An industrial vacuum heat treatment furnace facilitates performance adjustment by providing a precisely controlled annealing environment that targets the sub-beta-transus region of the titanium alloy. This process eliminates the internal stresses caused by manufacturing and fundamentally alters the metal's microstructure to suit biomechanical applications.

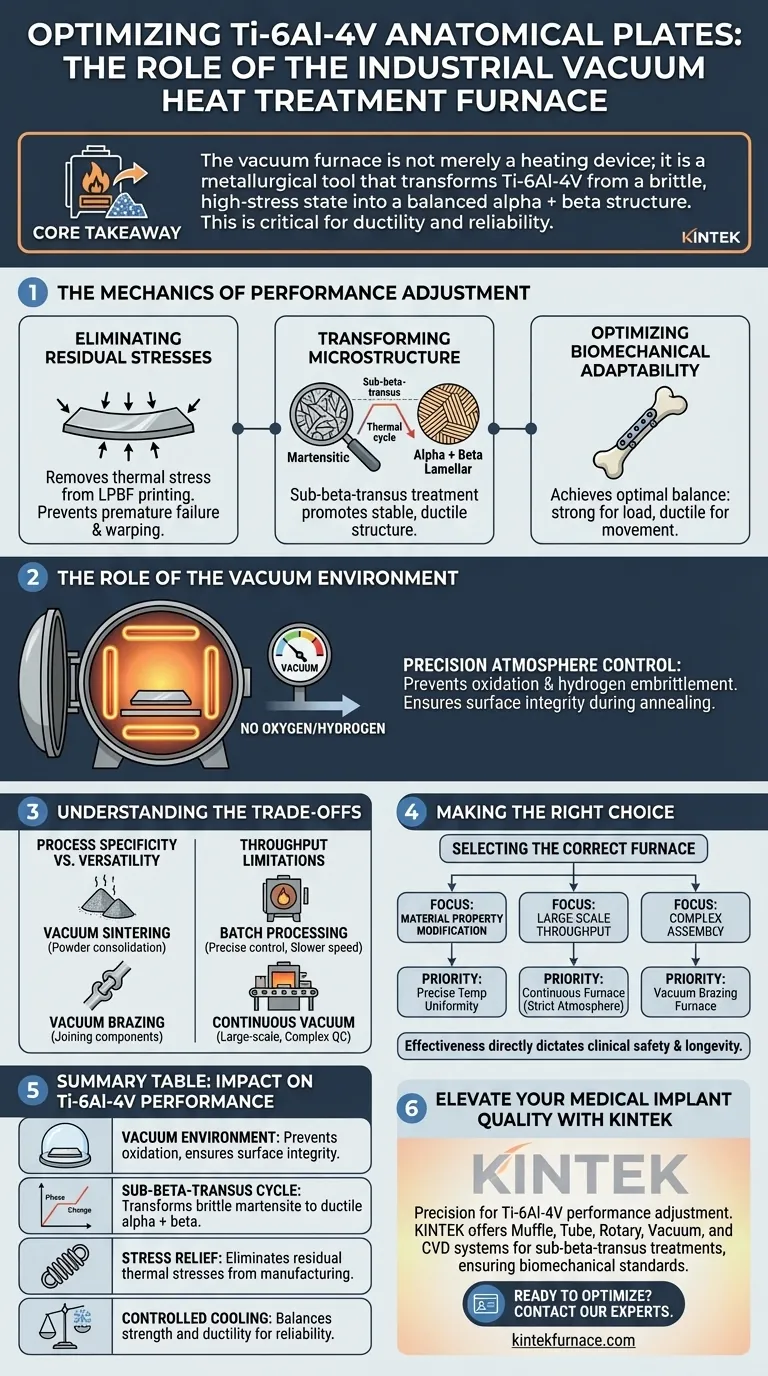

Core Takeaway The vacuum furnace is not merely a heating device; it is a metallurgical tool that transforms Ti-6Al-4V from a brittle, high-stress state into a balanced alpha + beta structure. This transformation is critical for ensuring the ductility and reliability necessary for human anatomical plates.

The Mechanics of Performance Adjustment

Eliminating Residual Stresses

The primary function of the furnace in this context is the removal of residual stresses.

Ti-6Al-4V plates manufactured via Laser Powder Bed Fusion (LPBF) accumulate significant thermal stress during the rapid cooling of the printing process.

By subjecting these plates to high temperatures in a vacuum, the furnace relaxes the material, mitigating the risk of premature failure or warping after implantation.

Transforming the Microstructure

Performance adjustment is largely a result of changing the metal's internal phase structure.

The furnace facilitates a sub-beta-transus heat treatment, which is a specific thermal cycle below the beta-transus temperature.

This promotes the transformation of the initial martensitic structure—which is hard but brittle—into a more stable alpha + beta lamellar structure.

Optimizing Biomechanical Adaptability

The shift in microstructure directly impacts how the plate interacts with the human body.

The alpha + beta structure achieves an optimal balance between strength and ductility.

This ensures the anatomical plate is strong enough to support bone load but ductile enough to withstand physiological movement without fracturing.

The Role of the Vacuum Environment

Precision Atmosphere Control

The "vacuum" aspect of the furnace is as critical as the temperature.

It creates a pristine environment that prevents the titanium from reacting with oxygen or hydrogen at high temperatures.

This ensures the surface integrity of the anatomical plate remains uncompromised during the lengthy annealing process.

Understanding the Trade-offs

Process Specificity vs. Versatility

While vacuum heat treatment is essential for performance, the equipment must match the production scale.

A vacuum sintering furnace is often better suited for processing metal powders or initial consolidation.

Conversely, a vacuum brazing furnace is specialized for joining components rather than altering bulk material properties.

Throughput Limitations

Achieving the precise alpha + beta structure requires strict adherence to thermal cycles, which can limit production speed.

Continuous vacuum furnaces offer a solution for large-scale production requiring ongoing treatment.

However, utilizing a continuous process may require more complex quality control measures compared to batch processing to ensure every plate receives the exact sub-beta-transus treatment.

Making the Right Choice for Your Production

To select the correct furnace for Ti-6Al-4V adjustment, you must align the equipment capabilities with your specific manufacturing goals.

- If your primary focus is material property modification: Prioritize a furnace with precise temperature uniformity to strictly control the sub-beta-transus cycle for optimal alpha + beta transformation.

- If your primary focus is large-scale throughput: Consider continuous vacuum furnaces, provided they can maintain the strict atmosphere control required for medical-grade titanium.

- If your primary focus is complex assembly: Evaluate vacuum brazing furnaces if the plates require joining with other precision metal components.

The effectiveness of your heat treatment directly dictates the clinical safety and longevity of the final implant.

Summary Table:

| Feature | Impact on Ti-6Al-4V Performance |

|---|---|

| Vacuum Environment | Prevents oxidation and hydrogen embrittlement; ensures surface integrity. |

| Sub-beta-transus Cycle | Transforms brittle martensite into a ductile alpha + beta lamellar structure. |

| Stress Relief | Eliminates residual thermal stresses from manufacturing (e.g., LPBF). |

| Controlled Cooling | Balances strength and ductility for biomechanical reliability. |

Elevate Your Medical Implant Quality with KINTEK

Precision is non-negotiable when adjusting the performance of Ti-6Al-4V anatomical plates. At KINTEK, we understand that the reliability of a medical implant depends on perfect metallurgical control.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our industrial vacuum furnaces are specifically designed to provide the precise temperature uniformity and high-vacuum atmospheres required for sub-beta-transus heat treatments. Whether you need batch processing for high-value implants or customizable high-temp furnaces for unique R&D needs, our equipment ensures your materials meet the highest biomechanical standards.

Ready to optimize your heat treatment process? Contact our technical experts today to discover how our customizable furnace solutions can enhance your production efficiency and product safety.

Visual Guide

References

- Soumyabrata Basak, Dong-Hyun Kim. Modification of Mechanical Properties of Ti–6Al–4V Using L-PBF for Anatomical Plates. DOI: 10.3390/met15010032

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What industries benefit from using drop-bottom quench furnaces? Achieve Metallurgical Precision for Aerospace and Automotive

- What are the advantages of vacuum heat treatment? Achieve Superior Cleanliness and Performance for Critical Parts

- What are the primary applications of a vacuum heat treatment furnace? Achieve Superior Metallurgical Outcomes

- What is sinter used for in blast furnace? The Engineered Feed for Peak Efficiency

- How does high-temperature sintering furnace setting influence BaTiO3 microstructure? Optimize Sputtering Performance

- What are the main structural components of a vacuum sintering furnace? Unlock Precision in High-Temperature Processing

- What are the tool and die industry applications of furnace brazing? Boost Performance and Cut Costs

- How does vacuum level control affect ceramic sintering? Master High-Precision Material Performance