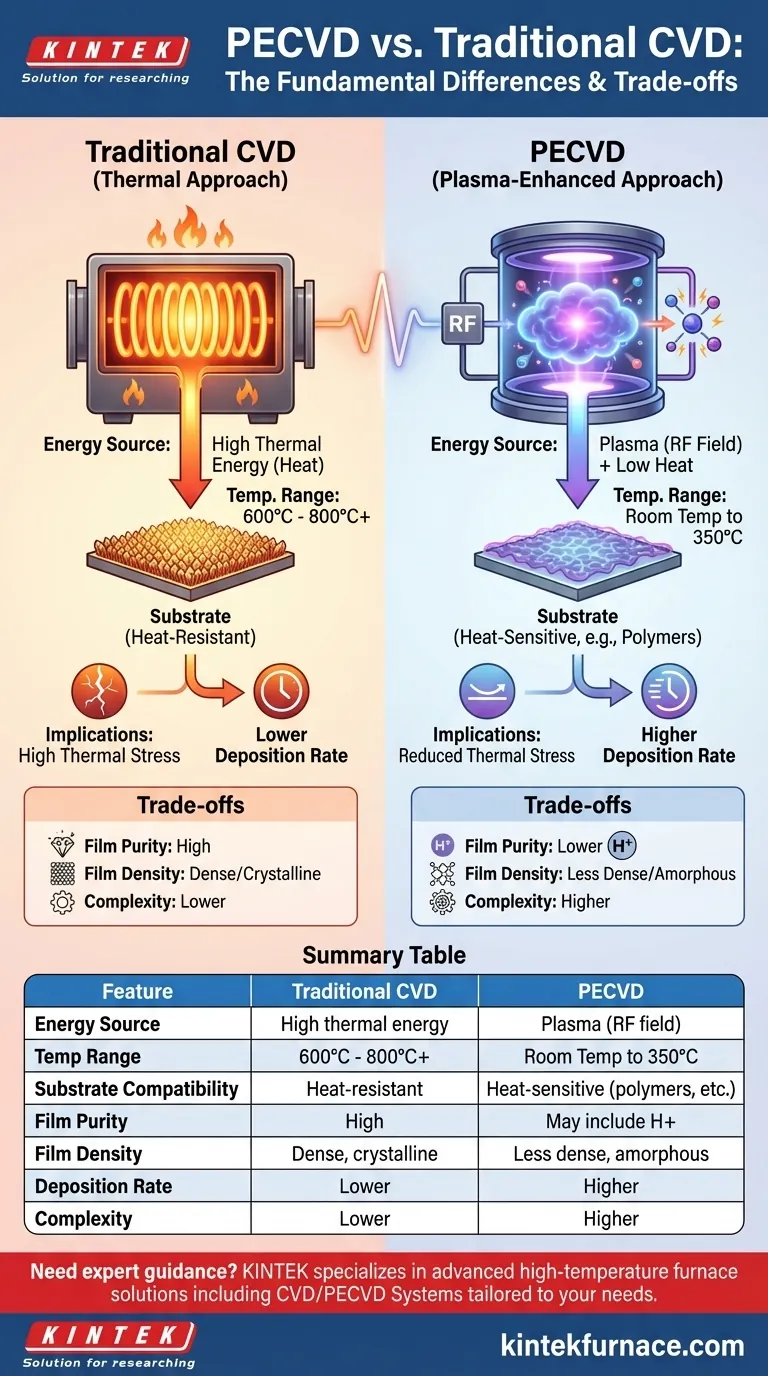

The fundamental difference between Plasma-Enhanced Chemical Vapor Deposition (PECVD) and conventional Chemical Vapor Deposition (CVD) is the energy source used to drive the reaction. While traditional CVD relies exclusively on high thermal energy (heat) to break down precursor gases, PECVD uses an energized plasma to initiate the chemical reactions. This allows PECVD to deposit high-quality thin films at significantly lower temperatures.

At its core, the choice between CVD and PECVD is a trade-off between temperature and process complexity. PECVD's use of plasma enables deposition on heat-sensitive materials, a task impossible for high-temperature conventional CVD.

The Core Distinction: Energy Source and Temperature

The method used to supply energy dictates the operating conditions and, consequently, the applications for each deposition technique.

Traditional CVD: The Thermal Approach

Conventional CVD is a purely thermochemical process. Precursor gases are introduced into a reaction chamber where the substrate is heated to very high temperatures, typically between 600°C and 800°C, and sometimes much higher.

This intense heat provides the activation energy required to break the chemical bonds in the precursor gases, allowing them to react and deposit as a solid thin film onto the substrate surface.

PECVD: The Plasma-Enhanced Approach

PECVD introduces a third element into the chamber: plasma. Plasma, often called the fourth state of matter, is a gas that has been energized, typically by a radio frequency (RF) field, until its atoms are ionized.

This process creates a mix of high-energy electrons, ions, and reactive free radicals. These highly reactive species collide with the precursor gas molecules, breaking them apart and driving the deposition reaction.

The Role of Plasma

Because the plasma—not just heat—provides the energy for the reaction, the substrate can be kept at a much lower temperature. PECVD processes typically run from room temperature up to around 350°C.

This makes plasma the enabling factor for low-temperature deposition, fundamentally expanding the range of materials that can be coated.

Practical Implications of the Temperature Difference

The dramatic reduction in process temperature is not just a minor detail; it is the primary reason for PECVD's widespread adoption and has significant consequences for manufacturing.

Substrate Compatibility

This is the most significant advantage of PECVD. The high heat of traditional CVD would destroy or damage temperature-sensitive substrates like polymers, plastics, and fully fabricated semiconductor devices.

PECVD's low-temperature operation makes it the default choice for depositing films on these types of materials.

Reduced Thermal Stress

High temperatures cause materials to expand, and they contract upon cooling. This can create significant mechanical stress between the substrate and the newly deposited film, leading to cracking, peeling, or warping.

By minimizing the temperature difference, PECVD significantly reduces the thermal stress in the final product, improving its reliability and integrity.

Deposition Rate

At lower temperatures, PECVD can often achieve higher deposition rates than a purely thermal CVD process would at the same temperature. The plasma actively creates a high concentration of reactive species, accelerating the film growth.

Understanding the Trade-offs

While low temperature is a major benefit, choosing PECVD introduces its own set of considerations. The use of plasma is not a free lunch.

Film Purity and Contamination

The plasma process can incorporate elements from the precursor gases, such as hydrogen, into the deposited film. This contamination can alter the film's electrical or optical properties.

Traditional high-temperature CVD often produces purer films because the high thermal energy is more effective at driving off such impurities, resulting in a cleaner deposit.

Film Density and Structure

The high heat in conventional CVD gives atoms on the surface more energy to move around and settle into an optimal, dense, and often crystalline structure.

PECVD films, deposited at lower temperatures, can sometimes be less dense or more amorphous (less crystalline) because the atoms have less surface mobility during growth.

Process and Equipment Complexity

A PECVD system is inherently more complex than a traditional thermal CVD system. It requires an RF power generator, matching networks, and sophisticated chamber designs to generate and sustain a uniform plasma.

This adds to the equipment cost and maintenance complexity compared to simpler thermal-only systems.

Making the Right Choice for Your Application

Selecting the correct deposition method requires matching the process capabilities to your substrate's limitations and your desired film characteristics.

- If your primary focus is depositing on temperature-sensitive materials: PECVD is your only viable option, as its low process temperature prevents substrate damage.

- If your primary focus is achieving the highest possible film purity and density: Traditional high-temperature CVD is often the superior choice, provided your substrate can withstand the heat.

- If your primary focus is finding a balance of high throughput and good film quality for industrial production: PECVD frequently offers the best compromise, enabling fast deposition at moderate temperatures compatible with many applications.

Ultimately, your decision is governed by balancing the thermal budget of your substrate against the specific performance requirements of the final thin film.

Summary Table:

| Feature | Traditional CVD | PECVD |

|---|---|---|

| Energy Source | High thermal energy (heat) | Plasma (RF field) |

| Typical Temperature Range | 600°C to 800°C+ | Room temperature to 350°C |

| Substrate Compatibility | Heat-resistant materials only | Heat-sensitive materials (e.g., polymers, semiconductors) |

| Film Purity | High, with fewer impurities | May include hydrogen contamination |

| Film Density | Often dense and crystalline | Can be less dense or amorphous |

| Deposition Rate | Lower at same temperature | Higher at lower temperatures |

| Equipment Complexity | Lower | Higher (requires RF systems) |

Need expert guidance on selecting the right furnace for your PECVD or CVD processes? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong in-house R&D and deep customization capabilities. Whether you're working with heat-sensitive substrates or require precise film properties, we can help optimize your lab's efficiency and outcomes. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition