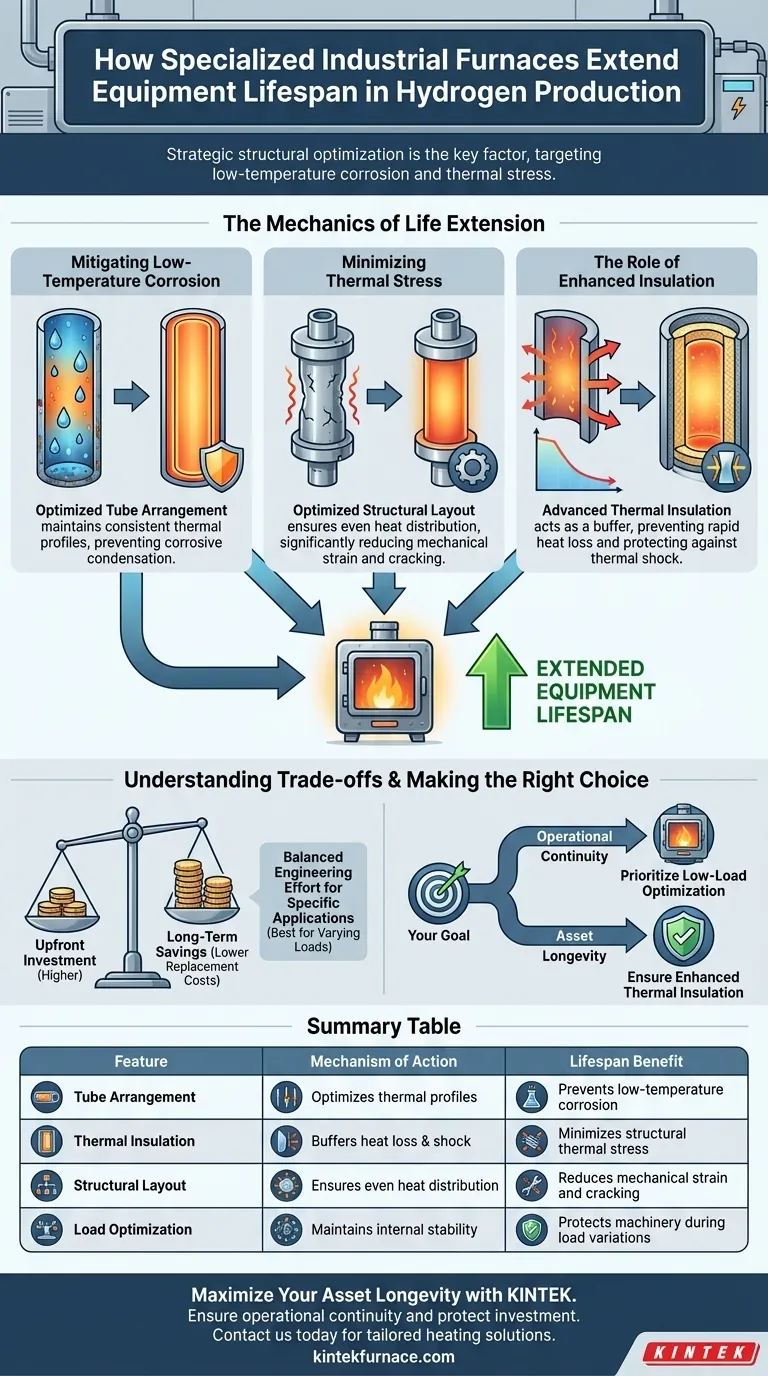

Strategic structural optimization is the key factor. Specialized industrial furnaces extend equipment lifespan by utilizing optimized furnace tube arrangements and enhanced thermal insulation. These design choices specifically target and neutralize the risks of low-temperature corrosion and thermal stress, particularly when the system is running at low operational loads.

Hydrogen production equipment often faces degradation during varying load conditions. By optimizing internal structures and insulation to stabilize temperatures, specialized furnaces prevent the physical and chemical damage that typically shortens operational life.

The Mechanics of Life Extension

Mitigating Low-Temperature Corrosion

Standard furnaces are vulnerable when operating at low loads. In these conditions, temperatures can drop below critical thresholds, leading to corrosive condensation on internal surfaces.

Specialized designs utilize optimized tube arrangements to maintain consistent thermal profiles. This prevents the formation of corrosive elements that degrade metal surfaces over time.

Minimizing Thermal Stress

Fluctuating loads often cause rapid temperature changes, expanding and contracting metal components. This cycle creates thermal stress, which eventually leads to cracks and structural failure.

By optimizing the structural layout, these furnaces ensure even heat distribution. This significantly reduces the mechanical strain on the equipment during operational shifts.

The Role of Enhanced Insulation

Advanced thermal insulation is critical for maintaining internal stability. It acts as a buffer, preventing rapid heat loss when energy input decreases.

This stability protects the equipment from the thermal shock associated with energy loss. It ensures the internal environment remains benign for the machinery, even under varying loads.

Understanding the Trade-offs

Balancing Upfront Investment

While these specialized designs reduce long-term replacement costs, they typically represent a calculated engineering effort. The optimization of tube arrangements and high-grade insulation materials may increase initial capital expenditure compared to standard units.

Specificity of Application

These structural optimizations are specifically tailored for the thermal dynamics of hydrogen production. The benefits are most pronounced in facilities that experience frequent load variations; constant-load facilities may see a slightly lower marginal return on the specialized corrosion-prevention features.

Making the Right Choice for Your Goal

To derive the most value from these furnace designs, align your operational strategy with the equipment's capabilities.

- If your primary focus is operational continuity: Prioritize designs that explicitly mention low-load optimization to prevent unexpected downtime caused by corrosion failures.

- If your primary focus is asset longevity: Ensure the furnace features enhanced thermal insulation to minimize the cumulative damage of thermal stress over years of operation.

By addressing the root causes of degradation through structural design, you secure a more resilient and profitable hydrogen production process.

Summary Table:

| Feature | Mechanism of Action | Lifespan Benefit |

|---|---|---|

| Tube Arrangement | Optimizes thermal profiles | Prevents low-temperature corrosion |

| Thermal Insulation | Buffers heat loss & shock | Minimizes structural thermal stress |

| Structural Layout | Ensures even heat distribution | Reduces mechanical strain and cracking |

| Load Optimization | Maintains internal stability | Protects machinery during load variations |

Maximize Your Asset Longevity with KINTEK

Ensure operational continuity and protect your investment from the risks of thermal stress and corrosion. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces, all customizable for your unique hydrogen production and thermal processing needs.

Don't let equipment degradation stall your progress. Contact us today to discover our tailored heating solutions and secure a more resilient production process.

Visual Guide

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What types of materials can crucible furnaces melt? Unlock the Power of Versatile Melting

- Why is a fluidized bed reactor considered ideal for the co-gasification of biomass and non-biomass waste?

- What role does an oscillating heating stage play in WO3 thin film growth? Control Kinetics and Crystal Orientation

- How are electric furnaces applied in powder metallurgy and 3D printing? Unlock Precision Sintering and Heat Treatment

- What is the function of a laboratory vacuum drying oven for Fe-N-C catalysts? Preserve Nanoporous Structure

- Why is the water quenching process necessary for high-entropy alloys? Master Phase Purity and Microstructural Integrity

- How do high-precision industrial furnaces contribute to thermal stability research in cement composites?

- Importance of NaH2PO2 Layout in V-Ni3S2/NF Phosphorization: Ensuring Uniform 3D Doping