Fundamentally, a vacuum heat treatment furnace is used for critical thermal processes like annealing, tempering, hardening, and brazing on materials where surface chemistry and integrity are paramount. It excels at treating alloy steels, tool steels, stainless steels, superalloys, and other high-performance mechanical parts by executing these processes in a highly controlled, oxygen-free environment.

The true value of a vacuum furnace is not just the heat treatments it can perform, but the superior metallurgical outcomes it enables. By eliminating atmospheric contamination, it produces parts that are brighter, cleaner, and possess more reliable mechanical properties than those from conventional furnaces.

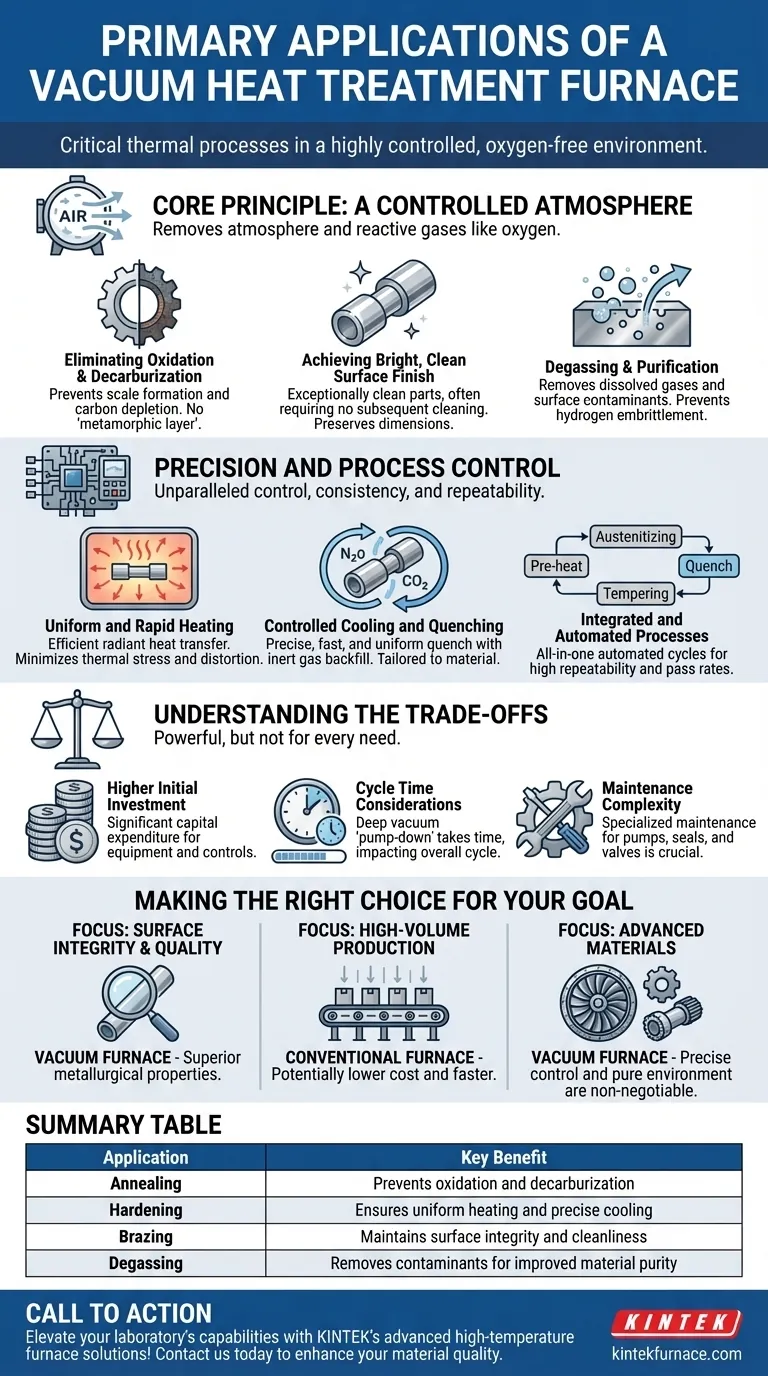

The Core Principle: A Controlled Atmosphere

The defining feature of a vacuum furnace is its ability to remove the atmosphere—and its reactive gases like oxygen—from the heating chamber. This single capability is the source of its most significant advantages.

Eliminating Oxidation and Decarburization

When steel is heated in the presence of oxygen, a layer of oxide scale forms on its surface. Simultaneously, the carbon content at the surface can be depleted, a phenomenon known as decarburization, which softens the material.

A vacuum furnace completely prevents both of these reactions. By operating in a near-vacuum, it ensures parts emerge from the heat-treat cycle without any detrimental surface scale or a carbon-depleted "metamorphic layer."

Achieving a Bright, Clean Surface Finish

A direct result of preventing oxidation is an exceptionally clean and bright surface finish. Parts treated in a vacuum often require no subsequent cleaning, blasting, or pickling operations.

This not only saves time and reduces costs but also preserves the precise dimensions of the finished component.

Degassing and Purification

The vacuum environment actively pulls contaminants, such as dissolved gases like hydrogen and nitrogen, out of the material itself. This degassing function is critical for preventing issues like hydrogen embrittlement in sensitive alloys.

It also vaporizes and removes surface oils and other residues, acting as a final cleaning step that ensures a pure material condition for the heat treatment.

Precision and Process Control

Beyond the clean environment, modern vacuum furnaces offer an unparalleled level of process control, ensuring repeatability and adherence to tight specifications.

Uniform and Rapid Heating

In a vacuum, radiant heat transfer is highly efficient and uniform, ensuring the entire workpiece reaches the target temperature consistently. This minimizes thermal stress and potential distortion.

Controlled Cooling and Quenching

After soaking at temperature, the part must be cooled at a specific rate. Vacuum furnaces achieve this with extreme precision, often by backfilling the chamber with a high-purity inert gas like nitrogen or argon.

Powerful fans circulate this gas to provide a fast, uniform, and highly controllable quench that can be tailored to the exact requirements of the material.

Integrated and Automated Processes

A vacuum furnace is an all-in-one solution. A single, fully automated cycle can include pre-heating, austenitizing, inert gas quenching, and even subsequent tempering cycles.

This high degree of electromechanical integration and computer control ensures that every part in a batch—and every subsequent batch—receives the exact same treatment, guaranteeing high repeatability and pass rates.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heat-treating needs. Objectivity requires acknowledging its specific limitations.

Higher Initial Investment

Vacuum furnaces represent a significant capital expenditure. The cost of the chamber, high-power heating elements, complex vacuum pumping systems, and sophisticated controls is substantially higher than that of conventional atmospheric furnaces.

Cycle Time Considerations

Achieving a deep vacuum (the "pump-down") takes time. This initial step adds to the overall cycle time compared to atmospheric furnaces, which can be a factor in high-volume, low-margin production environments.

Maintenance Complexity

The systems that make a vacuum furnace so effective—the pumps, seals, valves, and control instrumentation—require specialized and diligent maintenance to ensure peak performance and prevent costly downtime.

Making the Right Choice for Your Goal

Selecting the correct heat treatment technology depends entirely on the requirements of your component and your operational goals.

- If your primary focus is surface integrity and final part quality: The vacuum furnace is superior for producing parts with zero oxidation, decarburization, or contamination, yielding the best possible metallurgical properties.

- If your primary focus is high-volume production of non-critical parts: The lower cost and potentially faster floor-to-floor time of a conventional atmospheric furnace may be a more economical choice.

- If your primary focus is treating advanced or sensitive materials: For tool steels, superalloys, or complex brazed assemblies, the precise control and pure environment of a vacuum furnace are non-negotiable.

Ultimately, choosing a vacuum furnace is an investment in process control, consistency, and the final quality of your components.

Summary Table:

| Application | Key Benefit |

|---|---|

| Annealing | Prevents oxidation and decarburization |

| Hardening | Ensures uniform heating and precise cooling |

| Brazing | Maintains surface integrity and cleanliness |

| Degassing | Removes contaminants for improved material purity |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise performance for critical thermal processes, delivering superior metallurgical outcomes with zero contamination. Contact us today to discuss how our solutions can enhance your material quality and operational efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision