Atmosphere control is the defining variable that determines the success of cuprous oxide (Cu2O) synthesis. Specifically, the tube furnace acts as an isolation chamber, utilizing a stable nitrogen environment to strictly enforce an inert atmosphere. This setup arrests the oxidation process, preventing the Cu2O from oxidizing further into cupric oxide (CuO).

Core Takeaway The tube furnace functions not merely as a heat source, but as a thermodynamic lock. By excluding oxygen through a controlled inert nitrogen flow, it stabilizes copper in the +1 oxidation state (Cu2O), ensuring the specific electronic structure and phase purity required for high-performance electrochemical catalysis.

The Mechanism of Phase Stabilization

Arresting Oxidation at the Critical Point

Copper is highly reactive with oxygen at elevated temperatures. Without intervention, copper species naturally tend toward their most stable oxidation state, which is often cupric oxide (CuO).

The primary function of the tube furnace in this context is to introduce a nitrogen inert environment.

This inert blanket effectively halts the chemical reaction trajectory, stopping the oxidation at the Cu2O stage and preventing the unwanted transition to CuO.

Preserving Electronic Structure

The catalytic capability of a material is dictated by its electronic structure. Cu2O possesses distinct electronic properties that differ significantly from CuO.

By maintaining the inert state, the furnace ensures the material retains the specific electron configuration associated with the copper(I) oxide phase.

This preservation is non-negotiable for the catalyst's final performance in electrochemical reactions.

The Role of the Tube Furnace Environment

Creating a Physicochemical Barrier

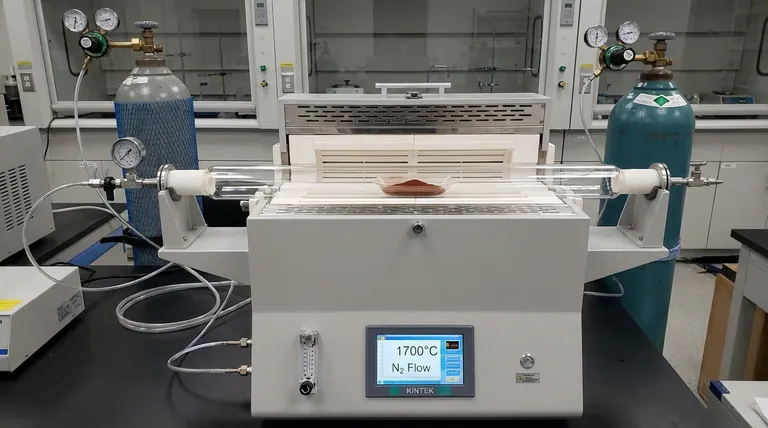

A tube furnace provides a confined, controllable volume where the atmosphere can be precisely regulated.

Unlike open-air calcination, which allows thermodynamic interaction with residual air, the tube furnace creates a critical physicochemical environment.

This environment isolates the sample from external variables, ensuring that the only thermal energy acts on the sample, without the chemical interference of atmospheric oxygen.

Ensuring Phase Purity

Phase purity refers to the homogeneity of the crystal structure within the sample.

In catalyst synthesis, even a small percentage of impurity (such as mixed CuO phases) can severely degrade performance.

The stable nitrogen flow within the tube furnace guarantees that the entire sample remains in the Cu2O phase, preventing the formation of heterogeneous mixtures that result from partial oxidation.

Understanding the Trade-offs

The Fragility of the Inert State

While the tube furnace excels at isolation, the system is only as robust as its seal and flow consistency.

Cu2O is thermodynamically sensitive; even minor leaks or interruptions in the nitrogen flow can reintroduce oxygen.

This "secondary oxidation" is a common failure mode, instantly degrading the catalyst back into a CuO or mixed-phase state.

Inert vs. Reducing Atmospheres

It is crucial to distinguish between an inert atmosphere and a reducing atmosphere.

Other catalyst syntheses may require reducing gases (like H2/Ar mixtures) to strip ligands or form alloys.

However, for Cu2O, the goal is stasis, not reduction. Using a reducing atmosphere could potentially reduce the oxide back to metallic copper, missing the target oxide phase entirely.

Making the Right Choice for Your Goal

If your primary focus is High Electrochemical Activity:

- Prioritize a robust nitrogen purge system to guarantee 100% exclusion of oxygen, as phase purity directly correlates to electronic performance.

If your primary focus is Process Repeatability:

- Implement strict monitoring of gas flow rates and furnace seal integrity to prevent batch-to-batch variations caused by "micro-leaks" of ambient air.

If your primary focus is Structural Stability:

- Ensure the cooling phase also occurs under the nitrogen flow, as re-oxidation can occur if the sample is exposed to air while still hot.

Mastering the atmosphere is not just about preventing oxidation; it is about precision engineering the atomic state of your catalyst.

Summary Table:

| Feature | Role in Cu2O Synthesis | Impact on Catalyst |

|---|---|---|

| Inert Nitrogen Flow | Displaces oxygen and prevents further oxidation | Ensures Cu(I) phase purity and prevents CuO formation |

| Sealed Isolation | Creates a physicochemical barrier from ambient air | Maintains a stable thermodynamic environment for the sample |

| Phase Stabilization | Arrests chemical reaction at the critical +1 state | Preserves the specific electronic structure for catalysis |

| Cooling Control | Maintains inert gas flow during the temperature drop | Prevents post-synthesis re-oxidation of hot samples |

Precision is paramount in catalyst synthesis. At KINTEK, we understand that a tube furnace is more than just a heater—it is a thermodynamic lock for your research. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the rigorous atmosphere control required for high-performance Cu2O and other specialized lab applications. Contact us today to find the perfect high-temp furnace for your unique needs.

References

- Wanru Liao, Min Liu. Sustainable conversion of alkaline nitrate to ammonia at activities greater than 2 A cm−2. DOI: 10.1038/s41467-024-45534-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What kind of experimental environment does a high vacuum tube furnace provide for high-performance ceramic preparation?

- How do tube furnaces contribute to energy efficiency? Boost Your Lab's Performance with Advanced Thermal Solutions

- What makes fluidized bed vertical tube furnaces environmentally friendly? Discover Efficient Green Tech Solutions

- How does the industrial tube furnace contribute to Fe-N-C catalyst synthesis? Master High-Temperature Carbonization

- What technical advantages do three-zone tube furnaces offer? Superior Temperature Control and Flexibility

- What is the primary function of a high-temperature tube furnace in NaF–Na3AlF6 molten salt experiments? Learn more!

- How does a laboratory tube furnace facilitate the control of pore structures? Master Precision Porous Carbon Synthesis

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab