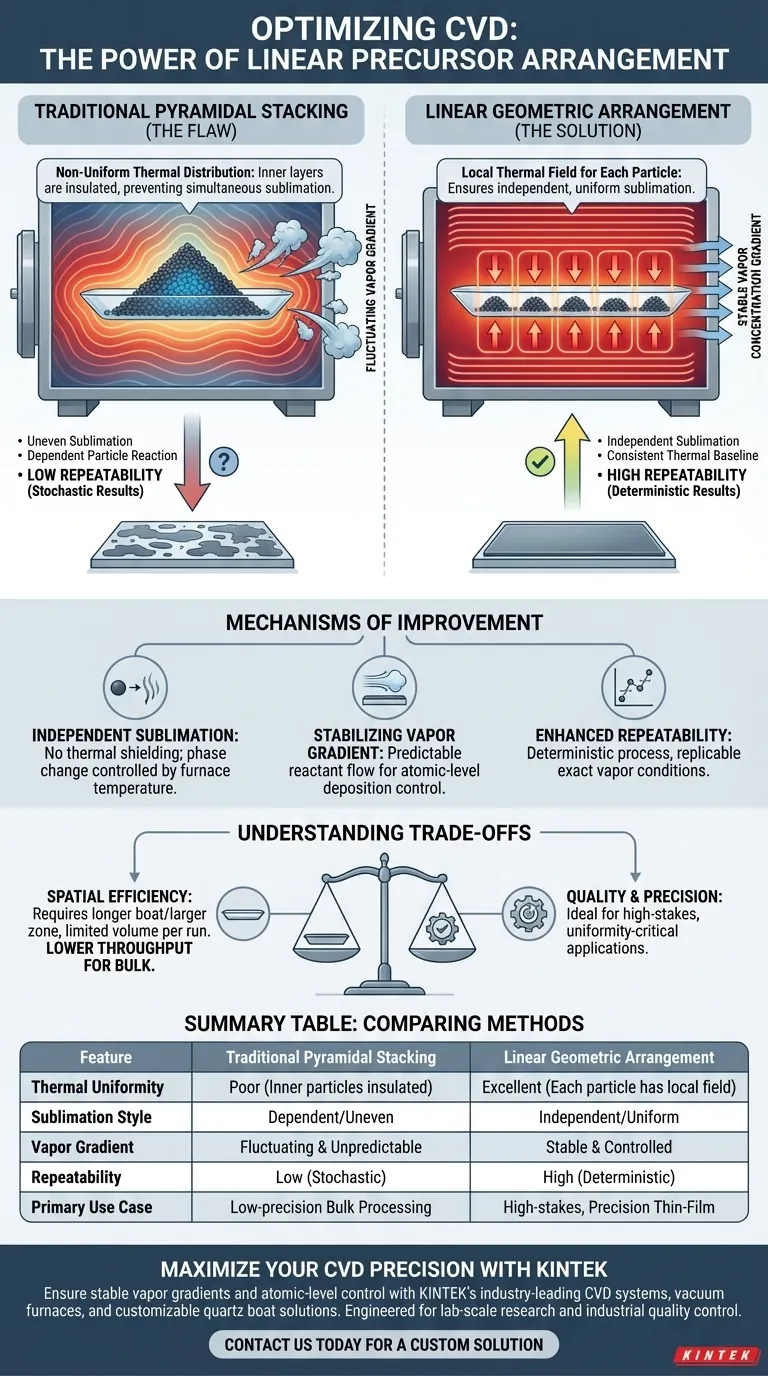

The linear geometric arrangement of precursors within a quartz boat improves the Chemical Vapor Deposition (CVD) process by eliminating the thermal inconsistencies found in traditional methods. By spacing precursor particles linearly rather than piling them in a pyramidal shape, the system ensures each particle is exposed to its own local thermal field. This allows for independent sublimation of materials, creating a stable vapor concentration gradient and significantly enhancing experimental repeatability.

Traditional pyramidal stacking often masks particles from heat, causing uneven sublimation and inconsistent results. A linear arrangement ensures every particle reacts to the temperature independently, stabilizing the vapor flow and making the process highly reproducible.

Overcoming Thermal Inconsistency

The Flaw in Pyramidal Stacking

In traditional CVD setups, precursors are often piled in a pyramidal arrangement. This structure creates significant issues with non-uniform temperature distribution.

The outer layers of the pile insulate the inner layers, preventing them from reaching the necessary sublimation temperature simultaneously. This results in an unpredictable release of vapor.

The Linear Advantage

A linear arrangement creates a geometry where particles are spread out rather than stacked.

This configuration ensures that every individual precursor particle—such as Tin Iodide (SnI2)—is directly exposed to the heat source. By removing the insulation effect of the pile, the system achieves a uniform thermal baseline for all material.

Mechanisms of Improvement

Independent Sublimation

The core physical benefit of this arrangement is the creation of a local thermal field for each particle.

Because the particles are not thermally shielding one another, they undergo independent sublimation. This ensures that the phase change from solid to gas occurs based on the furnace's controlled temperature, not the unpredictable thermal mass of a precursor pile.

Stabilizing the Vapor Concentration Gradient

Consistent sublimation leads directly to a stable precursor vapor concentration gradient within the reaction chamber.

In CVD, the quality of the film deposited on the substrate depends heavily on the consistency of the gas reaching it. The linear design creates a steady, predictable flow of reactants, which is essential for atomic-level deposition control.

Enhanced Repeatability

The primary metric improved by this method is repeatability.

When thermal variables are removed from the precursor source, the experiment becomes deterministic rather than stochastic. Researchers and engineers can replicate the exact vapor conditions in subsequent runs, a critical factor for scientific validation and industrial quality control.

Understanding the Trade-offs

Spatial Efficiency vs. Uniformity

While the linear arrangement offers superior control, it is less spatially efficient than a pile.

Spreading precursors out requires a longer quartz boat or a larger heating zone within the furnace to accommodate the same mass of material. This may limit the total volume of precursor available for a single run compared to a dense stack.

Process Throughput

Because of the spatial requirements, linear arrangements may have lower throughput for bulk coating operations.

This method prioritizes quality and precision over raw volume. It is ideal for high-stakes coating applications where uniformity is non-negotiable, but may be less suitable for rapid, low-precision bulk processing.

Making the Right Choice for Your Goal

To determine if a linear precursor arrangement is required for your specific CVD process, consider your primary objectives:

- If your primary focus is High Precision and Repeatability: Adopt the linear arrangement to ensure stable vapor gradients and eliminate thermal shielding between particles.

- If your primary focus is Complex Precursor Materials (e.g., SnI2): Use the linear design to ensure independent sublimation, preventing incomplete vaporization or inconsistent film stoichiometry.

By aligning the physical geometry of your precursors with the thermal physics of the furnace, you transform a variable process into a controlled, reproducible science.

Summary Table:

| Feature | Traditional Pyramidal Stacking | Linear Geometric Arrangement |

|---|---|---|

| Thermal Uniformity | Poor (Inner particles are insulated) | Excellent (Each particle has local thermal field) |

| Sublimation Style | Dependent/Uneven | Independent/Uniform |

| Vapor Gradient | Fluctuating and unpredictable | Stable and controlled |

| Repeatability | Low (Stochastic results) | High (Deterministic results) |

| Primary Use Case | Low-precision bulk processing | High-stakes, precision thin-film coatings |

Maximize Your CVD Precision with KINTEK

Don't let inconsistent thermal fields compromise your research or production. KINTEK provides industry-leading CVD systems, vacuum furnaces, and customizable quartz boat solutions engineered to ensure stable vapor gradients and atomic-level control. Backed by expert R&D and precision manufacturing, our high-temp furnace solutions are tailored to meet the unique needs of lab-scale research and industrial quality control.

Ready to achieve superior film repeatability? Contact us today for a custom solution and see how our expertise can enhance your deposition process.

Visual Guide

References

- Manab Mandal, K. Sethupathi. In Situ Simultaneous Growth of Layered SnSe<sub>2</sub> and SnSe: a Linear Precursor Approach. DOI: 10.1002/admi.202500239

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a dual-zone tube furnace necessary for MnO2/CF phosphorization? Master CVD Synthesis with Precision Control

- What is the core function of a customized chlorination reactor? Optimize Ta-C Composite CVD Preparation

- What are the applications of CVD in the automotive industry? Boost Vehicle Performance with Advanced Coatings

- What is the purpose of a nested dual-quartz tube configuration in a CVD system? Optimize TB-MoS2 Synthesis Results

- What physical conditions affect graphene production? Master CVD Synthesis for High-Quality Results

- Why is Ar/H2 necessary for copper selenide CVD? Ensure High Purity and Uniform Synthesis

- What are CVD materials? A Guide to High-Performance Thin Films and Coatings

- What is the role of a Chemical Vapor Deposition (CVD) system? Precision Growth for Nanoporous Capillary Grippers