In essence, the dental ceramic block sintering furnace is the critical final step in the digital dentistry workflow. It transforms a soft, milled ceramic blank into a final restoration with the exceptional strength, precise fit, and aesthetic quality required for modern patient care. Without this controlled heating process, the advanced ceramic materials used today would be clinically useless.

The sintering furnace is not merely an oven; it is a precision instrument that unlocks the physical and aesthetic properties of advanced ceramics like zirconia. It bridges the gap between the digital design (CAD/CAM) and a durable, biocompatible final product, making it a cornerstone of high-performance restorative dentistry.

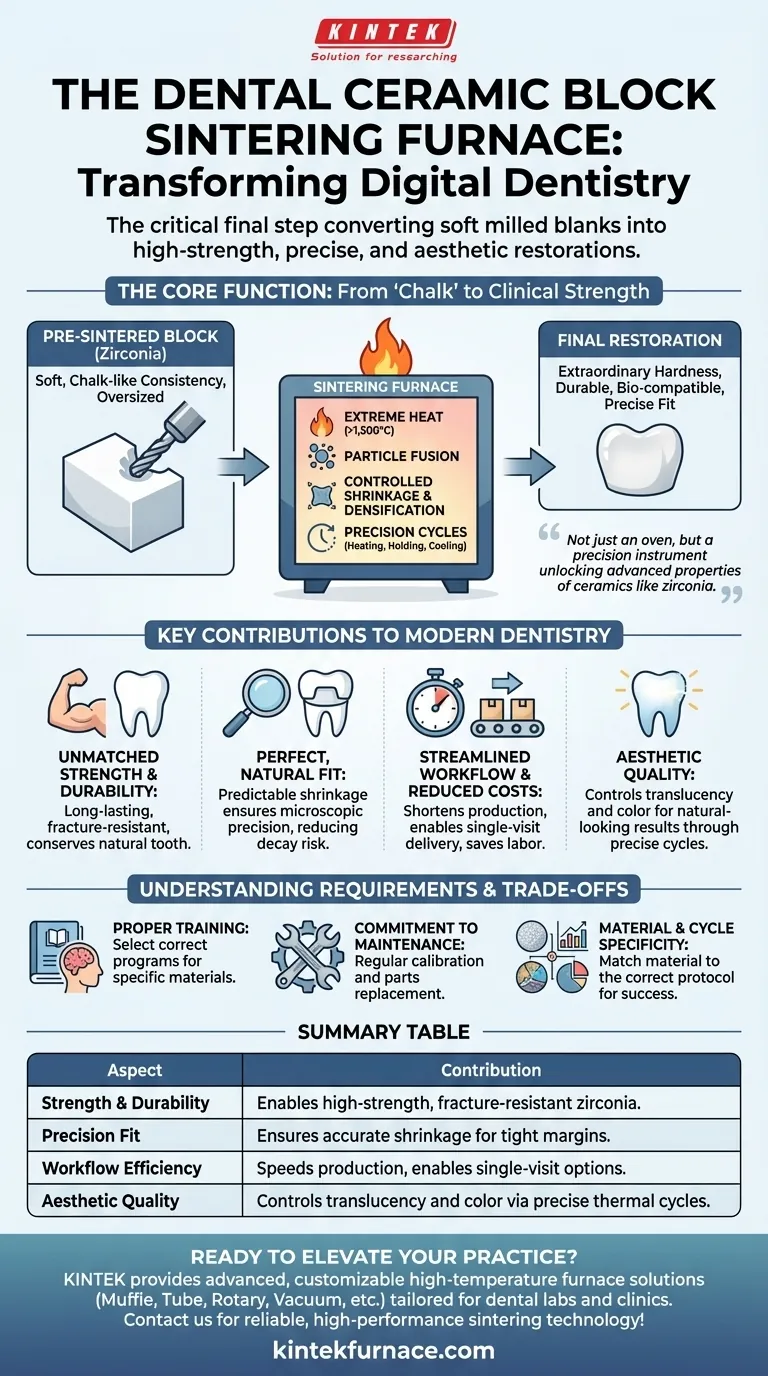

The Core Function: From 'Chalk' to Clinical Strength

The primary role of the sintering furnace is to execute a highly controlled thermal process that fundamentally changes the nature of the ceramic material.

From Pre-Sintered State to Final Form

Dentists or lab technicians start with a pre-sintered block of ceramic, often zirconia. In this state, the material is dense but soft, having the consistency of chalk.

This softness is intentional, as it allows a milling machine to carve the restoration—such as a crown or bridge—quickly and with minimal wear on the milling tools. The furnace's job is to take this fragile, oversized shape and transform it.

The Science of Sintering

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction.

Inside the furnace, the temperature is raised to extreme levels, often over 1,500°C (2,732°F). At this heat, the individual ceramic particles fuse together, eliminating the pores between them and causing the entire restoration to shrink and densify.

This process is what gives the final restoration its extraordinary hardness and ability to withstand significant chewing forces.

The Critical Role of Precision Cycles

A modern sintering furnace does not just get hot; it follows a precise program of heating, holding, and cooling.

These carefully managed cycles are crucial for preventing thermal shock that could crack the restoration. They also ensure the material shrinks uniformly, which is essential for achieving the highly accurate fit designed in the software. Different cycles can also influence the final translucency and color of the ceramic, impacting the aesthetic outcome.

Key Contributions to Modern Dentistry

The integration of sintering furnaces provides clear benefits across clinical quality, workflow efficiency, and economic viability.

Unmatched Strength and Durability

Sintered zirconia is one of the strongest and most durable materials available in dentistry. This allows for long-lasting restorations that are highly resistant to fracture, even in thin sections, which helps conserve more of the patient's natural tooth structure.

Achieving a Perfect, Natural Fit

The furnace is the final link in the digital chain that starts with an intraoral scanner. Because the shrinkage is predictable and controlled, the final sintered crown fits the patient's tooth with microscopic precision. This tight margin reduces the risk of secondary decay and gum irritation.

Streamlining the Workflow and Reducing Costs

Compared to traditional casting or layering techniques, a digital workflow with a sintering furnace significantly shortens the production cycle.

This speed allows for faster turnaround times from dental labs. For clinics with in-house systems, it can even enable the delivery of a permanent, high-strength ceramic crown in a single visit, reducing labor costs and improving the patient experience.

Understanding the Requirements and Trade-offs

While powerful, a sintering furnace is not a simple "plug-and-play" appliance. Achieving consistent, high-quality results depends on understanding its operational requirements.

The Necessity of Proper Training

Operators must be trained to select the correct sintering program for the specific ceramic material being used. Different types of zirconia (e.g., high-strength for posteriors vs. high-translucency for anteriors) require different temperature curves and hold times.

The Commitment to Maintenance

These furnaces require regular calibration to ensure temperature accuracy. Heating elements and other components have a finite lifespan and must be replaced as part of a routine maintenance schedule. Neglecting this leads to inconsistent results, failed restorations, and wasted materials.

Material and Cycle Specificity

There is no universal sintering cycle. Using the wrong program can result in a restoration with poor aesthetics, incorrect fit, or compromised strength. Success depends on a disciplined, knowledge-based approach that matches the material to the correct furnace protocol every time.

Making the Right Choice for Your Goal

Integrating this technology requires a clear understanding of your primary objectives.

- If your primary focus is clinical excellence: The furnace is non-negotiable for delivering ceramic restorations with the highest standards of strength, fit, and biocompatibility.

- If your primary focus is practice efficiency: This technology is the engine for reducing turnaround times, enabling single-visit dentistry, and achieving greater control over your production schedule.

- If your primary focus is long-term reliability: Your success hinges on a commitment to rigorous operator training and a strict maintenance schedule to guarantee predictable outcomes.

Ultimately, the dental sintering furnace empowers professionals to translate digital precision into a physical reality with confidence.

Summary Table:

| Aspect | Contribution |

|---|---|

| Strength & Durability | Enables high-strength zirconia restorations resistant to fracture, preserving natural tooth structure. |

| Precision Fit | Ensures accurate shrinkage for tight margins, reducing decay risk and improving patient outcomes. |

| Workflow Efficiency | Speeds production, allowing single-visit crowns and faster lab turnarounds for cost savings. |

| Aesthetic Quality | Controls translucency and color through precise thermal cycles for natural-looking results. |

Ready to elevate your dental practice with precision sintering solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental labs and clinics. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental and production needs. Whether you're aiming for clinical excellence, improved efficiency, or long-term reliability, our furnaces deliver unmatched strength, fit, and workflow benefits. Contact us today to discuss how we can support your goals with reliable, high-performance sintering technology!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns