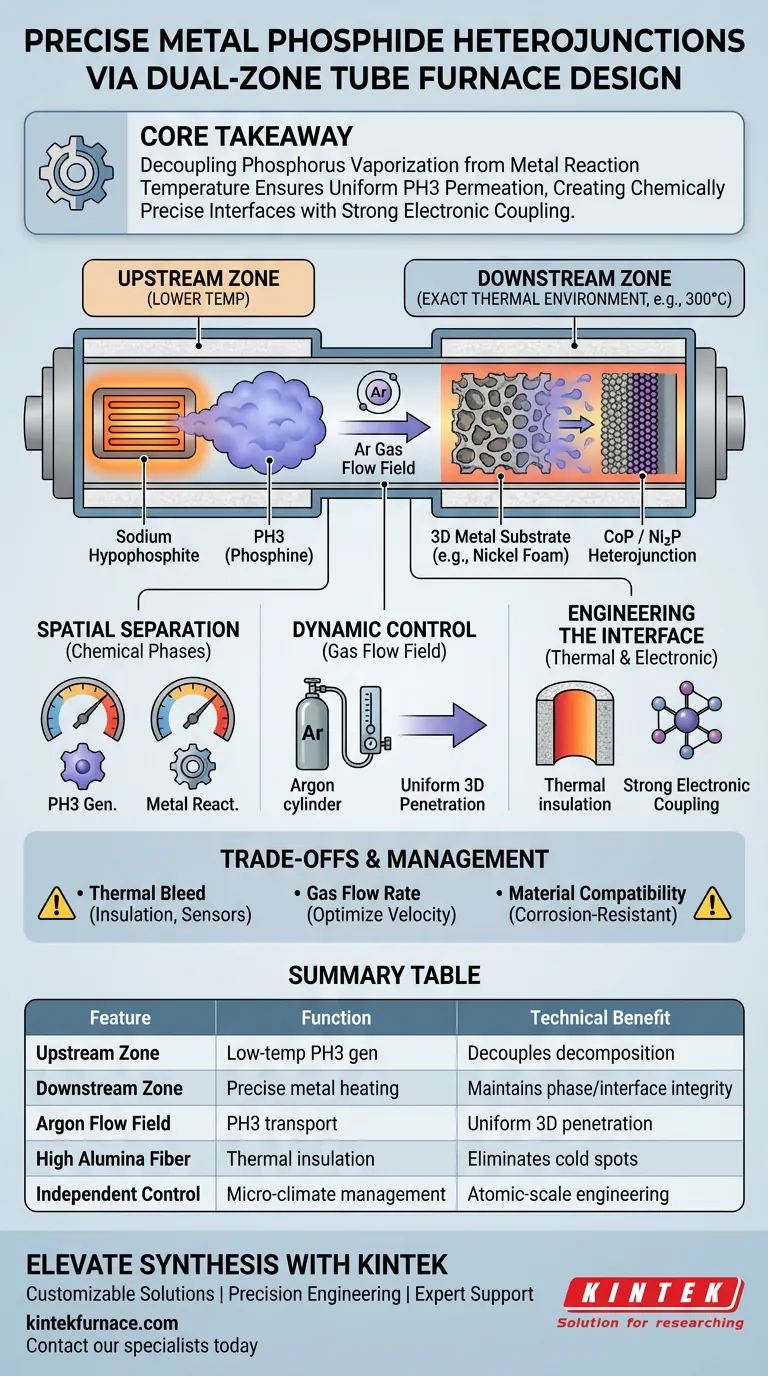

The design of a dual-zone Tube Furnace facilitates precise metal phosphide conversion by decoupling the vaporization of the phosphorus source from the reaction temperature of the metal precursor. This spatial separation allows the upstream zone to decompose sodium hypophosphite into reactive phosphine ($PH_3$) gas at a lower temperature, while the downstream zone maintains the exact thermal environment required for the in-situ formation of the heterojunction.

Core Takeaway: A dual-zone system creates independent thermal micro-climates that ensure $PH_3$ gas uniformly permeates the 3D metal substrate, resulting in a chemically precise heterojunction interface with strong electronic coupling.

The Architectural Logic of Dual-Zone Heating

Spatial Separation of Chemical Phases

In a dual-zone configuration, the upstream zone acts as the gas generator. By heating sodium hypophosphite independently, the system ensures a steady, controlled release of $PH_3$ without prematurely exposing the metal precursors to high heat.

The downstream zone houses the metal hydroxide precursor and the substrate, such as nickel foam. This separation ensures that the metal substrate only encounters the phosphorus source once the ideal reaction temperature is reached.

Dynamic Control of the Gas Flow Field

The furnace utilizes a stable argon gas flow field to transport the generated $PH_3$ gas. This carrier gas ensures that the reactive phosphorus is delivered at a consistent rate to the downstream reaction site.

The design facilitates uniform penetration of the $PH_3$ into the three-dimensional structures of materials like nickel foam. This leads to an "in-situ" conversion where the precursors and the substrate are transformed simultaneously into $CoP$ and $Ni_2P$.

Engineering the Heterojunction Interface

Precise Thermal Insulation and Distribution

The chamber is typically lined with high alumina fibers for superior thermal insulation. This minimizes heat loss and allows the furnace to maintain a precise $300^\circ C$ environment, which is critical for the stability of the metal phosphide phase.

Equipped with all-round heaters, the system ensures a uniform temperature distribution across the tube. This uniformity prevents "cold spots" that could cause incomplete conversion or structural defects at the heterojunction interface.

Facilitating Strong Electronic Coupling

By controlling the temperature zones precisely, the system allows for the construction of a heterojunction interface at the microscopic scale. This precision leads to strong electronic coupling effects between the different metal phosphide phases.

These coupling effects are essential for the material's performance, as they optimize the electronic structure for applications like electrocatalysis. The dual-zone design is the primary tool for achieving this level of atomic-scale engineering.

Understanding the Trade-offs and Challenges

The Complexity of Thermal Gradients

Managing two distinct temperature zones in a single tube can lead to thermal bleed, where heat from the hotter zone migrates to the cooler zone. This requires sophisticated insulation and precise sensor placement to prevent the phosphorus source from decomposing too rapidly.

Gas Flow Management

If the argon flow rate is too high, the $PH_3$ gas may bypass the metal precursor too quickly for full conversion. Conversely, a flow rate that is too low can lead to an accumulation of byproduct gases, which may contaminate the heterojunction interface.

Material Compatibility

The corrosive nature of $PH_3$ gas requires the tube and internal components to be highly resistant to chemical attack. Maintaining the integrity of the fixed well tube reactor over multiple high-temperature cycles is a persistent maintenance challenge.

How to Apply This to Your Research or Production

To maximize the efficiency of your dual-zone phosphidation process, consider the following strategic approaches:

- If your primary focus is phase purity: Prioritize the calibration of the upstream zone to ensure the sodium hypophosphite decomposes at a rate that matches the absorption capacity of your metal precursor.

- If your primary focus is 3D structural integrity: Optimize the argon flow velocity to ensure $PH_3$ reaches the internal pores of high-surface-area substrates like nickel foam without causing physical deformation.

- If your primary focus is electronic coupling strength: Focus on the precise $300^\circ C$ downstream temperature control to ensure the $CoP$ and $Ni_2P$ phases form a sharp, well-defined interface.

By mastering the independent control of these two thermal environments, you can achieve unprecedented precision in the synthesis of advanced heterojunction materials.

Summary Table:

| Feature | Function in Phosphidation | Technical Benefit |

|---|---|---|

| Upstream Zone | Low-temp $PH_3$ generation | Decouples decomposition from metal reaction |

| Downstream Zone | Precise metal precursor heating | Maintains phase stability and interface integrity |

| Argon Flow Field | $PH_3$ transport medium | Ensures uniform 3D penetration of substrates |

| High Alumina Fiber | Thermal insulation | Eliminates cold spots and prevents thermal bleed |

| Independent Control | Micro-climate management | Enables atomic-scale engineering of interfaces |

Elevate Your Material Synthesis with KINTEK

Unlock the full potential of your heterojunction research with KINTEK’s advanced dual-zone systems. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to provide the independent thermal control and gas flow management essential for high-performance metal phosphides.

Why choose KINTEK?

- Customizable Solutions: Tailored configurations for unique research needs.

- Precision Engineering: Achieve sharp interfaces and strong electronic coupling.

- Expert Support: Specialized equipment for lab and industrial high-temp applications.

Contact our specialists today to discover how our customizable furnace systems can enhance your lab's precision and efficiency.

Visual Guide

References

- Zhong Li, Xiaochen Dong. Reversing the Interfacial Electric Field in Metal Phosphide Heterojunction by Fe‐Doping for Large‐Current Oxygen Evolution Reaction. DOI: 10.1002/advs.202308477

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a high-temperature tube furnace in the preparation of Black-TiO2? Enhance Photocatalytic Power

- What is the primary function of a high-temperature tube furnace in Se@void@BLNC preparation? Master Dual Synthesis

- What safety precautions should be taken when using a High Temperature Tube Furnace? Essential Tips for Safe Operation

- What role does a high-precision vertical tube furnace play in nickel ore smelting? Master Industrial Smelting Simulation

- Why is a multi-zone tube furnace required for TCVD? Optimize Thermal Management for Precursors

- What is the function of vacuum-sealed tubes and controlled heating? Master Ruthenium Precursor Embedding

- What is the technical value of using an industrial-grade tube furnace for titania nanotubes? Enhance Crystal Performance

- What role does an industrial-grade tube furnace play in Fe-P-NC catalyst pyrolysis? Precision Heating for Fe-P-NC Synthesis