A muffle furnace is used for any high-temperature process that requires a highly controlled, uniform, and isolated heating environment. It is the standard tool for applications like ashing materials to determine their inorganic content, heat-treating metals without contamination, and testing material durability under extreme temperatures.

The core purpose of a muffle furnace is not just to generate high heat, but to provide clean high heat. Its defining feature—the "muffle"—is an insulated inner chamber that separates the material being heated from the raw heating elements, preventing contamination and ensuring precise, uniform temperature.

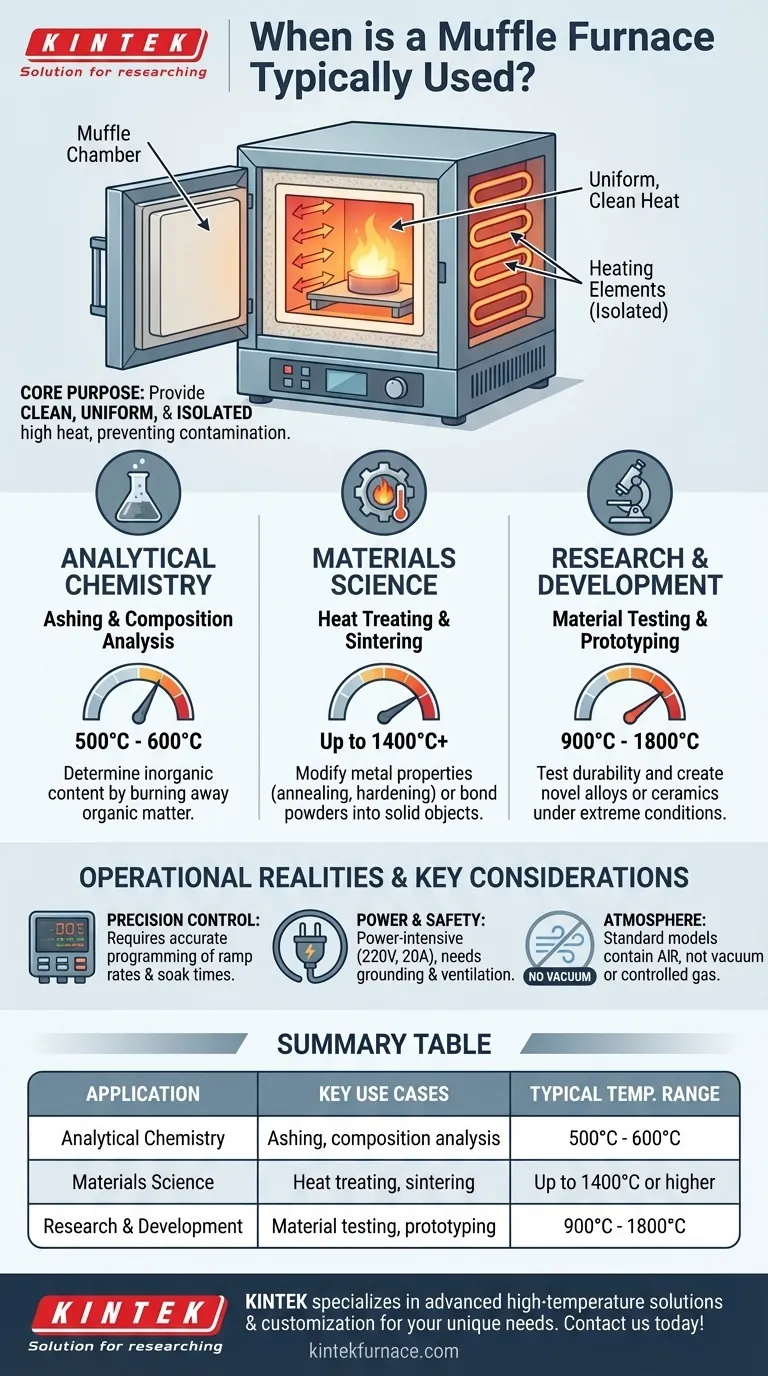

What Defines a Muffle Furnace?

A muffle furnace is essentially a high-temperature oven with a critical design feature that distinguishes it from a simple kiln or forge. Understanding its construction clarifies its purpose.

The Core Principle: The "Muffle"

The term muffle refers to the inner chamber that encloses the sample. This chamber acts as a barrier, isolating the workload from the direct radiation and potential byproducts of the heating elements.

This separation is the key to preventing contamination from combustion gases or flaking from the elements themselves.

Key Components and Construction

A typical lab-scale furnace consists of a few primary parts. The inner chamber (the muffle) is made of high-purity ceramic or alumina fiber to withstand extreme temperatures.

This chamber is surrounded by high-grade insulation, like fire bricks, which is then enclosed by an outer steel body. Kanthal or nickel-chromium wire heating elements are positioned around the muffle to provide even, radiant heat.

Temperature Control and Range

Muffle furnaces offer precise digital temperature control, often with an accuracy of ±5°C. They can operate across a wide spectrum, with standard laboratory models reaching 900°C to 1400°C and specialized units exceeding 1800°C.

Sensors, typically J-type or K-type thermocouples, provide real-time feedback to the controller to maintain a stable and accurate internal temperature.

Primary Applications in Science and Industry

The furnace's ability to deliver clean, uniform heat makes it indispensable across several fields. The applications can be grouped into three main categories.

For Analytical Chemistry: Ashing and Composition Analysis

Ashing is the most common laboratory use for a muffle furnace. This process involves heating a sample at high temperatures (typically 500-600°C) to completely burn away all organic matter.

The remaining non-combustible material, or ash, can then be weighed or analyzed to determine the inorganic content of the original sample. This is critical for quality control in food, pharmaceutical, and environmental testing.

Other analytical uses include determining volatile matter, analyzing moisture content, and preparing samples for elemental analysis.

For Materials Science: Heat Treating and Sintering

In metallurgy and materials science, muffle furnaces are used for various heat treatments. Processes like annealing, hardening, and tempering modify the microstructure and physical properties of metals. The controlled environment prevents oxidation and surface contamination.

Sintering is another key application. This involves heating compacted powders (ceramic or metallic) to just below their melting point, causing the particles to bond and form a solid, dense object.

For Research and Development: Material Testing

Engineers and scientists use muffle furnaces to test the thermal durability of components, create novel alloys, develop new types of glass, and prototype ceramic parts.

The furnace provides the repeatable, high-temperature environment needed to research material behavior under extreme conditions.

Understanding the Operational Realities

While powerful, a muffle furnace is a specialized piece of equipment that requires careful operation and understanding of its limitations.

The Need for Precise Control

The benefit of a muffle furnace is its precision, but this demands correct programming. Users must understand the required temperature ramp rates, soak times, and cooling profiles for their specific material to avoid thermal shock or incomplete processing.

Power and Safety Requirements

These are power-intensive devices. A typical benchtop model requires a dedicated 220V, 20A circuit to operate safely without overloading the system.

Proper grounding is non-negotiable to prevent electric shock, and the area must be well-ventilated, as some processes can release hazardous fumes.

Limitations on Atmosphere

While a standard muffle furnace protects from contamination from the heating elements, it does not create a vacuum or actively control the gas inside. The atmosphere is simply air.

For processes requiring a specific inert gas (like argon) or a reactive atmosphere, a specialized furnace with gas-purging capabilities is necessary.

Making the Right Choice for Your Process

Use this guide to determine if a muffle furnace fits your objective.

- If your primary focus is determining the inorganic content of a sample: A muffle furnace is the standard and necessary tool for ashing procedures.

- If your primary focus is altering the properties of a metal without surface oxidation: Use a muffle furnace for clean heat treatments like annealing or hardening in an air atmosphere.

- If your primary focus is creating new ceramic or powdered metal parts: A muffle furnace provides the uniform, high heat essential for successful sintering.

- If your primary focus requires a specific gas environment (e.g., nitrogen or argon): You need a specialized tube furnace or vacuum furnace, not a standard muffle furnace.

Ultimately, a muffle furnace is the definitive tool when your goal is to apply precise, uniform, and uncontaminated heat to a material.

Summary Table:

| Application | Key Use Cases | Typical Temperature Range |

|---|---|---|

| Analytical Chemistry | Ashing, composition analysis | 500°C - 600°C |

| Materials Science | Heat treating, sintering | Up to 1400°C or higher |

| Research & Development | Material testing, prototyping | 900°C - 1800°C |

Ready to enhance your lab's capabilities with reliable high-temperature solutions? KINTEK specializes in advanced muffle furnaces and other high-temperature systems like Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our solutions can deliver precise, contamination-free heating for your applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure