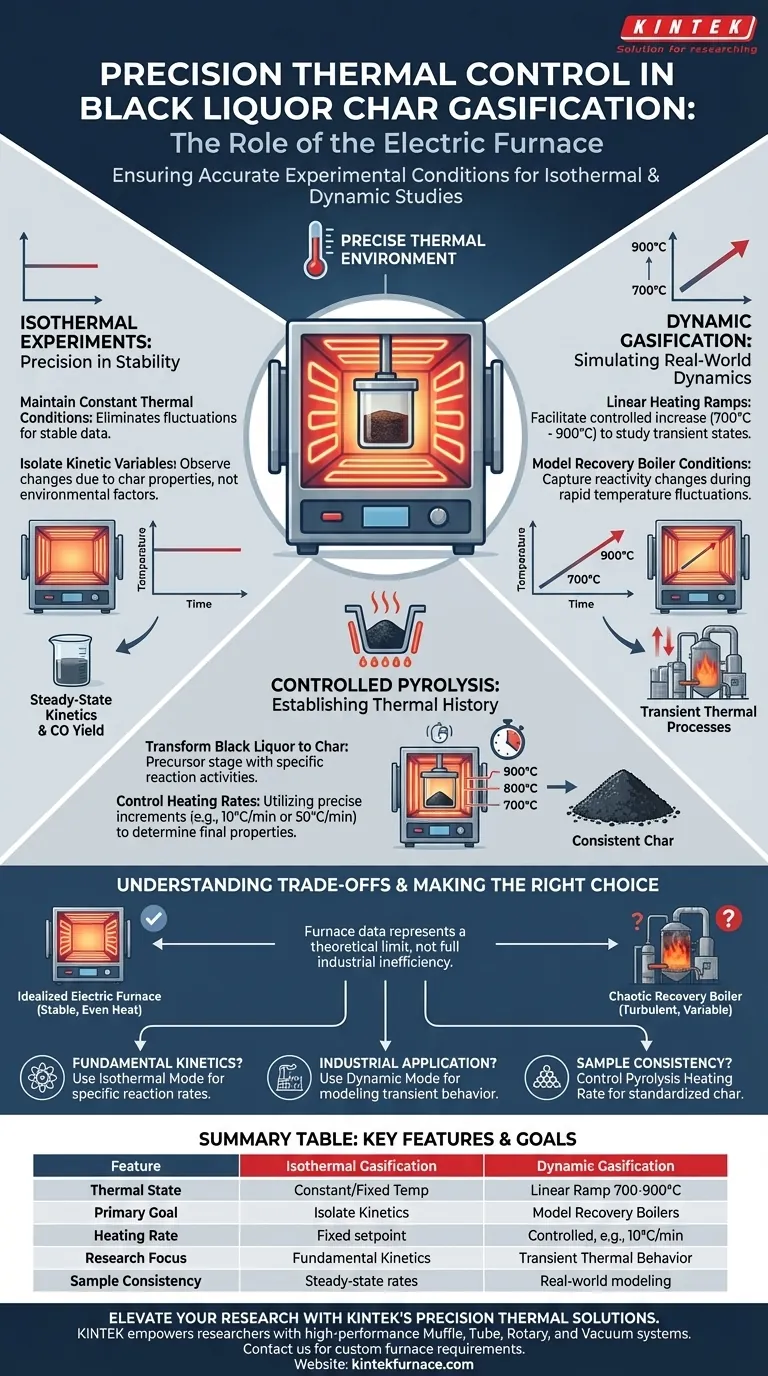

The electric furnace acts as a precision instrument that dictates the accuracy of black liquor char gasification data by strictly controlling the thermal environment. It ensures experimental validity by maintaining a fixed, constant temperature during isothermal tests or executing a precise linear heating ramp—specifically from 700 to 900 degrees Celsius—during dynamic experiments.

The electric furnace provides the necessary control to isolate temperature as a variable, allowing researchers to simulate the complex, transient thermal processes of industrial recovery boilers within a controlled laboratory setting.

Precision in Isothermal Experiments

Maintaining Constant Thermal Conditions

In isothermal gasification, the primary requirement is stability. The electric furnace is programmed to reach and rigidly maintain a specific setpoint temperature.

This constant environment eliminates thermal fluctuations that could skew data. By keeping the temperature fixed, researchers can accurately evaluate how specific temperatures directly influence the yield of carbon monoxide (CO) and other reaction products.

Isolating Kinetic Variables

By removing temperature variance, the furnace ensures that any observed changes in reaction rates are due to the chemical properties of the char, not external environmental factors. This allows for the precise calculation of reaction kinetics under steady-state conditions.

Simulating Real-World Dynamics

Linear Heating Ramps

Real-world industrial processes are rarely static. To study these transient states, the electric furnace is used in a dynamic mode to facilitate linear heating.

According to the primary data, the furnace ramps the temperature specifically from 700 to 900 degrees Celsius. This controlled increase allows researchers to observe the char's behavior as it transitions through critical thermal zones.

Modeling Recovery Boiler Conditions

The ultimate goal of dynamic gasification is to simulate the environment inside a recovery boiler. These boilers experience rapid temperature changes rather than a single fixed heat.

By using the electric furnace to mimic these transient thermal processes, researchers can capture reactivity changes across various temperature intervals. This provides data that is far more applicable to actual industrial operations than static testing alone.

The Role of Controlled Pyrolysis

Establishing Thermal History

Before gasification can occur, the black liquor must be converted into char. The electric furnace is also utilized in this precursor stage to transform dried black liquor into char with specific reaction activities.

Controlling Heating Rates

The furnace controls the heating rates during this pyrolysis stage, utilizing precise increments such as 10°C/min or 50°C/min.

This precision is critical because the thermal history of the char dictates its final physicochemical properties. By strictly controlling the initial heating environment, the furnace ensures the foundational material used for gasification research is consistent and reproducible.

Understanding the Trade-offs

Idealized vs. Chaotic Environments

While an electric furnace provides high precision, it creates an "ideal" environment. It delivers steady heat conduction from the interior to the exterior, ensuring the sample reaches its ignition point evenly.

However, industrial recovery boilers are turbulent and chaotic. The data gathered from a calm, electrically heated furnace represents a baseline theoretical limit. It may not fully capture the inefficiencies or mechanical variables present in large-scale industrial machinery.

Making the Right Choice for Your Goal

To maximize the value of your experimental data, choose the furnace operation mode that aligns with your specific research objectives.

- If your primary focus is fundamental kinetics: Use Isothermal Mode to determine specific reaction rates and CO yields at fixed temperatures without the interference of thermal transients.

- If your primary focus is industrial application: Use Dynamic Mode with linear heating (700-900°C) to model how the char will react during the changing thermal conditions of a recovery boiler.

- If your primary focus is sample consistency: Ensure the furnace controls the pyrolysis heating rate (e.g., 10°C/min) to standardize the char's physicochemical properties before gasification begins.

Precise thermal control is the bridge between theoretical chemistry and practical industrial optimization.

Summary Table:

| Feature | Isothermal Gasification | Dynamic Gasification |

|---|---|---|

| Thermal State | Constant/Fixed Temperature | Linear Heating Ramp (700-900°C) |

| Primary Goal | Isolate kinetic variables & CO yield | Model industrial recovery boilers |

| Heating Rate | Fixed setpoint stability | Controlled (e.g., 10°C/min or 50°C/min) |

| Research Focus | Fundamental reaction kinetics | Transient thermal behavior |

| Sample Consistency | Steady-state reaction rates | Real-world application modeling |

Elevate Your Research with KINTEK’s Precision Thermal Solutions

Precise thermal control is the vital bridge between theoretical chemistry and industrial success. KINTEK empowers researchers with high-performance Muffle, Tube, Rotary, and Vacuum systems designed to handle the most demanding isothermal and dynamic gasification studies.

Our equipment, backed by expert R&D and specialized manufacturing, ensures your lab can replicate industrial conditions with absolute accuracy. Whether you need standard CVD systems or fully customizable high-temp furnaces tailored to your unique black liquor char research, KINTEK delivers the consistency your data demands.

Ready to optimize your experimental thermal history? Contact KINTEK today to discuss your custom furnace requirements with our specialists!

Visual Guide

References

- Fernando Leo Bueno - CO₂ Gasification of Black Liquor Char under isothermal and dynamic conditions. DOI: 10.26754/jji-i3a.202512148

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying

- Why is pre-sintering of Ga2O3 raw material powder required? Unlock Beta-Phase Stability for High-Performance Thin Films

- How does a needle valve control silver foil surface quality for graphene growth? Prevent defects with pressure control.

- How do water quenching and furnace cooling methods differ in their application to high-entropy alloys? Expert Insights

- What methods are used to analyze and characterize graphene samples? Unlock Key Techniques for Accurate Material Analysis

- What are the advantages of using a vacuum drying oven for magnesium slag? Preserving Sample Integrity

- Why is a constant temperature and humidity curing chamber essential for geopolymerization? Ensure Structural Strength

- What is the primary function of an industrial-grade electric oven for concrete? Optimize High-Temp Material Testing