At high temperatures, molybdenum disilicide (MoSi2) exhibits exceptional resistance to oxidation by forming a self-healing, protective layer of silicon dioxide (SiO2). This unique characteristic allows it to operate in oxidizing atmospheres at extreme temperatures, up to 1850°C. However, this remarkable thermal stability is accompanied by significant mechanical limitations that are critical to understand.

Molybdenum disilicide's defining high-temperature behavior is the formation of a protective silica film, making it a premier material for electric heating elements. Its utility is governed by a critical trade-off: excellent thermal stability versus poor mechanical strength (creep) above 1200°C and inherent brittleness at lower temperatures.

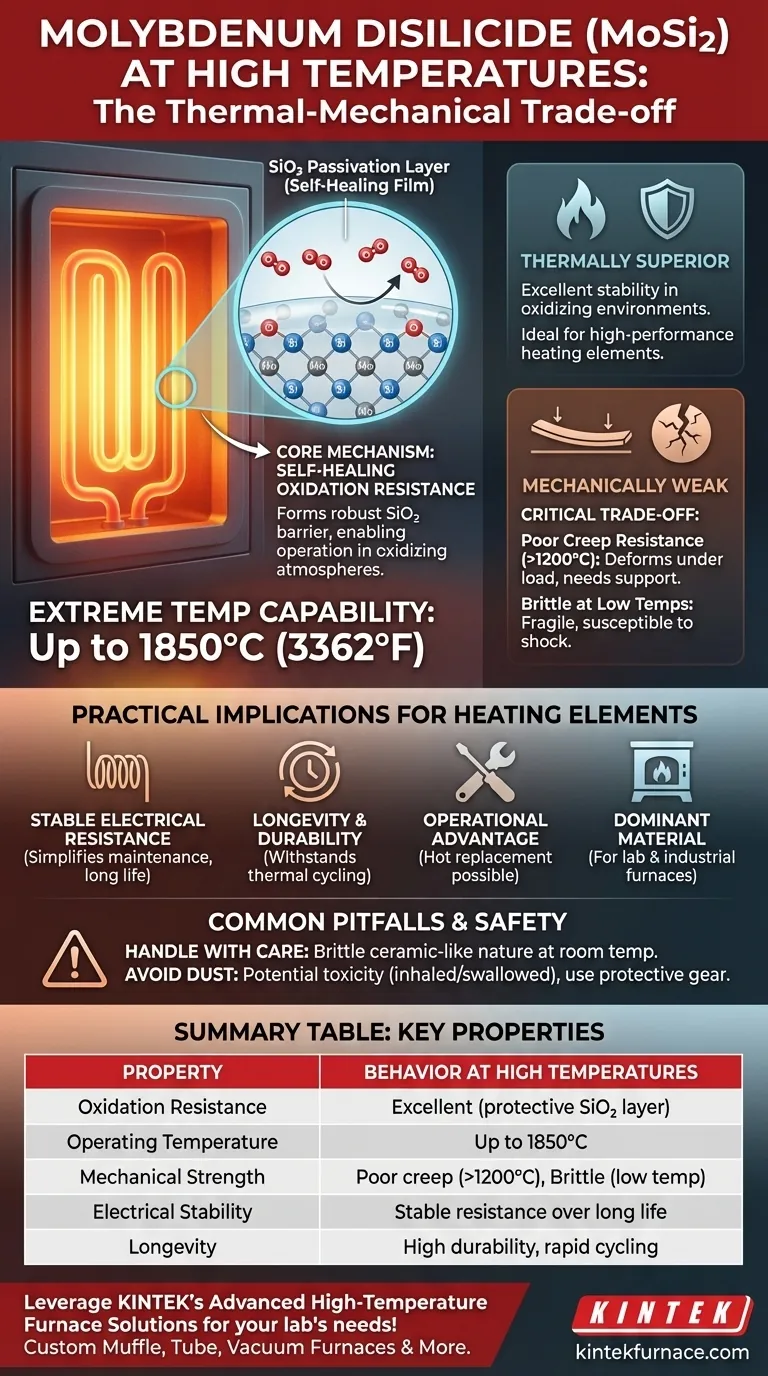

The Core Mechanism: Self-Healing Oxidation Resistance

The key to MoSi2's high-temperature performance lies in a chemical reaction that occurs on its surface when exposed to oxygen.

Formation of the SiO2 Passivation Layer

At elevated temperatures, the silicon within the MoSi2 alloy reacts with oxygen in the atmosphere to form a thin, glassy film of silicon dioxide (SiO2). This passivation layer acts as a robust barrier, protecting the underlying material from further oxidation and degradation.

Performance in Oxidizing Atmospheres

Because this protective SiO2 layer is stable and self-healing, MoSi2 elements thrive in oxidizing environments. This makes them ideal for applications like laboratory furnaces, industrial heat treatment, and glass melting where air is present at high temperatures.

Extreme Temperature Capability

MoSi2 heating elements have the highest operating temperatures among comparable materials, capable of reaching up to 1850°C (3362°F) in service. This is remarkably close to its actual melting point of 2030°C (3686°F), showcasing its incredible thermal stability.

Understanding the Mechanical Trade-offs

While thermally superior, MoSi2 is not a suitable structural material at its highest operating temperatures. Its mechanical properties present significant design constraints.

The Challenge of Creep Deformation

Above approximately 1200°C (2192°F), molybdenum disilicide loses its creep resistance. This means the material will slowly deform and sag under its own weight or any applied mechanical load. Heating elements must be properly supported to prevent this type of failure.

Low-Temperature Brittleness

At room temperature and other lower temperatures, MoSi2 is an extremely brittle ceramic-like material. It is susceptible to fracture from mechanical shock or stress, which demands careful handling and installation.

Practical Implications for Heating Elements

The unique properties of MoSi2 make it a dominant material for high-performance electric heating elements, with several operational advantages.

Stable Electrical Resistance

MoSi2 maintains a stable electrical resistance over its long service life. This allows for new elements to be connected in series with older ones without causing performance issues, simplifying maintenance.

Longevity and Durability

With its self-healing protective layer, MoSi2 offers the longest inherent life of all common electric heating element materials. It also withstands rapid thermal cycling without significant degradation.

Operational Advantages

The robust nature of MoSi2 elements at temperature allows them to be replaced relatively easily, even while a furnace is still hot. This can significantly reduce downtime in industrial settings.

Common Pitfalls and Safety

To use MoSi2 effectively, one must be aware of its physical limitations and handling requirements.

Key Physical Characteristics

Molybdenum disilicide is a gray, metallic-looking solid with a moderate density of 6.26 g/cm³ and a tetragonal crystal structure. Acknowledging its ceramic-like nature at room temperature is key to avoiding damage.

Handling and Safety Precautions

The material itself is listed with hazard statements indicating it can be toxic if swallowed and harmful if inhaled or in contact with skin. When handling MoSi2, especially in powdered form or when dealing with broken elements, you should avoid breathing dust and use appropriate protective clothing.

Making the Right Choice for Your Application

Use these guidelines to determine if MoSi2 is the correct material for your specific goal.

- If your primary focus is maximum heating temperature in an oxidizing environment: MoSi2 is an elite choice due to its stable SiO2 layer, offering the longest life and highest operating temperatures for heating elements.

- If your application involves significant mechanical load above 1200°C: You must avoid using MoSi2 as a structural component, as its poor creep resistance will lead to deformation and failure.

- If you require a material with high toughness at room temperature: MoSi2 is unsuitable due to its inherent brittleness, which requires careful handling and installation procedures to prevent fracture.

Ultimately, leveraging MoSi2 successfully means designing around its mechanical weaknesses to exploit its unparalleled thermal stability.

Summary Table:

| Property | Behavior at High Temperatures |

|---|---|

| Oxidation Resistance | Excellent; forms protective SiO2 layer, self-healing in oxidizing atmospheres |

| Operating Temperature | Up to 1850°C, close to melting point of 2030°C |

| Mechanical Strength | Poor creep resistance above 1200°C; brittle at lower temperatures |

| Electrical Stability | Stable resistance over long service life |

| Longevity | High durability with rapid thermal cycling capability |

Leverage KINTEK's advanced high-temperature furnace solutions for your lab's needs! With exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for unique experimental requirements, enhancing efficiency and performance. Contact us today to discuss how we can support your high-temperature applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments