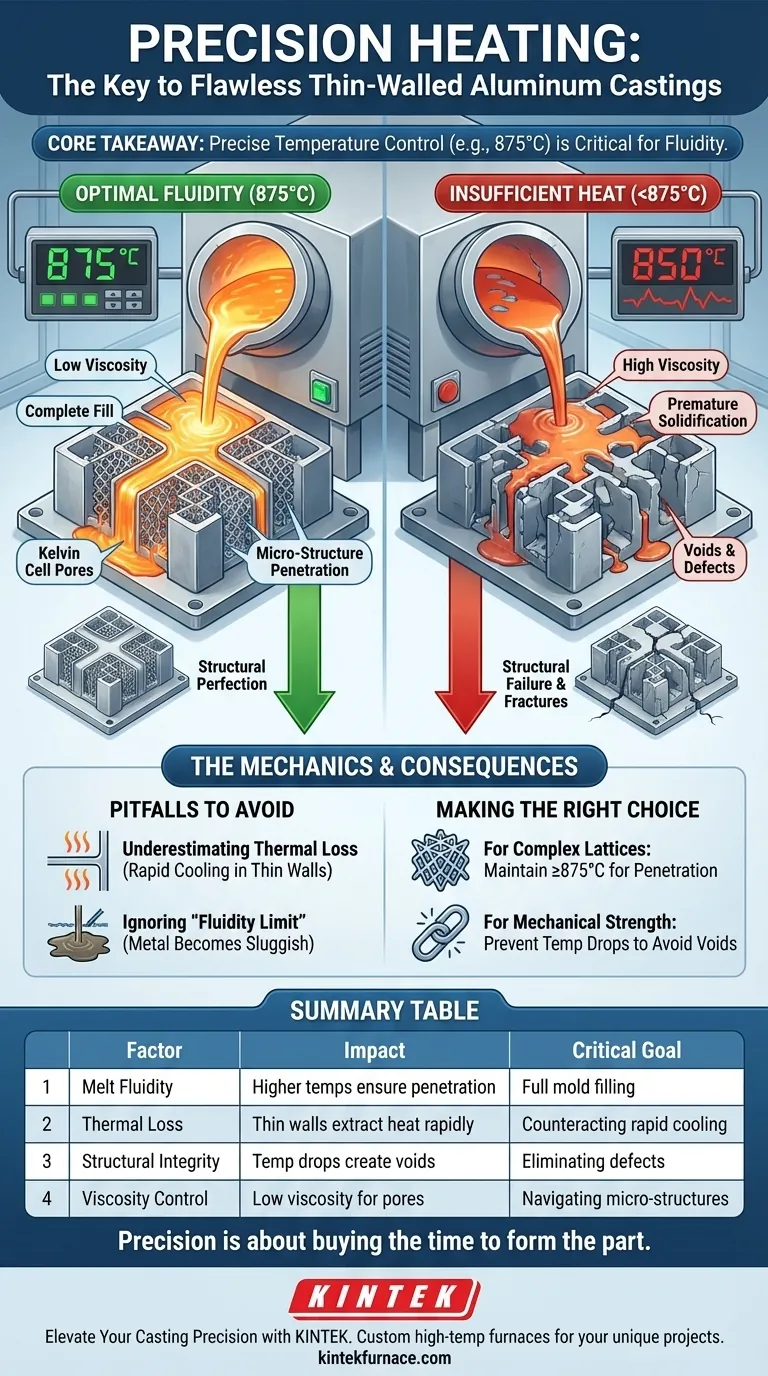

Precise temperature control is the defining factor in achieving successful thin-walled aluminum castings. Specifically, maintaining the melt at a targeted set point, such as 875°C, is critical to ensuring the liquid metal possesses the necessary fluidity to navigate complex geometries. Without this exact thermal regulation, the casting process creates a high risk of structural failure due to incomplete mold filling.

Core Takeaway The structural integrity of thin-walled aluminum parts relies entirely on melt fluidity. Precise heating prevents premature solidification, ensuring the metal can fully penetrate fine lattice structures like Kelvin cell pores without leaving voids or causing fractures.

