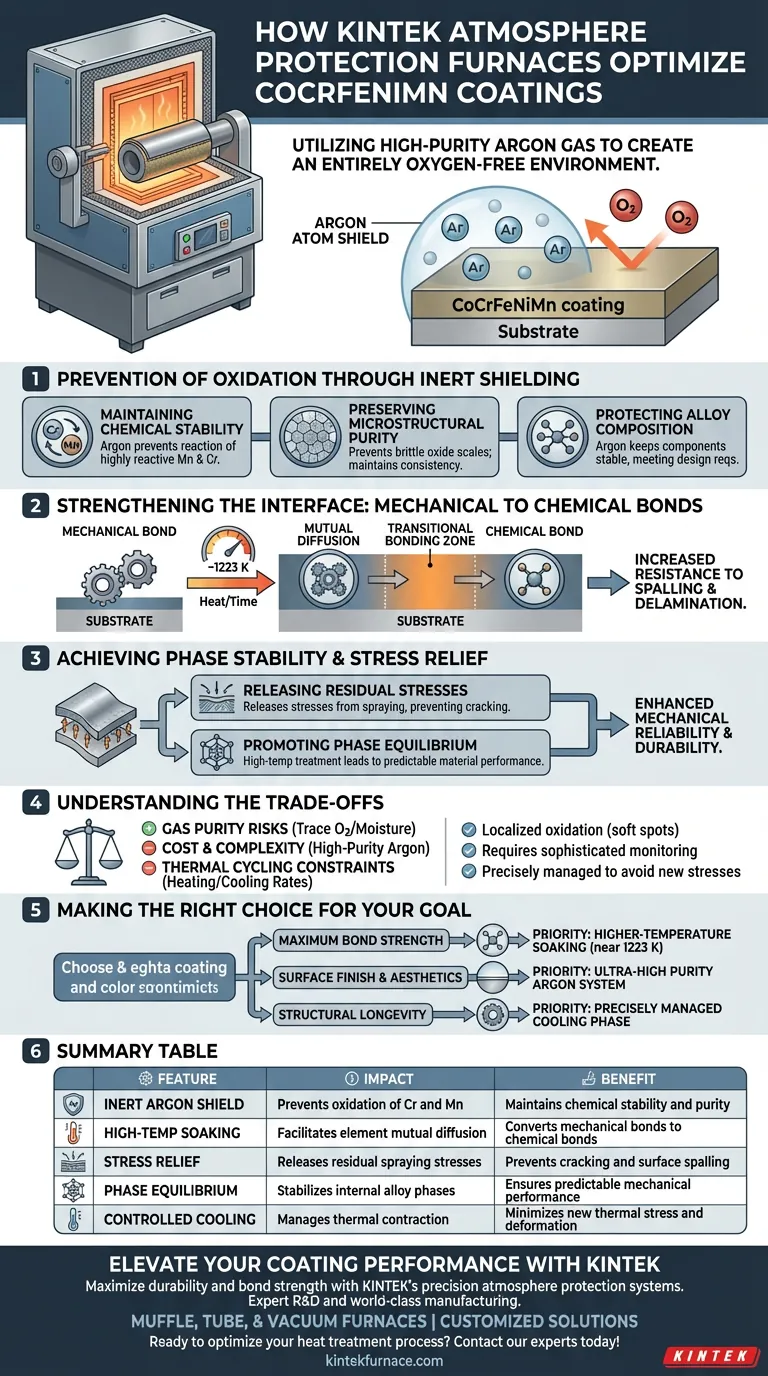

Atmosphere protection furnaces safeguard CoCrFeNiMn coatings by utilizing high-purity argon gas to create an entirely oxygen-free environment. This inert shield prevents high-temperature oxidation, preserving the coating's chemical stability and ensuring the purity of its microstructure.

By eliminating oxygen, the furnace allows the coating to undergo critical metallurgical changes—such as element diffusion and stress relief—without the risk of surface degradation or composition loss.

Prevention of Oxidation through Inert Shielding

Maintaining Chemical Stability

The primary role of the furnace is to provide an oxygen-free environment using high-purity argon. This is vital for CoCrFeNiMn alloys, as elements like manganese and chromium are highly reactive at elevated temperatures.

Preserving Microstructural Purity

By preventing oxidation reactions, the furnace ensures the microstructure remains consistent throughout the heat treatment process. This prevents the formation of brittle oxide scales that would otherwise compromise the coating's integrity.

Protecting the Alloy Composition

Without this protective medium, the chemical profile of the CoCrFeNiMn coating would shift. The argon atmosphere keeps the alloy components stable, ensuring the final product meets its specific design requirements.

Strengthening the Interface: From Mechanical to Chemical Bonds

Facilitating Mutual Diffusion

At high temperatures, such as 1223 K, the controlled atmosphere allows for the mutual diffusion of elements between the coating and the substrate. This process is only effective if the surface remains free of oxide barriers.

Creating a Transitional Bonding Zone

This diffusion results in a transitional bonding zone that integrates the coating into the substrate material. This zone is the foundation of a robust, long-lasting surface application.

Converting Bond Types

The heat treatment process successfully converts the original mechanical bond into a much stronger chemical bond. This transition significantly increases the coating’s resistance to spalling and delamination under stress.

Achieving Phase Stability and Stress Relief

Releasing Residual Stresses

The spraying process used to apply coatings often introduces significant residual stresses. The furnace provides the thermal energy needed to release these stresses, preventing future cracking or deformation.

Promoting Phase Equilibrium

High-temperature treatment helps the internal phases of the CoCrFeNiMn coating reach an equilibrium state. This results in a more predictable and reliable material performance in real-world applications.

Enhancing Mechanical Reliability

By combining stress relief with phase stability, the furnace produces a coating that is physically tougher. This makes the treated blades or components far more durable in high-stress environments.

Understanding the Trade-offs

Gas Purity and Contamination Risks

The effectiveness of the furnace is entirely dependent on the purity of the argon gas. Even trace amounts of oxygen or moisture can cause localized oxidation, leading to "soft spots" in the coating's protection.

Cost and Complexity

Operating an atmosphere protection furnace is more expensive than standard heat treatment due to the continuous consumption of high-purity inert gas. It also requires sophisticated monitoring equipment to ensure the atmosphere remains stable throughout the cycle.

Thermal Cycling Constraints

While heat treatment improves bonding, the heating and cooling rates must be precisely managed. Rapid temperature changes can induce new thermal stresses, potentially undoing the benefits of the stress-relief process.

Making the Right Choice for Your Goal

If you are managing a heat treatment project for CoCrFeNiMn coatings, consider these strategic priorities:

- If your primary focus is maximum bond strength: Prioritize higher-temperature soaking periods (near 1223 K) to maximize the transition from mechanical to chemical bonding.

- If your primary focus is surface finish and aesthetics: Ensure your argon delivery system is rated for ultra-high purity to eliminate any possibility of surface discoloration from oxidation.

- If your primary focus is structural longevity: Focus on the cooling phase of the furnace cycle to ensure that phase equilibrium is maintained without introducing new thermal shocks.

Through the precise control of an inert atmosphere, these furnaces transform a vulnerable surface layer into a high-performance, chemically bonded protective shield.

Summary Table:

| Feature | Impact on CoCrFeNiMn Coating | Benefit to Final Product |

|---|---|---|

| Inert Argon Shield | Prevents oxidation of Cr and Mn | Maintains chemical stability and purity |

| High-Temp Soaking | Facilitates element mutual diffusion | Converts mechanical bonds to chemical bonds |

| Stress Relief | Releases residual spraying stresses | Prevents cracking and surface spalling |

| Phase Equilibrium | Stabilizes internal alloy phases | Ensures predictable mechanical performance |

| Controlled Cooling | Manages thermal contraction | Minimizes new thermal stress and deformation |

Elevate Your Coating Performance with KINTEK

Maximize the durability and bond strength of your CoCrFeNiMn coatings with KINTEK’s precision atmosphere protection systems. Backed by expert R&D and world-class manufacturing, we provide high-purity Muffle, Tube, and Vacuum furnaces designed to eliminate oxidation and ensure metallurgical excellence. Whether you need standard lab equipment or a customized high-temperature solution for unique material requirements, KINTEK delivers the thermal precision your research demands.

Ready to optimize your heat treatment process? Contact our experts today to find the perfect furnace for your lab!

Visual Guide

References

- Bo Zhang, Yu Li. The Effect of Heat Treatment on the Microstructure and Mechanical Properties of Plasma-Cladded CoCrFeNiMn Coatings on Compacted Graphite Iron. DOI: 10.3390/coatings14040374

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What core processing conditions does a tube atmosphere furnace provide? Key Factors for fMC Carbonization

- What is the purpose of a chemically inert atmosphere in a furnace? Protect Materials from Oxidation & Contamination

- What are some common gases and vapors used in furnace atmospheres? Optimize Your Heat Treatment Process

- How does the design of a convector plate affect the thermal efficiency? Maximize Bell-Type Annealing Performance

- Why would a heat treatment process require an inert atmosphere furnace? Prevent Oxidation and Ensure Material Integrity

- Why Calcination of Carbon-Supported Nickel Catalysts Needs Inert Gas? Protect Your Support Structure

- How does a precision temperature-controlled annealing furnace influence the grain size of TWIP steel?

- What are the main types of nitrogen-based furnace atmospheres? Optimize Your Heat Treatment Process