In short, the industries that benefit most from drop-bottom quench furnaces are those requiring the highest level of metallurgical precision and performance, primarily aerospace, automotive, and high-end manufacturing. These furnaces are chosen when the mechanical properties of a metal component, such as strength, hardness, and fatigue resistance, are absolutely critical to its function and safety.

The core value of a drop-bottom quench furnace isn't just heat treating; it's the ability to transfer a part from a high-heat environment to a quenching liquid with extreme speed and uniformity. This capability is essential for developing superior and highly consistent material properties that other methods cannot reliably achieve.

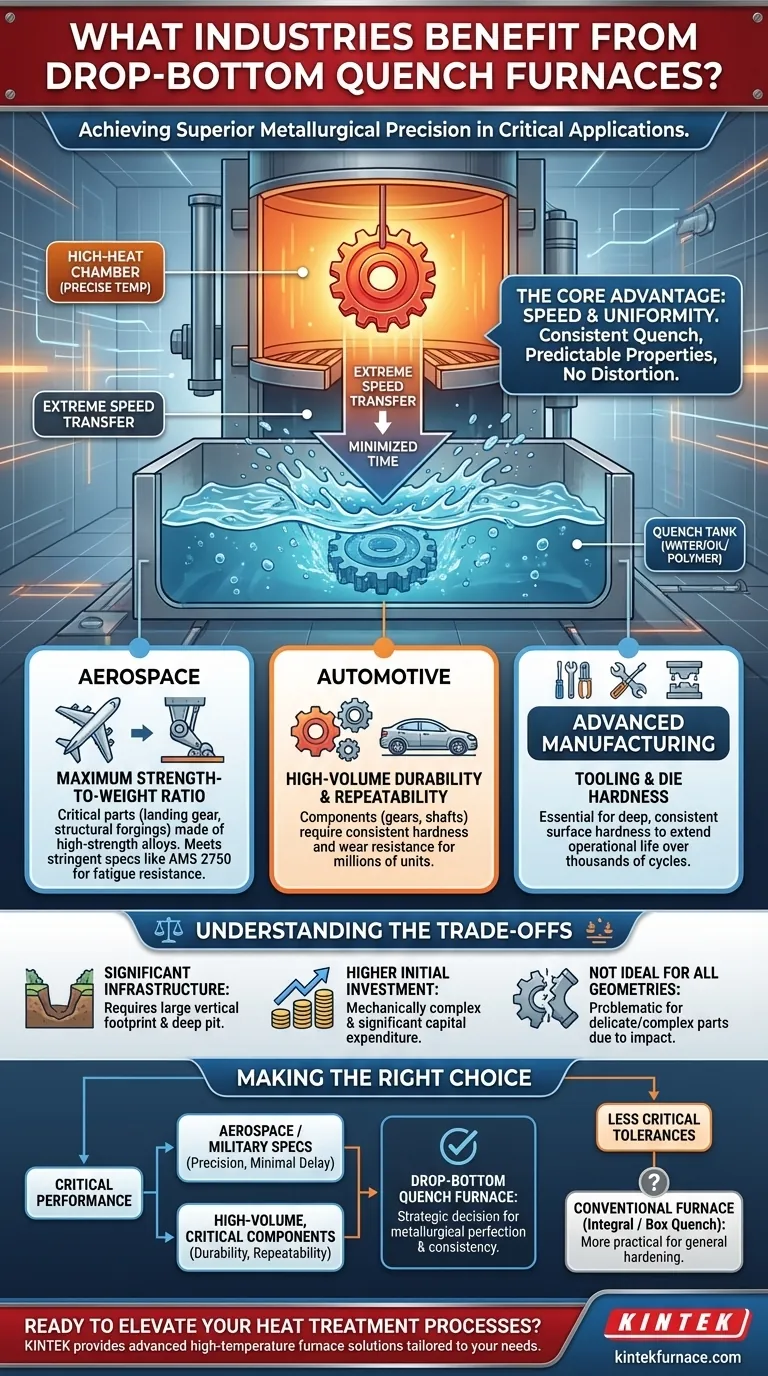

The Core Advantage: Speed and Uniformity

A drop-bottom quench furnace operates on a simple but powerful principle. A part is heated to a precise temperature in an upper chamber, after which the furnace floor, or "bottom," opens, rapidly dropping the part into a quench tank of water, oil, or polymer located directly below. This design delivers two key advantages.

Minimizing Transfer Time

The primary benefit is the extremely short time between the heating and quenching phases. In conventional furnace setups, a part must be manually or robotically moved from the furnace to a separate quench tank, exposing it to cooler air for several seconds.

This exposure causes heat loss and surface oxidation. The drop-bottom design minimizes this transfer time to just a few seconds, ensuring the part enters the quench medium at its optimal temperature.

Achieving a Consistent Quench

Because the entire component is submerged almost instantly and at a uniform temperature, the cooling process is far more consistent across the part's geometry. This prevents internal stresses, distortion, and warping that can occur with a slower, less uniform quench.

The result is a component with predictable, homogenous mechanical properties, which is a non-negotiable requirement for high-performance applications.

Why These Specific Industries Rely on This Technology

The precision offered by drop-bottom furnaces directly addresses the core challenges of industries where component failure is not an option.

Aerospace: Maximum Strength-to-Weight Ratio

Aerospace components, from landing gear to structural forgings, are often made from high-strength aluminum and steel alloys. To achieve their maximum potential strength, these alloys require precise solution heat treating and rapid quenching.

A slow transfer would compromise the final properties, potentially reducing fatigue resistance and overall strength. Drop-bottom furnaces ensure these critical parts meet stringent aerospace specifications (like AMS 2750) every time.

Automotive: High-Volume Durability and Repeatability

In the automotive industry, components like gears, bearings, shafts, and structural frame parts must be durable and perform consistently across millions of units.

Drop-bottom furnaces provide the process control and repeatability needed for mass production. This ensures that every part has the required hardness and wear resistance to withstand the long-term stresses of vehicle operation.

Advanced Manufacturing: Tooling and Die Hardness

For general manufacturing, particularly in the creation of tools, dies, and molds, surface hardness is paramount. These items must resist wear and deformation over thousands of cycles.

The rapid, uniform quench from a drop-bottom furnace is ideal for creating a deep and consistent hardness layer on these critical manufacturing assets, extending their operational life and ensuring product quality.

Understanding the Trade-offs

While powerful, this technology is not the default solution for all heat-treating needs. It involves specific considerations.

Significant Infrastructure Requirements

These furnaces have a large vertical footprint. The design requires a deep pit to be excavated beneath the furnace to house the quench tank, making installation more complex and costly than for a standard box furnace.

Higher Initial Investment

Drop-bottom furnace systems are mechanically complex and represent a significant capital expenditure. Their cost is typically justified only when the metallurgical requirements for the end product are exceptionally demanding.

Not Ideal for All Part Geometries

The "drop" action can be problematic for very delicate or complex parts that could be damaged by the impact with the quenching liquid or for parts that might trap air and cause an uneven quench. Part racking and handling must be carefully engineered.

Making the Right Choice for Your Application

Choosing the right heat treatment process depends entirely on the performance requirements of your component.

- If your primary focus is meeting stringent aerospace or military specifications: The precision and minimal quench delay of a drop-bottom furnace are essential.

- If your primary focus is producing high-volume, critical components with maximum durability and repeatability: The process control of a drop-bottom furnace justifies the investment.

- If your primary focus is general-purpose hardening with less critical tolerances: A more conventional and less expensive integral or box quench furnace is often a more practical solution.

Ultimately, selecting a drop-bottom quench furnace is a strategic decision to prioritize metallurgical perfection and process consistency above all else.

Summary Table:

| Industry | Key Benefits |

|---|---|

| Aerospace | Maximizes strength-to-weight ratio, meets stringent specs (e.g., AMS 2750) |

| Automotive | Ensures high-volume durability, repeatability, and wear resistance |

| Advanced Manufacturing | Extends tool and die life with deep, consistent hardness |

Ready to elevate your heat treatment processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, automotive, or high-end manufacturing, we can help you achieve superior metallurgical outcomes. Contact us today to discuss how our furnaces can benefit your operations!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process