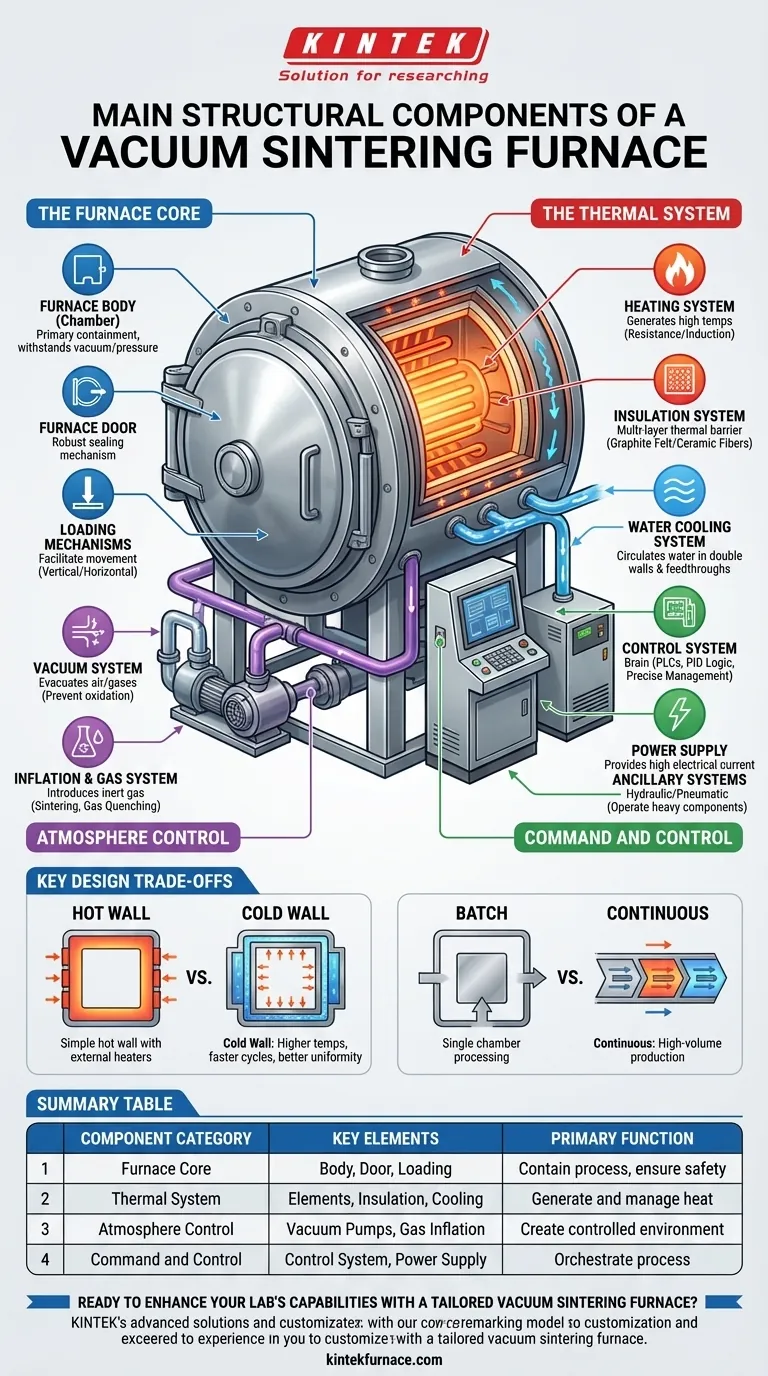

At its core, a vacuum sintering furnace is an integrated system where multiple structural components work in concert to create a highly controlled environment. The main components can be grouped into the furnace chamber itself, the systems that generate and manage heat, the systems that control the atmosphere, and the overarching control and power infrastructure that orchestrates the entire process.

Understanding a vacuum sintering furnace is not about memorizing a list of parts, but about seeing how these distinct systems—structural, thermal, and atmospheric—unite to transform powdered materials into solid, high-performance components under precise control.

The Furnace Core: Containing the Process

The physical structure of the furnace is designed to contain extreme temperatures and pressures while allowing for the safe handling of materials.

The Furnace Body and Door

The furnace body, or chamber, is the primary containment vessel. It is engineered to withstand the deep vacuum and, in some cases, the positive pressure of backfilled gas.

The furnace door provides access to the chamber and is critical for process integrity. A robust sealing mechanism is essential to maintain the vacuum and prevent atmospheric contamination.

Loading and Unloading Mechanisms

These systems facilitate the movement of workpieces into and out of the furnace. Designs can be vertical loading, where parts are lowered in from the top, or horizontal loading, where they are pushed in from the side on a tray or worktable.

The Thermal System: Generating and Managing Heat

This group of components is responsible for creating, containing, and removing heat according to a precise temperature profile.

The Heating System

This is the heart of the furnace, responsible for generating the high temperatures required for sintering. Common types include resistance heating elements, often made of tungsten or graphite, or induction heating systems, which use electromagnetic fields to heat the material.

The Insulation System

A multi-layer thermal insulation package, often using graphite felt or advanced ceramic fibers, surrounds the heating zone. Its purpose is to minimize heat loss, improve temperature uniformity, and protect the furnace body from extreme temperatures.

The Water Cooling System

This system circulates water through the double walls of the furnace body and around power feedthroughs. It is essential in "cold wall" designs to keep the outer vessel at a safe temperature and to enable rapid cooling of the product at the end of the cycle.

Atmosphere Control: Mastering the Environment

The ability to manipulate the atmosphere inside the furnace is what defines vacuum processing.

The Vacuum System

A combination of pumps works to evacuate air and other gases from the furnace chamber. This removes reactive elements like oxygen, preventing oxidation and creating the clean environment necessary for high-quality sintering.

The Inflation & Gas System

This system allows for the introduction of a specific gas, typically an inert gas like argon or nitrogen. It can be used to perform sintering under a partial pressure, control reactions, or to initiate rapid "gas quenching" for accelerated cooling.

Command and Control: Ensuring Precision

These systems provide the intelligence and power to run the entire operation safely and repeatably.

The Control System

This is the brain of the furnace. Modern systems use a combination of PLCs and computer interfaces to precisely manage every process parameter, including temperature ramps, vacuum levels, and cycle timing, often using PID (Proportional-Integral-Derivative) logic for accuracy.

The Power Supply

This system provides the high electrical current needed to run the heating elements. For induction furnaces, this is often an intermediate frequency power supply specifically designed to drive the induction coil.

Ancillary Systems (Hydraulic/Pneumatic)

Many furnaces use hydraulic or pneumatic systems to operate heavy components like doors, clamps, and loading mechanisms with significant force and precision.

Understanding Key Design Trade-offs

The specific configuration of these components involves critical trade-offs that determine the furnace's capabilities and cost.

Hot Wall vs. Cold Wall Design

A hot wall furnace has heating elements outside the vacuum chamber, heating the entire vessel. This is simpler but limited in maximum temperature.

A cold wall furnace has the heating elements and insulation inside the vacuum chamber, while the chamber wall is actively cooled. This design allows for much higher temperatures, faster heating/cooling cycles, and better temperature uniformity.

Batch vs. Continuous Furnaces

A batch furnace processes one load at a time, offering high flexibility for different part types and process cycles.

A continuous furnace moves parts through different temperature zones in a constant flow. This design is built for high-volume production of a single type of part, maximizing throughput at the cost of flexibility.

Making the Right Choice for Your Goal

Selecting the right configuration depends entirely on your specific material and production requirements.

- If your primary focus is high-temperature materials and rapid cycles: A cold-wall furnace with advanced insulation and a powerful gas quench system is the superior choice.

- If your primary focus is process versatility for R&D: A batch-style furnace with a sophisticated control system for precise atmospheric and thermal management is essential.

- If your primary focus is high-volume, standardized production: A continuous furnace design will provide the most efficient and cost-effective throughput.

By viewing the furnace as an interconnected system, you can better diagnose issues, optimize processes, and make informed decisions.

Summary Table:

| Component Category | Key Elements | Primary Function |

|---|---|---|

| Furnace Core | Body, Door, Loading Mechanisms | Contain process, ensure safety and integrity |

| Thermal System | Heating Elements, Insulation, Water Cooling | Generate and manage heat for sintering |

| Atmosphere Control | Vacuum Pumps, Gas Inflation | Create controlled environment, prevent oxidation |

| Command and Control | Control System, Power Supply, Ancillary Systems | Orchestrate process with precision and safety |

Ready to enhance your lab's capabilities with a tailored vacuum sintering furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your unique experimental needs are met precisely. Contact us today to discuss how we can optimize your sintering processes and boost efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement