A Vacuum Drying Oven is the critical tool for solidifying composite films by using low pressure to significantly lower solvent boiling points. This facilitates the complete removal of residual organic solvents—such as acetonitrile or acetone—at safe, low temperatures, ensuring the film forms a dense, defect-free structure without thermal damage.

Core Takeaway The vacuum drying process does more than just dry; it actively engineers the film’s microstructure. By enabling low-temperature dehydration, it prevents the formation of voids and cracks while ensuring the chemical purity required to maintain a wide electrochemical window and stable ionic conductivity.

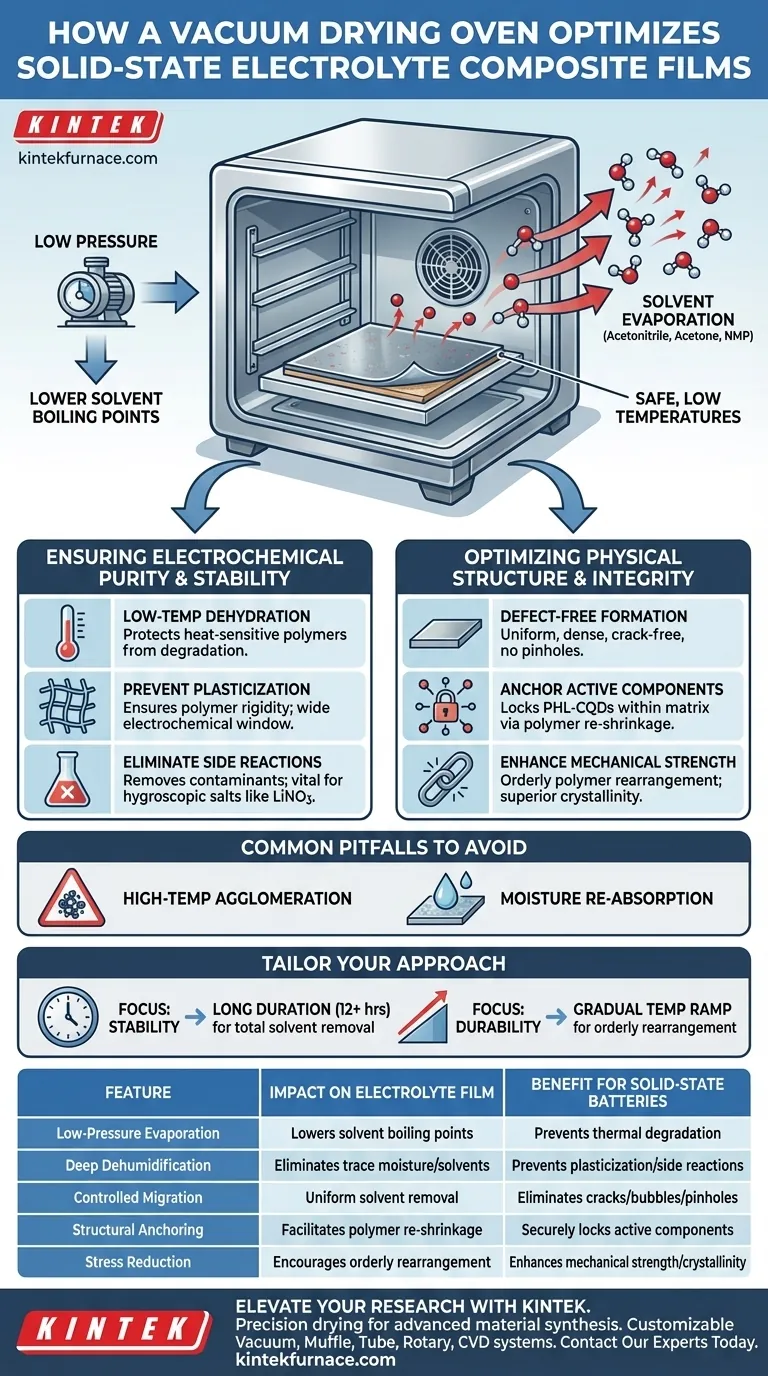

Ensuring Electrochemical Purity and Stability

The Mechanism of Low-Temperature Dehydration

By operating in a vacuum, the oven reduces the ambient pressure, which depresses the boiling point of solvents like water, NMP, and acetonitrile. This allows these solvents to evaporate rapidly at much lower temperatures than would be required under atmospheric conditions. This protects heat-sensitive polymer components from degradation during the drying phase.

Preventing Solvent-Induced Plasticization

Thorough removal of trace solvents is essential to prevent the "plasticization" of the polymer matrix. If solvents remain, they soften the polymer, which can dangerously narrow the electrochemical window. Vacuum drying ensures the polymer remains rigid and chemically stable, guaranteeing reproducible experimental data.

Eliminating Side Reactions

Residual organic solvents are not merely impurities; they are active contaminants that can trigger unwanted side reactions during battery operation. By achieving deep dehumidification and solvent removal, the vacuum oven eliminates these variables. This is particularly vital for films containing hygroscopic salts like Lithium Nitrate (LiNO3), which must be strictly isolated from moisture.

Optimizing Physical Structure and Integrity

Defect-Free Film Formation

Drying at atmospheric pressure often causes solvents to boil violently or evaporate unevenly, leading to surface cracks, bubbles, or pinholes. The vacuum environment promotes a controlled migration of solvents from the film's interior to the surface. This results in a composite film that is uniform, flat, and structurally dense.

Anchoring Active Components

The vacuum drying process drives the re-shrinkage of swollen polymer networks as the solvent exits. This physical contraction plays a functional role: it securely anchors internal components, such as Phloroglucinol-based carbon quantum dots (PHL-CQDs), within the matrix. This "locking" effect prevents active materials from leaching out during the battery's lifecycle.

Enhancing Mechanical Strength

Beyond simple drying, the controlled heat and vacuum environment facilitates the orderly rearrangement of polymer chains. This alignment reduces internal stress within the material. The result is a film with superior crystallinity and mechanical strength, making it more durable under operational stress.

Common Pitfalls to Avoid

Risk of Agglomeration at High Temperatures

While vacuum allows for lower temperatures, applying excessive heat can still damage sensitive components. For films containing metallic nanoparticles, strict temperature control is required to prevent agglomeration or surface oxidation, which would reduce the effective electrochemical active surface area.

Moisture Re-absorption

The benefits of vacuum drying are immediately lost if the sample is exposed to air post-processing. Because solid polymer electrolytes are often hygroscopic, breaking the vacuum without a proper transfer protocol can lead to immediate water absorption. This degrades the film's mechanical integrity and compromises subsequent impedance spectroscopy testing.

Making the Right Choice for Your Goal

To maximize the effectiveness of your vacuum drying process, tailor your approach to your specific performance metrics:

- If your primary focus is Electrochemical Stability: Prioritize long duration drying (e.g., 12+ hours) to ensure the total removal of solvents like acetonitrile, preventing plasticization and side reactions.

- If your primary focus is Structural Durability: Focus on a gradual ramp-up of temperature within the vacuum to promote orderly polymer chain rearrangement and secure anchoring of filler materials.

Ultimately, the vacuum drying oven is not just a drying device, but a structural synthesis tool that defines the density, purity, and longevity of your solid-state electrolyte.

Summary Table:

| Feature | Impact on Electrolyte Film Formation | Benefit for Solid-State Batteries |

|---|---|---|

| Low-Pressure Evaporation | Lowers solvent boiling points (Acetonitrile, NMP) | Prevents thermal degradation of sensitive polymers |

| Deep Dehumidification | Eliminates trace moisture and residual solvents | Prevents plasticization and unwanted side reactions |

| Controlled Migration | Promotes uniform solvent removal from interior to surface | Eliminates cracks, bubbles, and surface pinholes |

| Structural Anchoring | Facilitates polymer network re-shrinkage | Securely locks active components (e.g., PHL-CQDs) |

| Stress Reduction | Encourages orderly rearrangement of polymer chains | Enhances mechanical strength and crystallinity |

Elevate Your Solid-State Battery Research with KINTEK

Precision in the drying stage is the difference between a failing cell and a breakthrough. KINTEK provides high-performance vacuum systems designed specifically for the rigorous demands of advanced material synthesis.

Backed by expert R&D and manufacturing, KINTEK offers Vacuum Drying Ovens, Muffle, Tube, Rotary, and CVD systems, all fully customizable to meet your unique laboratory needs. Whether you are aiming for a wider electrochemical window or superior mechanical durability, our equipment ensures your composite films are dense, pure, and defect-free.

Ready to optimize your electrolyte synthesis? Contact our experts today to find the perfect thermal solution for your lab.

Visual Guide

References

- Jian Ouyang, Zenglin Wang. Tungsten Carbide/Tungsten Oxide Catalysts for Efficient Electrocatalytic Hydrogen Evolution. DOI: 10.3390/molecules30010084

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Induction Melting Furnace

People Also Ask

- What features contribute to the high degree of electromechanical integration in a vacuum furnace? Unlock Precision and Automation

- Why is vacuum arc melting equipment used for TaC and TiC reinforced alloys? Achieving Purity and Thermal Precision

- How does a high-performance sintering furnace impact PZT ceramics at 1200°C? Achieve 99% Density and Maximize d33

- How is vacuum brazing applied in the medical field? Achieve Superior Biocompatibility and Strength for Devices

- What is the function of a vacuum drying oven in rice husk carbonization? Ensure Chemical Stability & Material Integrity

- What is the primary purpose of vacuum sealing raw materials for alpha-Mg3Bi2 crystal growth? Ensure Purity and Safety

- How does a vacuum furnace facilitate precise control of tellurium vacancy concentrations in PtTe2 thin films?

- How does heat transfer differ in vacuum vs. air furnaces? Key Insights for Your Lab