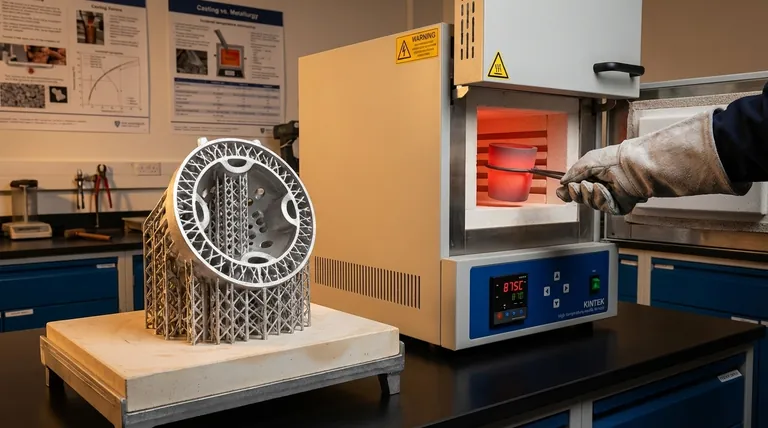

The Mechanics of Melt Fluidity

Ensuring Complete Fill in Complex Geometries

To cast thin-walled structures, the liquid aluminum must travel through narrow channels without freezing. The primary function of high-precision temperature control is to maintain the metal's fluidity. If the temperature is maintained correctly (e.g., 875°C), the viscosity remains low enough for the metal to flow freely into intricate areas.

Penetrating Micro-Structures

Modern castings often contain complex internal features, such as Kelvin cell pores or fine lattices. These features require the liquid to permeate extremely small spaces. Only a melt held at the optimal temperature can successfully navigate these fine lattice networks before cooling occurs.

Consequences of Insufficient Heat

The Danger of Premature Solidification

If the furnace temperature drops below the critical set point, the metal loses thermal energy too rapidly during the pour. This causes the leading edge of the liquid metal to solidify before it reaches the end of the mold or the deepest recesses of the lattice. Essentially, the metal "freezes" in place before the part is fully formed.

Structural Defects and Voids

When the metal solidifies prematurely, it leaves behind empty spaces known as voids. These gaps in the material interrupt the structural continuity of the casting. The result is a finished part plagued by structural fractures and significantly reduced mechanical strength.

Common Pitfalls to Avoid

Underestimating Thermal Loss in Thin Walls

Thin-walled molds extract heat from liquid metal much faster than thick molds. A common mistake is failing to account for this rapid cooling rate when setting furnace parameters. If the initial temperature is not precise enough to counteract this loss, the casting will fail regardless of the mold design.

Ignoring the "Fluidity Limit"

Every alloy has a temperature threshold below which it becomes too sluggish to fill a complex mold. Operating too close to this limit creates a narrow margin for error. You must maintain the temperature high enough—specifically referenced at 875°C for these applications—to guarantee the metal behaves as a fluid rather than a sludge.

Making the Right Choice for Your Goal

To maximize the quality of your aluminum alloy castings, focus on the specific needs of your geometry:

- If your primary focus is complex lattice structures: Prioritize maintaining a set point of at least 875°C to guarantee the fluidity required to fill Kelvin cell pores.

- If your primary focus is mechanical strength: Ensure the melt never drops below the fluidity threshold to prevent voids that act as fracture initiation points.

Precision in heating is not just about melting the metal; it is about buying the time required to form the part.

Summary Table:

| Factor | Impact on Thin-Walled Castings | Critical Goal |

|---|---|---|

| Melt Fluidity | Higher temperatures (e.g., 875°C) ensure penetration of complex lattice structures. | Full mold filling |

| Thermal Loss | Thin walls extract heat rapidly, causing premature solidification. | Counteracting rapid cooling |

| Structural Integrity | Temperature drops create voids and fracture points. | Eliminating mechanical defects |

| Viscosity Control | Low viscosity allows metal to flow into Kelvin cell pores. | Navigating micro-structures |

Elevate Your Casting Precision with KINTEK

Don't let temperature fluctuations compromise the integrity of your complex aluminum castings. KINTEK provides industry-leading thermal solutions backed by expert R&D and world-class manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet the exacting fluidity demands of your unique projects.

Ensure structural perfection in every part. Contact us today to discover how our precision heating technology can optimize your thin-walled manufacturing process.

Visual Guide

References

- Alessandra Ceci, Maria Elisa Tata. Production of Al Alloys with Kelvin Cells Using the Lost-PLA Technique and Their Mechanical Characterization via Compression Tests. DOI: 10.3390/ma18020296

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is the semi-levitation effect generated in induction cold crucible melting? Unlock Ultra-Pure Alloy Synthesis

- What is the necessity of a water cooling unit for high-power induction heating systems? Protect Your Equipment Now

- Why is precise temperature control in an electric melting furnace essential for AZ91D/Si3N4/WGP composites?

- How does an induction furnace affect copper grain size? Optimize Microstructure with Rapid Heating

- What industries commonly use induction melting furnaces? Achieve High-Purity Metal Melting

- What auxiliary role does a Ni/Al2O3 catalyst play in induction heating? Enhancing Ammonia Decomposition Uniformity

- What are the efficiency benefits of IGBT modules in melting machines? Achieve Faster Melting & Superior Quality

- How does the vacuum arc melting process work? Achieve High-Purity Metals for Demanding Applications