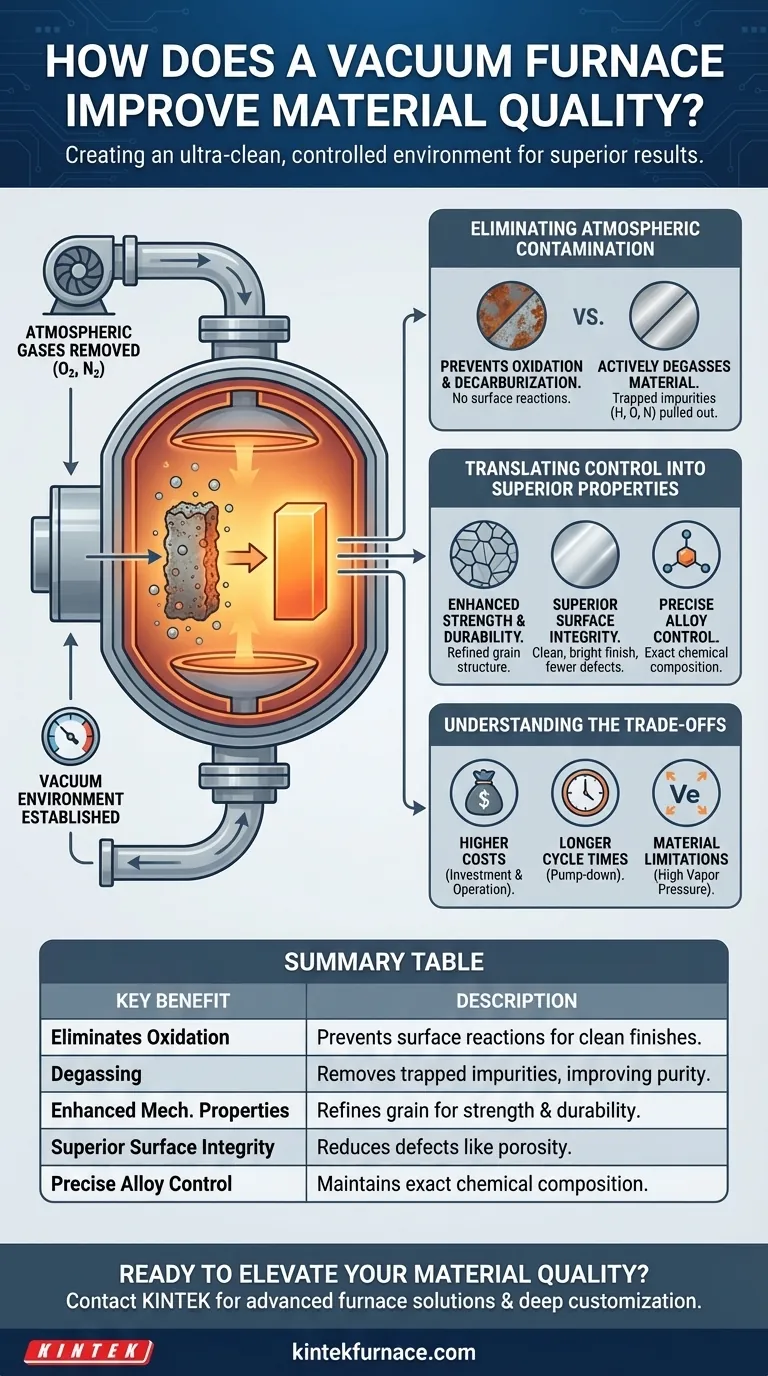

At its core, a vacuum furnace improves material quality by creating an ultra-clean, controlled environment. By removing atmospheric gases like oxygen and nitrogen, it prevents unwanted chemical reactions such as oxidation and contamination during high-temperature processing. This allows for heat treatment that not only protects the material's integrity but actively enhances its fundamental properties.

The crucial insight is that a vacuum furnace does more than just heat a material. By creating a low-pressure environment, it gives engineers precise control over the material's chemistry and microstructure, eliminating defects that are unavoidable in conventional atmosphere-based heating.

The Fundamental Principle: Why a Vacuum Matters

A vacuum furnace operates by using pumps to remove air and other gases from a sealed chamber before heating begins. This creates a low-pressure environment where very few gas molecules are left to interact with the material being processed.

Eliminating Atmospheric Contamination

The most immediate benefit is the prevention of oxidation. At high temperatures, metals readily react with oxygen in the air, forming a brittle oxide layer that compromises surface finish, structural integrity, and mechanical properties.

A vacuum environment virtually eliminates this threat. This is also true for other reactions, such as decarburization, where carbon can leave the surface of steel, making it softer and weaker.

Actively Degassing the Material

Beyond preventing surface reactions, a vacuum can actively pull trapped impurities out from within the material itself.

Elements like hydrogen, oxygen, and nitrogen, which can be introduced during initial melting and casting, are drawn out of the metal. This degassing process results in a purer, denser material with significantly fewer internal defects.

Translating Control into Superior Properties

The pristine environment of a vacuum furnace is the foundation for achieving specific, desirable material characteristics that are critical for high-performance applications.

Enhanced Mechanical Strength and Durability

Processes like vacuum annealing and tempering allow for precise thermal cycles that refine a metal's internal grain structure. This relieves internal stresses, increases ductility, and improves overall tensile strength and fatigue resistance.

Without the risk of oxidation, these thermal treatments can be optimized purely for metallurgical performance, leading to components that are stronger and last longer.

Superior Surface Integrity

Vacuum processing yields components with a bright, clean surface finish, free from the scale and discoloration caused by atmospheric reactions.

More importantly, it minimizes microscopic defects like porosity and inclusions. This is critical for applications in aerospace and medical implants, where even a tiny flaw can be a point of failure.

Precise Control Over Alloy Composition

For advanced alloys used in electronics or aerospace, exact chemical composition is non-negotiable. A vacuum ensures that no unwanted elements from the atmosphere are introduced during heating or melting.

This allows for the precise manipulation of alloying elements to achieve specific electrical, magnetic, or thermal properties with exceptional consistency.

Understanding the Trade-offs

While the benefits are significant, a vacuum furnace is not the universal solution for all heat treatment. Understanding its limitations is key to making an informed decision.

Higher Initial Investment and Operating Costs

Vacuum furnaces are complex systems. The high-powered pumps, robust chamber seals, and sophisticated control systems result in a higher capital investment compared to traditional atmosphere furnaces. They also require more maintenance and skilled operation.

Cycle Time Considerations

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber before heating can add to the total cycle time. For high-volume production, this can make batch vacuum processing less efficient than continuous atmosphere-based systems.

Material Limitations

Not all materials are suitable for vacuum processing. At high temperatures and low pressures, some elements with a high vapor pressure can begin to "boil off" the material's surface. This phenomenon, known as outgassing, must be considered when selecting process parameters.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on the required quality, performance, and cost constraints of your final product.

- If your primary focus is maximum purity and performance (aerospace, medical, electronics): A vacuum furnace is essential for eliminating defects and achieving the highest possible material properties.

- If your primary focus is surface finish and aesthetics (jewelry, decorative hardware): Vacuum processing provides a bright, clean finish directly out of the furnace, eliminating the need for aggressive post-processing.

- If your primary focus is cost-effective hardening or stress relief with moderate tolerances: A controlled atmosphere (e.g., nitrogen or argon) furnace may provide an acceptable balance between cost and quality if minor surface oxidation is permissible.

Ultimately, choosing a vacuum furnace is an investment in achieving a level of material quality and reliability that other methods cannot replicate.

Summary Table:

| Key Benefit | Description |

|---|---|

| Eliminates Oxidation | Prevents surface reactions by removing oxygen, ensuring clean, bright finishes. |

| Degassing | Removes trapped impurities like hydrogen, improving material purity and density. |

| Enhanced Mechanical Properties | Refines grain structure for increased strength, ductility, and fatigue resistance. |

| Superior Surface Integrity | Reduces defects like porosity, critical for aerospace and medical implants. |

| Precise Alloy Control | Maintains exact chemical composition without atmospheric contamination. |

Ready to elevate your material quality with advanced vacuum furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with high-temperature furnace solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety