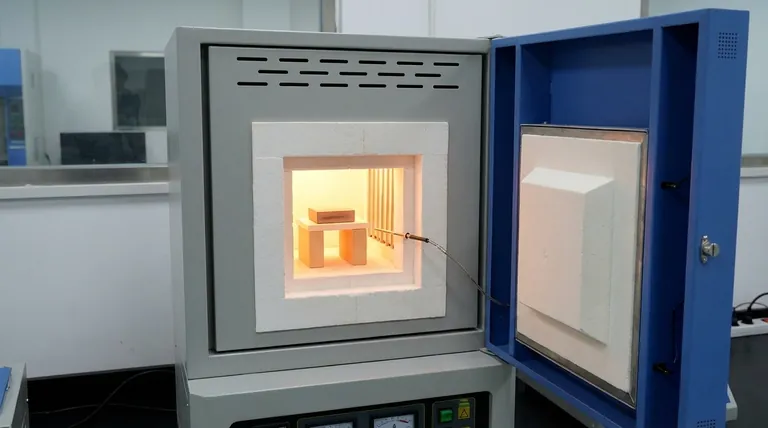

Visual Guide

References

- Yuchen Wang, Haisheng Fang. Research and optimization of temperature uniformity of high-precision muffle furnace. DOI: 10.1088/1742-6596/3009/1/012076

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are muffle furnaces and their primary uses? Essential for Contamination-Free Heating

- What role does a high-temperature muffle furnace play in the pre-calcination of PZT ceramics? Essential Synthesis Guide

- What industrial applications use muffle furnaces? Essential for Clean, High-Temp Processes

- What is the primary function of a high-temperature muffle furnace in LFP regeneration? Restore Battery Life with Precision

- What is the significance of using a muffle furnace to determine the ash content of biochar? Master Material Performance

- When is a muffle furnace typically used? Essential for Clean, High-Temperature Processes

- What is the mechanism of a high-temperature furnace in Bi-2223 sintering? Achieve Precision Phase Transformation

- What are the common uses of muffle furnaces? Essential for Material Analysis, Heat Treatment, and Synthesis