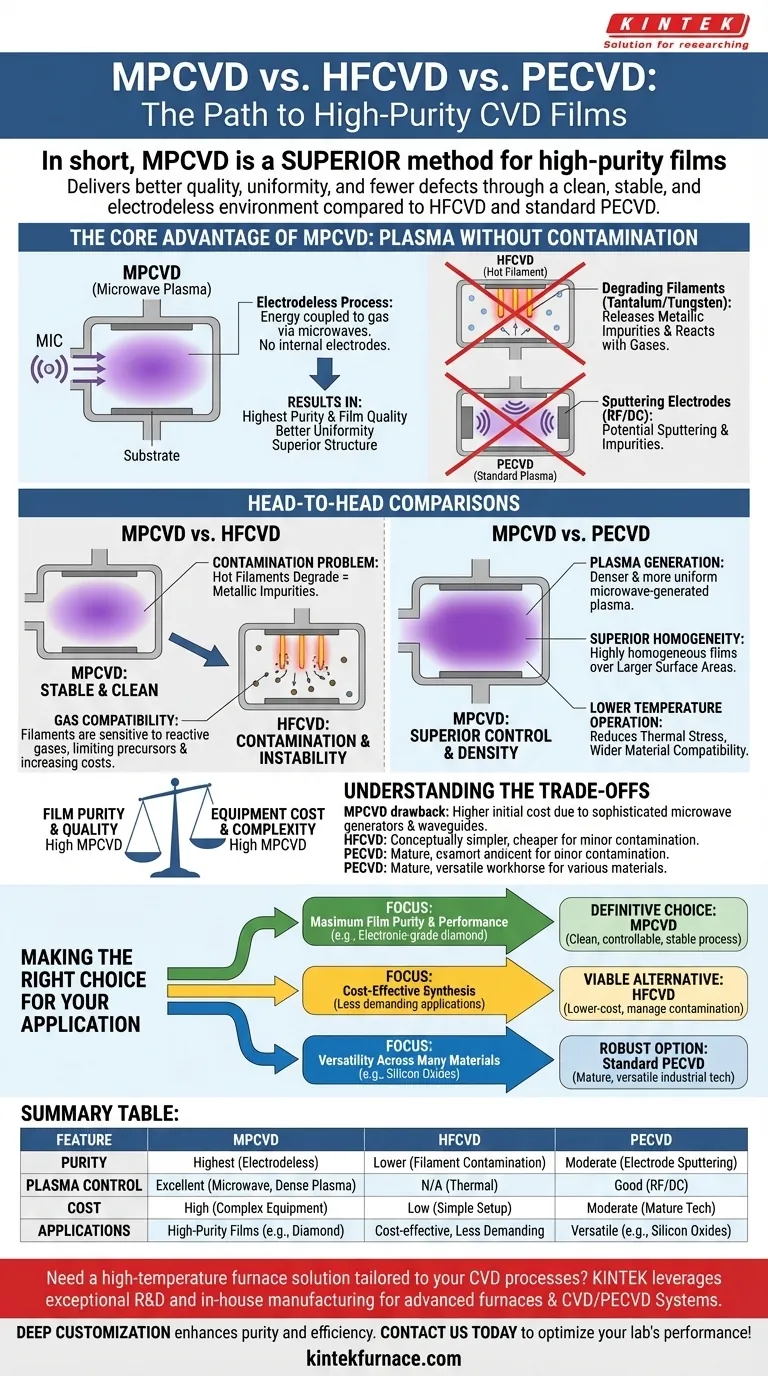

In short, MPCVD is a superior method for growing high-purity films compared to HFCVD and PECVD. Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) creates a cleaner, more stable, and highly controlled environment, resulting in films with better quality, uniformity, and fewer defects than those produced by Hot Filament (HFCVD) or standard Plasma-Enhanced (PECVD) techniques.

The decision between CVD methods hinges on the fundamental trade-off between film purity, process control, and cost. MPCVD excels in producing the highest quality films by eliminating common sources of contamination inherent in other plasma-based techniques.

The Core Advantage of MPCVD: Plasma without Contamination

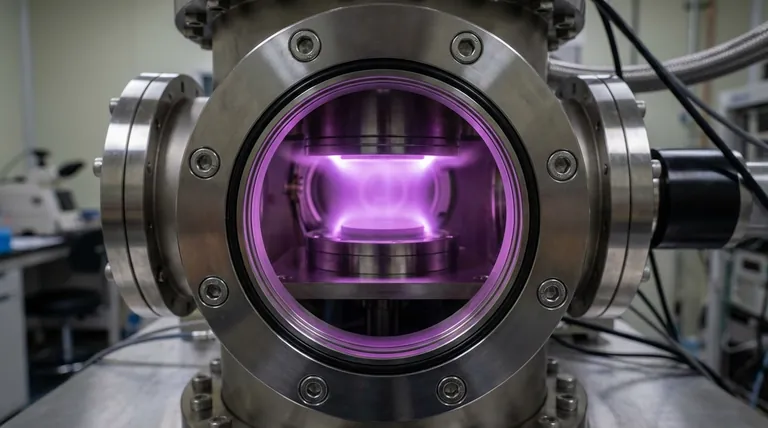

How MPCVD Works

MPCVD uses microwave energy to excite process gases into a plasma state within a vacuum chamber. This process is electrodeless, meaning the energy is coupled into the gas without any physical contact from internal electrodes.

Avoiding Filament and Electrode Impurities

This electrodeless nature is the primary advantage of MPCVD. It completely avoids the two main sources of contamination found in other methods: degrading filaments used in HFCVD and sputtering electrodes used in some forms of PECVD.

Driving Higher Purity and Film Quality

By creating a high-density, stable plasma in a clean environment, MPCVD enables the growth of films—particularly diamond—with superior structural quality, better uniformity over large areas, and higher purity.

Head-to-Head: MPCVD vs. HFCVD

The Contamination Problem in HFCVD

Hot Filament CVD (HFCVD) uses heated wires, typically made of tantalum or tungsten, to thermally break down precursor gases. Over time, these hot filaments degrade and react with the gases, releasing metallic impurities directly into the film.

Gas Compatibility and Process Stability

The filaments in HFCVD are also sensitive to certain reactive gases, which can shorten their lifespan and limit the types of precursors you can use. This degradation increases operational costs and introduces process instability, whereas MPCVD remains stable.

Head-to-Head: MPCVD vs. PECVD

Plasma Generation and Control

While both are plasma-enhanced methods, standard PECVD typically uses a Radio Frequency (RF) or Direct Current (DC) power source. MPCVD's use of microwaves generates a denser and more uniform plasma, providing superior control over the deposition process.

Superior Homogeneity and Area

The controlled, high-density plasma generated by MPCVD facilitates the growth of highly homogenous films over a larger surface area. This is critical for industrial production where consistency is key.

Lower Temperature Operation

MPCVD can often operate at lower substrate temperatures compared to other thermal methods. This reduces thermal stress on the substrate, enabling deposition on a wider range of materials without causing damage.

Understanding the Trade-offs

Equipment Complexity and Cost

The primary drawback of MPCVD is the higher initial cost and complexity of the equipment. Microwave generators, waveguides, and resonant cavities are more sophisticated and expensive than the simpler power supplies and filament setups of PECVD or HFCVD.

Process Simplicity

HFCVD is conceptually simpler and often cheaper to implement, making it a common choice for academic research or applications where minor contamination is tolerable. PECVD is a mature, versatile workhorse used widely for materials other than diamond, such as silicon oxides and nitrides.

Application Specificity

No single method is universally "best." The optimal choice is dictated entirely by the requirements of the final film. For lower-grade coatings, the benefits of MPCVD may not justify the added cost.

Making the Right Choice for Your Application

Choosing the correct deposition technology requires a clear understanding of your end goal.

- If your primary focus is maximum film purity and performance (e.g., electronic-grade diamond): MPCVD is the definitive choice due to its clean, controllable, and stable process.

- If your primary focus is cost-effective synthesis for less demanding applications: HFCVD offers a viable, lower-cost alternative, provided you can manage potential contamination.

- If your primary focus is versatility across many non-diamond materials: Standard PECVD is a robust and mature industrial technology with a wide application space.

Ultimately, selecting the correct CVD method requires aligning the process capabilities with your specific material and performance targets.

Summary Table:

| Feature | MPCVD | HFCVD | PECVD |

|---|---|---|---|

| Purity | Highest (electrodeless) | Lower (filament contamination) | Moderate (electrode sputtering) |

| Plasma Control | Excellent (microwave, dense plasma) | N/A (thermal) | Good (RF/DC) |

| Cost | High (complex equipment) | Low (simple setup) | Moderate (mature tech) |

| Applications | High-purity films (e.g., diamond) | Cost-effective, less demanding | Versatile (e.g., silicon oxides) |

Need a high-temperature furnace solution tailored to your CVD processes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental needs, enhancing purity and efficiency. Contact us today to discuss how we can optimize your lab's performance!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application