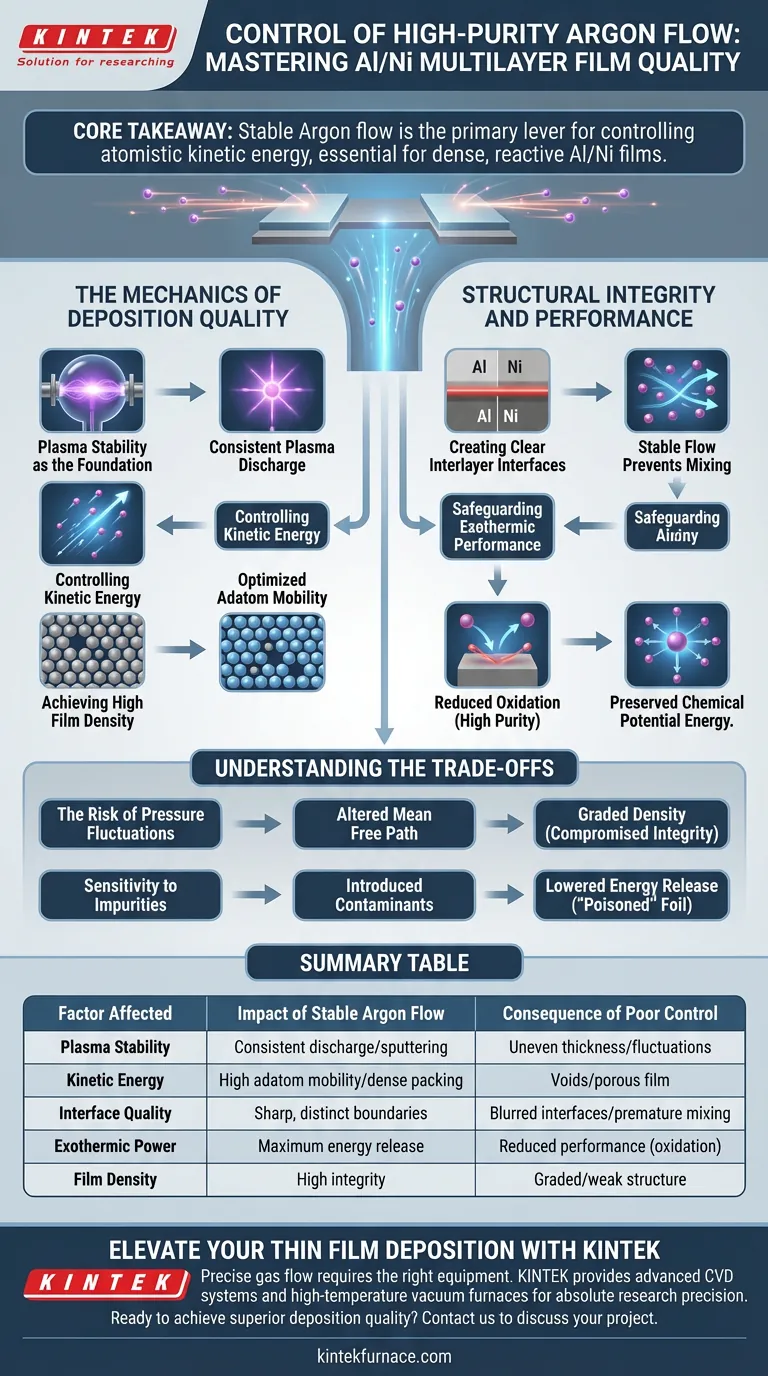

Precise control of high-purity Argon flow is the governing factor in stabilizing the sputtering plasma used for Al/Ni deposition. By regulating this flow, you effectively dictate the kinetic energy of the sputtered Aluminum and Nickel atoms as they travel to the substrate. This control is essential for creating high-density films with the sharp, clear interfaces necessary for the material's reactive performance.

Core Takeaway: Stability in Argon gas flow is not just about maintaining chamber pressure; it is the primary lever for controlling atomistic kinetic energy. This control minimizes oxidation and creates the distinct, dense layering required to preserve the maximum exothermic energy release of Al/Ni films.

The Mechanics of Deposition Quality

Plasma Stability as the Foundation

Argon acts as the discharge medium for the physical vapor deposition process.

Maintaining a stable flow ensures that the plasma discharge remains consistent throughout the coating run.

Without this consistency, the sputtering rate fluctuates, leading to uneven film thickness and unpredictable material properties.

Controlling Kinetic Energy

The flow of Argon directly influences the vacuum pressure and, consequently, the energy of the sputtered atoms.

By optimizing this flow, you control the kinetic energy with which Aluminum and Nickel atoms impact the substrate.

Higher kinetic energy (within optimal limits) facilitates better adatom mobility, allowing atoms to settle into a more compact structure.

Achieving High Film Density

The immediate result of controlled kinetic energy is high film density.

Dense films are less porous and mechanically more robust.

This density is achieved because the energetic impact packs the atoms tightly, eliminating voids that could weaken the structure.

Structural Integrity and Performance

Creating Clear Interlayer Interfaces

Al/Ni multilayer films function as reactive foils, releasing energy when the layers mix.

To maximize this reaction, the boundaries between the Aluminum and Nickel layers must be sharp and distinct.

Stable Argon flow prevents energetic variances that could cause premature intermixing or blurred interfaces during the deposition process.

Safeguarding Exothermic Performance

The ultimate goal of Al/Ni films is their exothermic (energy-releasing) capability.

High-purity Argon flow creates an environment that drastically reduces unintended oxidation.

By preventing oxygen and other impurities from contaminating the layers, you preserve the chemical potential energy stored within the film.

Understanding the Trade-offs

The Risk of Pressure Fluctuations

If Argon flow is not precisely controlled, chamber pressure will drift.

A drift in pressure alters the mean free path of the sputtered atoms.

This leads to a variance in impact energy, potentially resulting in a film with graded density rather than uniform density, compromising structural integrity.

Sensitivity to Impurities

Even with high-purity gas, flow interruptions can introduce contaminants.

Any introduction of impurities acts as a barrier to the Al/Ni reaction.

This effectively "poisons" the reactive foil, significantly lowering the total energy it can release upon activation.

Optimizing Your Deposition Process

To ensure the highest quality Al/Ni multilayer films, align your gas control strategy with your specific performance metrics:

- If your primary focus is Structural Density: Prioritize flow stabilization to maintain consistent kinetic energy, ensuring atoms pack tightly without voids.

- If your primary focus is Exothermic Power: Prioritize the use of high-purity Argon and strict leak control to eliminate oxidation and preserve sharp interlayer interfaces.

Mastery of Argon flow turns a standard coating process into a precision engineering tool, ensuring your reactive films deliver their maximum energy potential.

Summary Table:

| Factor Affected | Impact of Stable Argon Flow | Consequence of Poor Control |

|---|---|---|

| Plasma Stability | Consistent discharge and sputtering rates | Uneven film thickness and fluctuations |

| Kinetic Energy | High adatom mobility for dense packing | Voids and porous film structure |

| Interface Quality | Sharp, distinct layer boundaries | Blurred interfaces and premature mixing |

| Exothermic Power | Maximum energy release capability | Reduced performance due to oxidation |

| Film Density | High mechanical and structural integrity | Graded density and structural weakness |

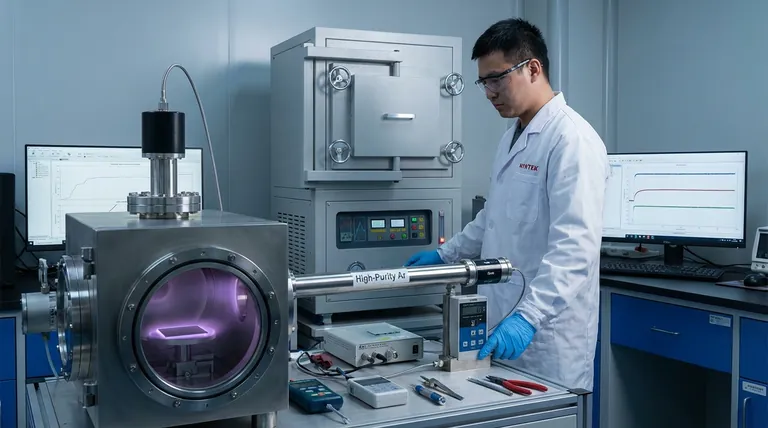

Elevate Your Thin Film Deposition with KINTEK

Precise gas flow is critical for high-performance Al/Ni multilayer films, and having the right equipment is the foundation of that success. KINTEK provides industry-leading lab solutions, including advanced CVD systems and high-temperature vacuum furnaces, engineered for research that demands absolute precision.

Whether you are optimizing reactive foils or developing next-generation coatings, our expert R&D and manufacturing teams are here to deliver customizable systems tailored to your unique specifications.

Ready to achieve superior deposition quality? Contact us today to discuss your project and see how KINTEK’s expertise can empower your laboratory.

Visual Guide

References

- Konrad Jaekel, Heike Bartsch. Influence of Increasing Density of Microstructures on the Self‐Propagating Reaction of Al/Ni Reactive Nanoscale Multilayers. DOI: 10.1002/adem.202302225

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the necessity of a laboratory vacuum drying oven for photocatalytic powders? Protect Your Material Integrity

- What is the technical objective of performing thermal oxidation at 625 °C? Mastering SiOx Tunnel Oxide Precision

- What are the primary functions of a high-precision dilatometer in hot ductility? Optimize Steel Casting Precision

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- What is the purpose of using a vacuum dryer for PU and AlN composite sheets? Enhance Thermal & Structural Integrity

- Why do substrates undergo treatment in a high-temperature annealing furnace? Perfecting PtTe2/WTe2 Heterostructures

- What is the specific function of laboratory electric heating devices in solid-state hydrogen storage? Optimize Thermal Management

- Why is a high-precision high-temperature furnace required for mechanical testing? Secure Reliable Material Data