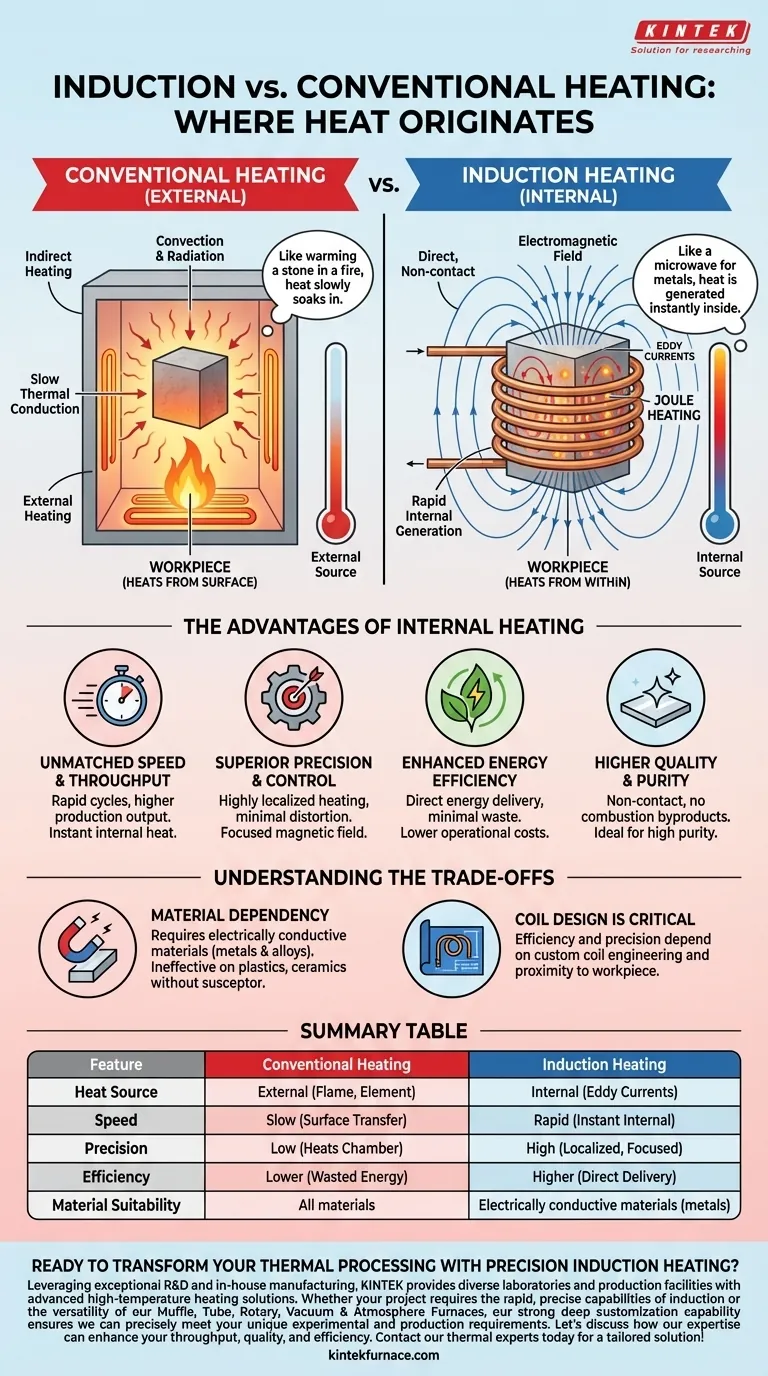

The fundamental difference between induction and conventional heating is where the heat originates. Conventional methods, like a gas or electric furnace, rely on external heat sources that use convection and radiation to slowly warm a material's surface. In stark contrast, induction heating uses a magnetic field to generate heat directly inside the material itself, bypassing the slow process of external heat transfer.

While conventional heating relies on slow, external heat transfer, induction heating acts like a microwave for metals, generating rapid, precise, and efficient heat from within the material. This core difference drives significant advantages in speed, control, and overall process quality.

The Core Mechanism: Internal vs. External Heat Generation

To truly grasp the implications, you must understand the physics behind each method. The approach to delivering thermal energy dictates the efficiency, speed, and final quality of the process.

How Conventional Furnaces Work (Convection & Radiation)

Conventional methods are indirect. A gas flame or an electric heating element first heats the chamber of the furnace.

This heat is then transferred to the surface of the workpiece through convection (movement of hot air) and radiation (infrared energy).

Finally, the heat must slowly travel from the surface to the core of the material via thermal conduction. This is often the slowest and least efficient part of the process.

How Induction Heating Works (Electromagnetic Induction)

Induction heating is a direct, non-contact process. An alternating current is passed through an induction coil, creating a powerful and rapidly changing magnetic field.

When an electrically conductive workpiece is placed within this field, it induces circulating electrical currents, known as eddy currents, inside the material.

The material’s natural electrical resistance opposes these currents, resulting in intense and instantaneous heat generation (Joule heating). The heat originates within the workpiece itself.

The Practical Advantages of Internal Heating

Generating heat internally is not just a novelty; it provides transformative benefits that are critical for modern industrial and research applications.

Unmatched Speed and Throughput

Because heat is generated instantly and internally, processing times are dramatically reduced compared to waiting for heat to soak in from an external source.

This leads directly to faster production cycles and a significant increase in output, making it ideal for high-volume manufacturing.

Superior Precision and Control

The magnetic field can be precisely focused by the shape and design of the induction coil.

This allows for highly localized heating, enabling processes like surface hardening a gear tooth without softening the core or brazing a joint without damaging nearby sensitive components.

Enhanced Energy Efficiency

Energy is delivered directly to the workpiece where it is needed. Very little energy is wasted heating the surrounding atmosphere or the walls of a furnace.

This direct transfer results in significantly higher energy efficiency and, consequently, lower operational energy bills.

Higher Quality and Purity

As a non-contact method, the workpiece never touches a flame or a heating element. This completely eliminates the risk of contamination from combustion byproducts or contact materials.

This is essential for applications requiring high purity, such as melting medical-grade alloys or processing materials in a vacuum or inert atmosphere.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Understanding its limitations is key to making an objective decision.

Material Dependency

Induction heating's primary requirement is that the target material must be electrically conductive. It works exceptionally well for metals and alloys.

It is ineffective for heating non-conductive materials like most plastics, glass, or ceramics unless they are paired with a conductive "susceptor" that gets hot and transfers heat conventionally.

Coil Design is Critical

The efficiency and precision of the process are entirely dependent on the design of the induction coil and its proximity to the workpiece.

Many applications require custom-engineered coils to achieve the desired heating pattern, which adds a layer of specific engineering to the setup.

Making the Right Choice for Your Goal

The choice between induction and conventional heating depends entirely on your project's priorities.

- If your primary focus is maximum throughput and speed: Induction heating's rapid, internal heat generation is almost always the superior choice.

- If your primary focus is process control and product quality: The precision and non-contact nature of induction minimize defects, thermal distortion, and contamination.

- If your primary focus is low initial cost for general-purpose bulk heating: A conventional furnace may be a more economical starting point, especially if your materials are not conductive.

Ultimately, understanding that induction heats from the inside out is the key to leveraging its transformative potential for your specific application.

Summary Table:

| Feature | Conventional Heating | Induction Heating |

|---|---|---|

| Heat Source | External (flame, element) | Internal (eddy currents) |

| Speed | Slow (heat transfer from surface) | Rapid (instant internal generation) |

| Precision | Low (heats entire chamber) | High (localized, focused heating) |

| Efficiency | Lower (energy wasted heating air/chamber) | Higher (energy delivered directly to part) |

| Material Suitability | All materials | Electrically conductive materials (metals) |

Ready to Transform Your Thermal Processing with Precision Induction Heating?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and production facilities with advanced high-temperature heating solutions. Whether your project requires the rapid, precise capabilities of induction or the versatility of our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, our strong deep customization capability ensures we can precisely meet your unique experimental and production requirements.

Let's discuss how our expertise can enhance your throughput, quality, and efficiency. Contact our thermal experts today for a tailored solution!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance