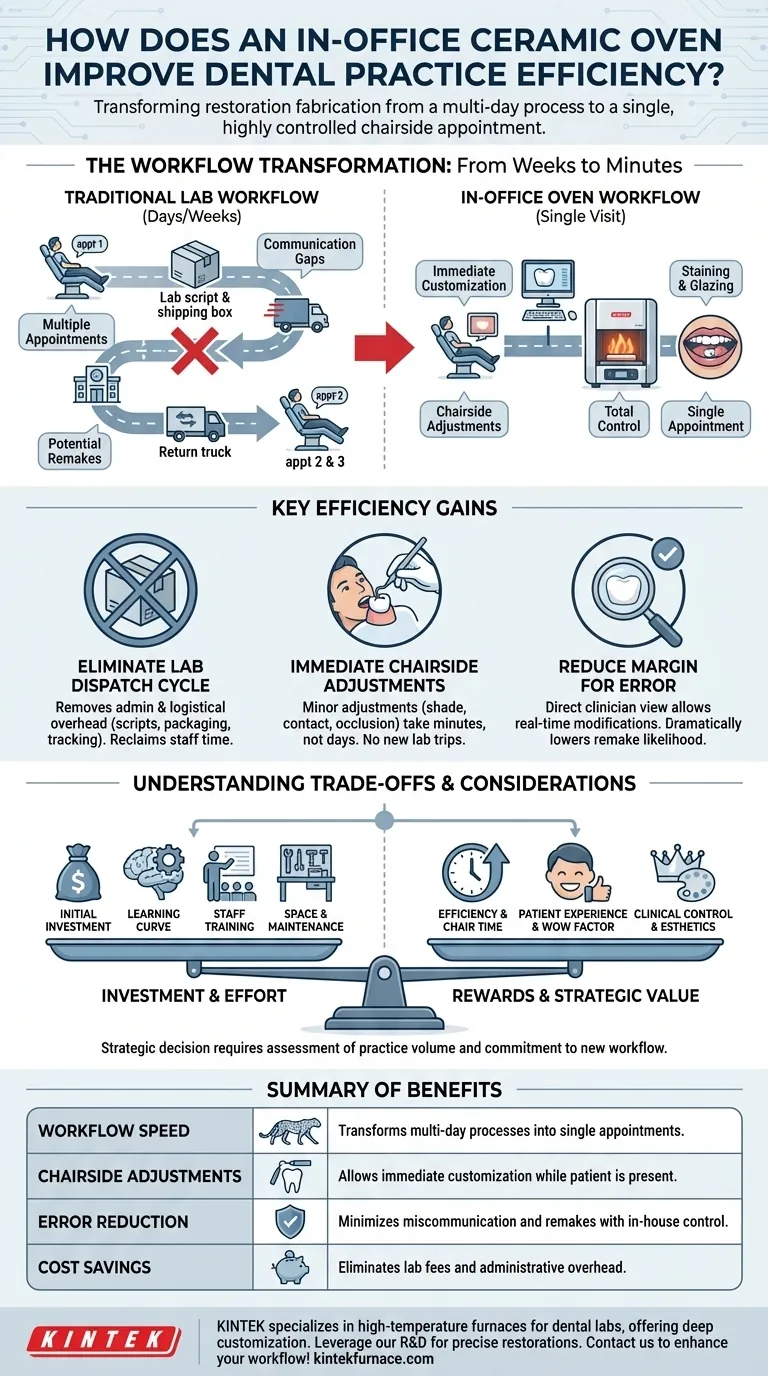

In short, an in-office ceramic oven makes a dental practice more efficient by bringing the final stages of restoration fabrication chairside. This allows for immediate customization, staining, glazing, and adjustments, which eliminates the logistical delays, communication gaps, and potential remakes associated with sending prosthetics to an external laboratory.

The core problem with traditional lab-based restorations is the broken workflow—multiple appointments and logistical hurdles for minor adjustments. An in-office oven closes this loop, transforming a multi-day or multi-week process into a single, highly controlled appointment.

The Workflow Transformation: From Weeks to Minutes

The primary efficiency gain is not just speed, but the radical simplification of the restorative workflow. Owning the final step—the firing of the ceramic—removes multiple points of failure and delay.

Eliminating the Lab Dispatch Cycle

Traditionally, a restoration is sent to a lab, which involves administrative and logistical overhead. This includes creating a lab script, packaging the case, arranging for pickup, and tracking its return.

An in-office oven completely removes this cycle. The time and staff resources previously spent on managing lab cases are reclaimed for patient-facing or revenue-generating activities.

Immediate Chairside Adjustments

The most significant bottleneck is often the need for minor adjustments. A slightly off shade, a tight interproximal contact, or a high occlusal point requires a new lab trip and another patient appointment.

With an in-office oven, these adjustments take minutes. You can add contact ceramic, adjust the shade with a new stain, or re-glaze a surface after an occlusal adjustment, all while the patient is still in the chair.

Reducing the Margin for Error

The back-and-forth between a practice and a lab introduces opportunities for miscommunication. Digital scans and photos help, but nothing replaces the dentist’s ability to see the restoration in the patient's mouth and make real-time modifications.

By handling the final characterization in-house, you gain absolute control over the final product, dramatically reducing the likelihood of a costly and time-consuming remake.

Understanding the Trade-offs and Considerations

While powerful, integrating a ceramic oven requires a strategic assessment. It is not a simple plug-and-play solution and introduces new responsibilities.

The Initial Investment and Learning Curve

A high-quality ceramic oven represents a significant capital investment. The return on this investment depends entirely on your practice's volume of ceramic restorations and your commitment to a new workflow.

Furthermore, there is a learning curve. Achieving predictable, esthetic results requires training and practice in staining and glazing techniques. Your team must become proficient to realize the full benefit.

Staff Training and Workflow Integration

Your clinical team must be trained to operate the oven and handle the materials safely and effectively. The workflow for a single-visit restoration is fundamentally different from a traditional one.

Integrating this new process requires careful planning to ensure it doesn't create bottlenecks elsewhere, such as at the milling unit or in sterilization.

Space and Maintenance

These ovens require dedicated counter space and proper ventilation. They also have ongoing maintenance needs, including calibration and periodic replacement of heating elements, which must be factored into the operational cost.

Making the Right Choice for Your Practice

Integrating an in-office oven is a strategic decision that should align with your specific practice goals.

- If your primary focus is maximizing efficiency: The key benefit is the ability to complete restorations in a single visit, freeing up chair time and reducing administrative overhead.

- If your primary focus is patient experience: Offering single-visit crowns is a powerful differentiator that respects patients' time and provides a "wow" factor.

- If your primary focus is clinical control and esthetics: The oven gives you the final say as the clinician, allowing you to perfect shade, contour, and texture chairside for superior results.

Ultimately, an in-office oven empowers you to take full ownership of the final restorative outcome.

Summary Table:

| Benefit | Description |

|---|---|

| Workflow Speed | Transforms multi-day processes into single appointments, saving time and resources. |

| Chairside Adjustments | Allows immediate customization, staining, and glazing while the patient is present. |

| Error Reduction | Minimizes miscommunication and remakes by keeping control in-house. |

| Cost Savings | Eliminates lab fees and administrative overhead for managing external cases. |

Ready to elevate your dental practice with advanced ceramic solutions? KINTEK specializes in high-temperature furnaces tailored for dental labs, offering products like Muffle and Tube Furnaces with deep customization to meet your unique needs. Leverage our R&D and in-house manufacturing for precise, efficient restorations—contact us today to discuss how we can enhance your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 1200℃ Muffle Oven Furnace for Laboratory

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab