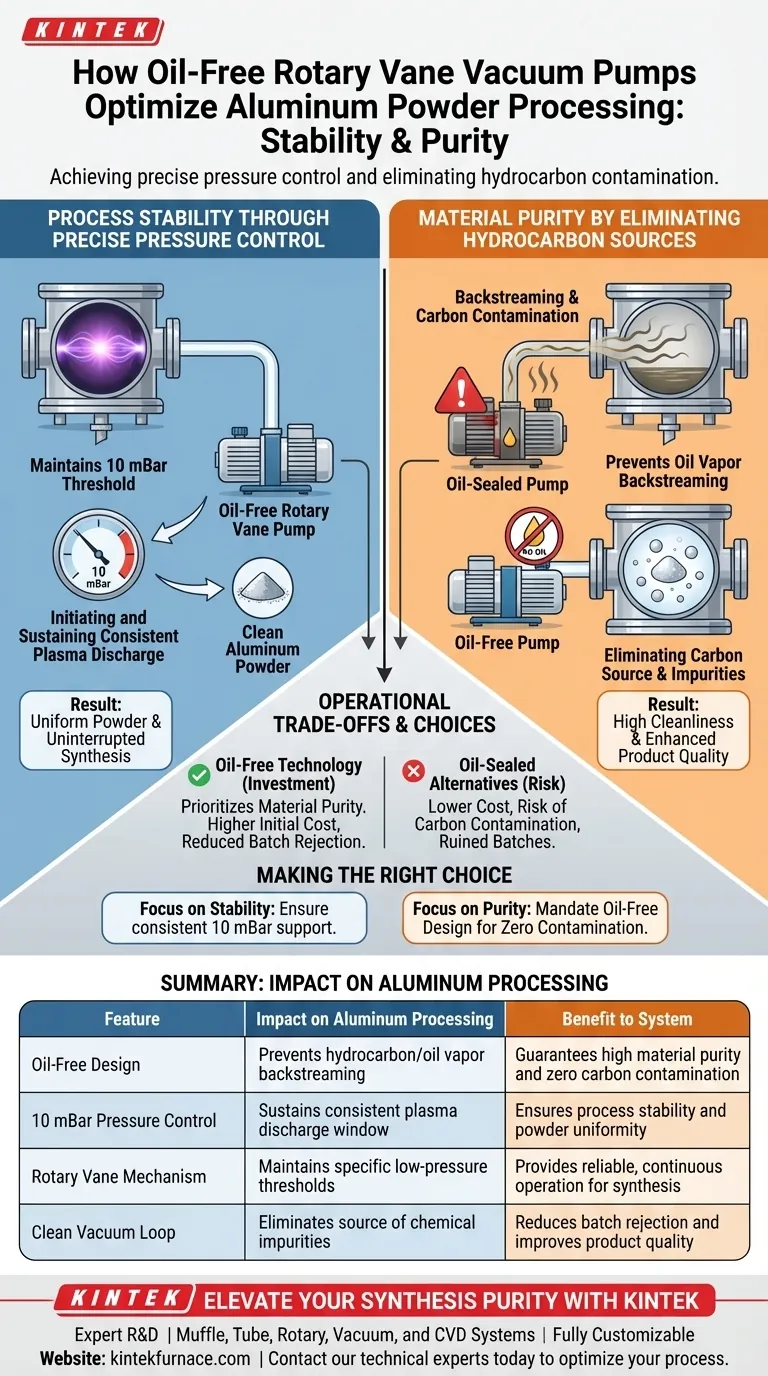

The contribution of an oil-free rotary vane vacuum pump to aluminum powder processing is twofold: it secures process stability through precise pressure control and guarantees material purity by eliminating hydrocarbon sources. By maintaining a system pressure of approximately 10 mBar, the pump enables stable plasma discharge while simultaneously preventing oil vapor backstreaming, which is the primary cause of carbon contamination in high-purity synthesis.

Stability in aluminum powder processing relies on consistent plasma discharge, while purity depends on a contaminant-free environment. An oil-free pump solves both challenges simultaneously by holding steady pressure at 10 mBar and completely eliminating hydrocarbon sources from the vacuum loop.

The Role of Pressure in Process Stability

To achieve a consistent reaction, the vacuum environment must be rigorously controlled. The oil-free rotary vane pump is the active component responsible for creating the specific conditions required for plasma generation.

Initiating Plasma Discharge

The processing system relies on a stable plasma discharge to function correctly. This physical state can only be initiated and sustained within a specific low-pressure window.

Maintaining the 10 mBar Threshold

The pump is engineered to maintain the reaction system at a vacuum level of approximately 10 mBar. Deviating from this pressure level could destabilize the plasma, interrupting the synthesis process and compromising the uniformity of the aluminum powder.

Ensuring Purity Through Oil-Free Design

While pressure control ensures the process runs, the type of pump used determines the quality of the final product. In high-purity applications, the presence of pump oil is a critical liability.

Preventing Vapor Backstreaming

Standard vacuum pumps often release oil vapors that migrate backward into the reaction chamber, a phenomenon known as backstreaming. An oil-free design mechanically eliminates this risk at the source.

Eliminating Carbon Contamination

Oil vapors act as a carbon source, which reacts negatively with aluminum during synthesis. By removing oil from the pumping mechanism, you avoid introducing carbon contaminants, ensuring the high cleanliness of the aluminum powder and subsequent synthesis products.

Understanding the Operational Trade-offs

While the benefits of an oil-free system are clear for purity, it is important to understand the operational constraints involved in this specific application.

The Necessity of Specific Pressure

The system is tuned specifically for the 10 mBar range. The vacuum pump must be sized and maintained to hold this specific pressure against the process load; a pump that pulls a vacuum too deep or not deep enough will fail to sustain the plasma discharge required for the reaction.

Contamination vs. Equipment Cost

Oil-free technology is often an investment made specifically to prioritize material purity. Using cheaper, oil-sealed alternatives is generally not a viable trade-off in this context, as the cost of ruined batches due to carbon contamination far outweighs the savings on equipment.

Making the Right Choice for Your Goal

When selecting vacuum equipment for aluminum powder synthesis, your decision should be driven by the strict requirements of plasma stability and chemical purity.

- If your primary focus is Process Stability: Ensure your pump is rated to consistently maintain a 10 mBar load to support uninterrupted plasma discharge.

- If your primary focus is Material Purity: Mandate an oil-free design to completely eliminate the risk of carbon contamination via backstreaming.

Ultimately, the oil-free rotary vane pump is not just an accessory, but a critical control point for ensuring the integrity of your aluminum powder synthesis.

Summary Table:

| Feature | Impact on Aluminum Processing | Benefit to System |

|---|---|---|

| Oil-Free Design | Prevents hydrocarbon/oil vapor backstreaming | Guarantees high material purity and zero carbon contamination |

| 10 mBar Pressure Control | Sustains consistent plasma discharge window | Ensures process stability and powder uniformity |

| Rotary Vane Mechanism | Maintains specific low-pressure thresholds | Provides reliable, continuous operation for synthesis |

| Clean Vacuum Loop | Eliminates source of chemical impurities | Reduces batch rejection and improves product quality |

Elevate Your Synthesis Purity with KINTEK

Don’t let carbon contamination compromise your high-purity aluminum powder. KINTEK provides high-performance vacuum solutions and laboratory equipment engineered for precision and cleanliness. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific pressure and purity requirements.

Ready to optimize your process stability? Contact our technical experts today to find the perfect vacuum system for your unique needs.

Visual Guide

References

- Alexander Logunov, Sergey S. Suvorov. Plasma–Chemical Low-Temperature Reduction of Aluminum with Methane Activated in Microwave Plasma Discharge. DOI: 10.3390/met15050514

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the role of a laboratory oven in the pre-treatment of Date Palm Stones? Enhance Torrefaction & Grinding Efficiency

- How does excessive gas purging rate affect the alumina furnace tube? Prevent Cracking and Extend Tube Life

- What role does a high-density MgO crucible play in slag reduction experiments? Ensure Pure Results at 1600°C

- How do alumina ceramic furnace tubes compare to other materials like quartz or silicon carbide? Choose the Best for Your High-Temp Needs

- What are the functions of a tungsten wire basket and a quartz crucible? Enhancing Purity in Vacuum Evaporation

- What key functions do graphite molds serve during the hot press sintering? Enhance Ti/Al2O3 Composite Quality

- Why is a graphite crucible used for melting Al-Mg-Si alloys? Superior Purity & Thermal Efficiency

- Why is a stainless steel closed-end tube required for controlled atmospheric experiments? Ensure Precise Material Purity